Surface finishes

Bead blasting services

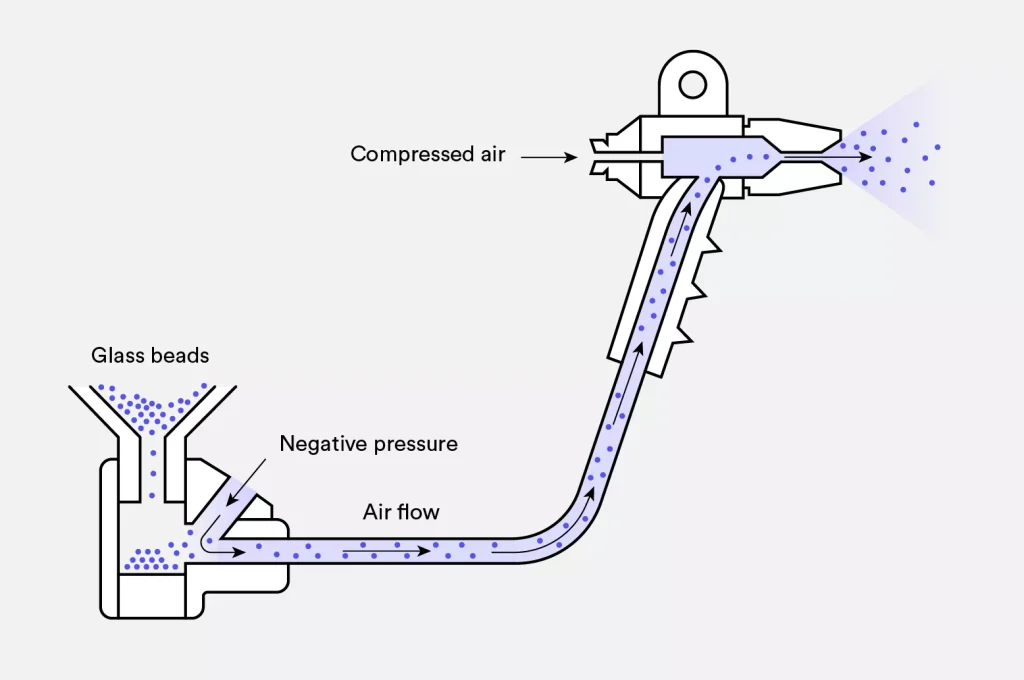

Bead blasting is a specialized process that uses high-pressure air to blast media particles at a surface. The result is a smooth, even finish with no visible brushstrokes or other imperfections. Bead blasting is often used on metal surfaces to prepare them for painting or plating. It can also be used to create a matte finish on glass or plastic.

Introduction To Bead Blasting Finishing

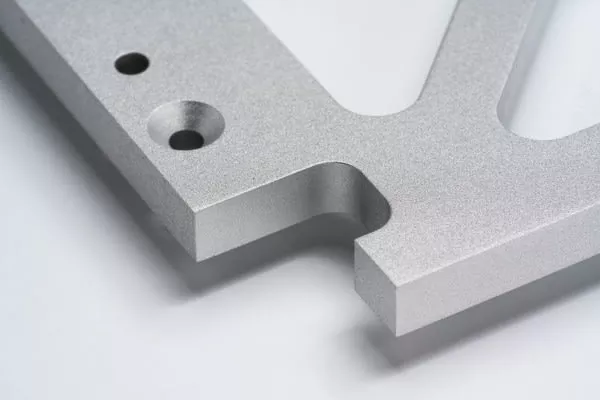

Bead blasting is used to add a matte or satin surface finish to a CNC machined part. During this process, a pressurized air gun shoots millions of glass beads at the part, effectively removing tool marks and imperfections, creating a consistent grainy finish. In contrast to other finishes, including anodizing and powder coating, bead blasting adds no chemical or mechanical properties to the part — it’s purely visual. Unlike powder coating, which adds material to a part, bead blasting is a reductive finish, meaning it removes material from the part. This is an important consideration if your part has strict tolerances.

Bead blasting is one of the most affordable surface finishes, but it must be executed manually. As such, those considering bead blasting as a surface finish should be prepared to incur the cost of engaging an operator who has been formally trained in this process, and recognize that the final result will largely depend on how skilled the operator is. Bead size and grade will also affect the final finish.

Bead blasted Service Key Properties

Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. This is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets. Our standard grit is #120.

| Features | Info |

|---|---|

| Materials for bead blasted part | ABS, Aluminum, Brass, Stainless Steel, Steel |

| Color | White glossy |

| Texture | Matte |

| Thickness | n/a |

Glass Bead blasting

Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. In glass bead blasting, round glass beads in various grain sizes are used instead of sharp-edged sand.

Media or Bead Blasting

Bead blasting is also called “media blasting” because it can use a variety of different media depending on your end goal. The media blasting finishing options available at HLH include glass bead blasting and sandblasting.

Bead Blasted

Bead blasting produces a smooth, shiny surface. Abrasive materials, including aluminum oxide, glass pieces, and steel beads, are mixed with high-speed compressed air in this process. Bead blasting removes all tool marks from surfaces, making them equally matte.

The attached burr gets washed away by the high-pressure air jet angled and directed at the part’s surface. It applies to claims made. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Benefits Of Choosing Our Bead Blasting Services

Enhanced Aesthetics

Our bead blasting services ensure that CNC parts exhibit a uniform, matte finish, free from blemishes and inconsistencies.

Burr and Defect Removal

One of the most practical benefits is the removal of burrs and other minute surface defects that might impair the component’s functionality or assembly compatibility.

Ideal Surface Preparation

Bead blasting acts as a precursor for other treatments. Creating a clean, textured surface facilitates better painting, coating, or anodizing adhesion, ensuring these treatments last longer and look better.

Augmented Wear Resistance

Bead blasted surfaces demonstrate a notable resistance to wear and tear, adding to the longevity of CNC components.