Aluminum sheet metal fabrication is a popular and versatile manufacturing...

Read MoreSheet Metal Fabrication Service

Our industrial sheet metal fabrication shop allows us to shape, bend, cut, shrink, stretch and fuse or weld sheet metal. Fabrication of sheet metal supports metal creation, shaping and joining to repair or develop a tangible component. We use many tools and techniques in the fabrication of sheet metal.

- 50+ Materials.

- 100% Quality Guaranteed.

Rapid Sheet Metal Prototyping And Production

Anpllocnc employs sheet metal technology to bend, punch, and cut standard gauge metals for both rapid prototypes and low to high-volume production runs. What set us apart from other conventional sheet metal shops is our incredible capacity and proficiency in sheet metal manufacturing of end-use and durable metal parts or components coupled with broad material selections and finishes matching your needs.

From prototypes to assemblies to finishing options, Anpllocnc always keeps you traceable with your order and concentrates on every single detail and matter on model designs, user experience online, and each production stage. To help global product developers, designers, and manufacturers grasp more chances in the market, we try our best to shorten the cycle time and ensure on-time delivery to speed up their product launch – whether it’s a one-off prototype or 1,000 production parts.

Why can you trust Anpllocnc?

No matter if a single prototype or ten thousand market-ready parts are being ordered, having trust in your manufacturer is absolutely essential. Parts that are going through the prototyping stage will likely involve intellectual property and trade secrets that need to be kept away from the public eye, and production parts will need to have a great deal of precision so that they are consistent.

Having over of experience in the field of sheet metal fabrication and with over 2 million parts manufactured, our 33,000+ customers continue to use our fabrication services because they know that every part they order will conform to our strict set of capabilities.

Capabilities

- Small Components

- Medium Components

- Outsourcing

- Punching

- Forming

- Shearing

- Grinding

- Finishing

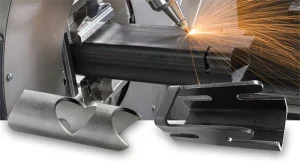

- Welding

- Hardware Insertion

- Cut-Off

- Machining

- Programming/Design

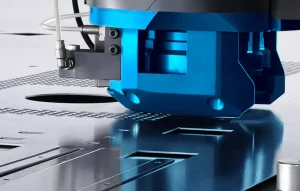

- Laser Cutting

- MIG

- TIG

- Heli-Arc

- Spot

Laser cutting

- Amada 2500kw

Punching

- 20-ton Trumpf TC 2020 FMC CNC Punch with automatic sheet loader

- 30-ton manual CNC Single Station Punch

- 65-ton Piranha Plate Punch

Forming

- Trumpf Trumabend 3’ 20-ton Precision Press Brake with CNC gauging

- Trumpf Trumabend 8’ 95-ton Precision Press Brake with CNC gauging

- Trumpf Trumabend 10’ 130-ton Precision Press Brake with CNC gauging

- 5’ Cincinnati CB II Press Brake with CNC gauging

- 8’ 90-ton Press Brake with CNC gauging

- 50” Power Roll ¼” capacity

Welding

- Robotic Welding Cell 60” Dia. weld table

- 2 Welding Stations featuring MIG & TIG

- 40 KVA Spot Welder

- 5/16” Stud Welder

Shearing & Cutting

- 3/16” X 10’ capacity Squaring Shear

- Powermax-1000 Portable Plasma cutter

Finishing

- 37” belt wet Timesaver

- Edge deburring machine

- 6.5 cubic foot vibratory finisher

- Misc. sanders, grinders, flexible shaft and air powered tools for the finishing of both carbon and stainless steel fabrications

Machine Shop/Tool Room

- Do-All Production Auto Feed Horizontal Saw

- Vertical Band Saw

- Vertical Milling Machine

- 2 Drill Presses

- High Speed Tapping Table

- CNC

- Manual

- Robotic Load/Unload

- Up to 130 ton

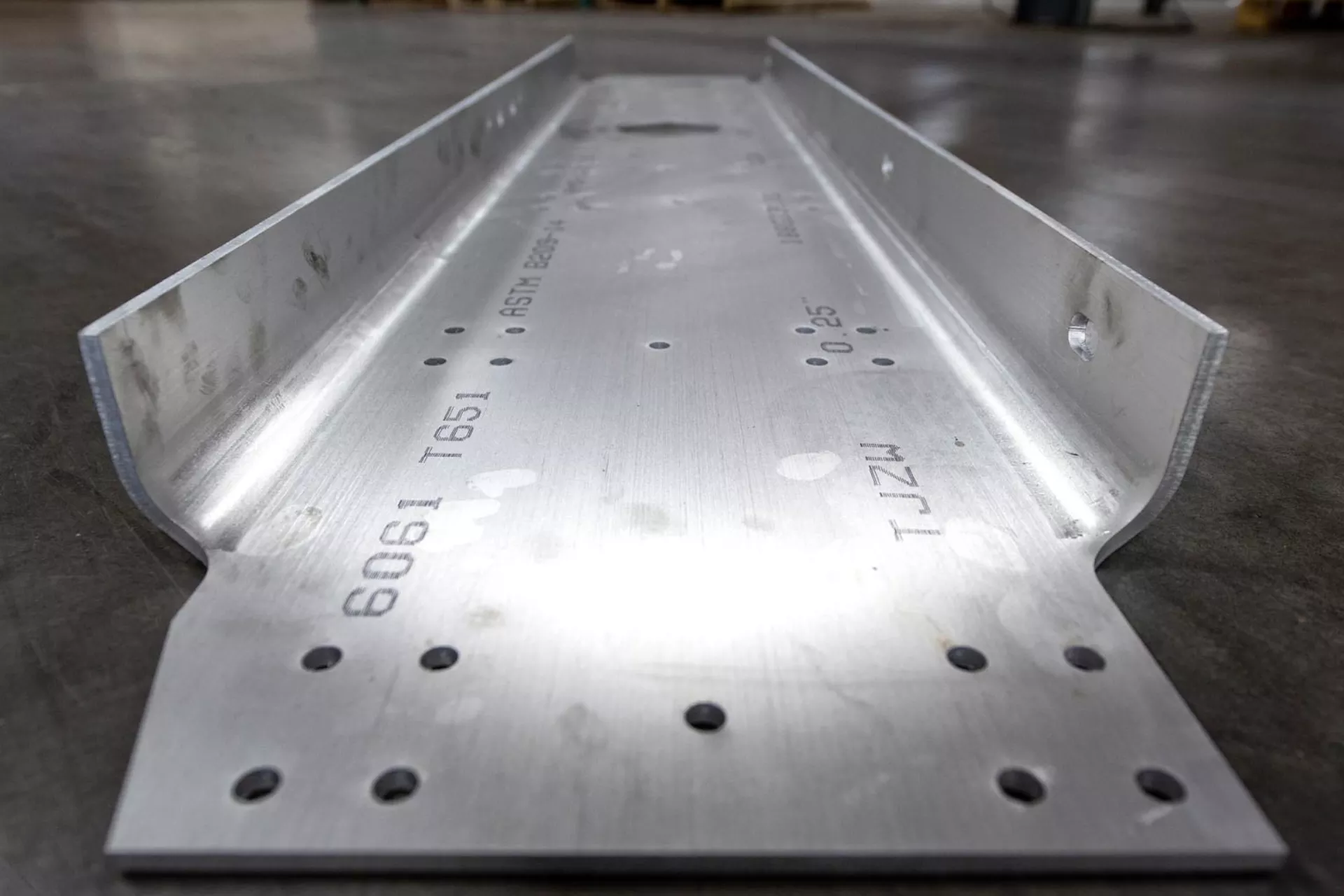

- Cold Rolled Steel (CRS)

- Hot Rolled Steel (HRS)

- Stainless Steel

- Aluminum

- Brass

- Bronze

- Copper

- Polycarbonate

- Lexan

- Anodizing

- Chromate

- Chrome

- Dip Brazing

- Heat Treat

- Nickel

- Paint

- Powder Coat

- Silk Screening

- Zinc

- Custom

- Up to .25 in.

- Up to 8 ft.

- Up to 3 ft.

- Up to 2 ft.

- Up to 75 lbs.

- ± .002 in. (<24”)

- ± .005 in. (>24”)

- ± .002 in. (<1”)

- ± .005 in. (>1”)

- ± 3 minutes

- Coordinate Measuring

- Machine (CMM)

- Grade A Surface Plates

- Final Inspections

- First Article

- Surface

- Hardness

- Statistical Process Control (SPC)

- Quality Control Manual

- Workmanship Standards Manual

- Engineering

- Design

- Assembly

- Kitting

- Specialty Production Shop

- Rapid Prototype

- Low Volume

- High Volume

- 2 to 4 weeks (Standard)

- 4 to 6 weeks (New Parts)

- 1 week (Quick Turn)

- Kanban Programs

- Dock to Stock

- ISO 9001:2008 Certified

- MIL-I-45208A Approved

- MIL-STD-120

- ANSI/NCSL 540-1-1994

- ANSI/ASQC Z1-4-1996

- AutoCAD

- SolidWorks

- Pro/ENGINEER (Pro-E)

- IGES

- STEP

- DWG

- DXF

- Fabricam Fabriwin)

Contact Anpllo for an instant quote

Have A Question About Anpllocnc's Sheet Metal Fabrication Services?

We want you to know that we take pride in every single job that we do, no matter how small or big. We love helping our customers take the designs they have in their head and make them a reality. We’ve been in business so long because of our commitment to our customer service and to our workmanship. Give us a send email today to learn about how our sheet metal fabrication services can help you.

Contact us today to schedule service with one of our professional technicians.

Tolerances

The following table summarizes Anpllo’s production tolerances for sheet metal parts.

| Feature | Tolerance |

|---|---|

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010” (0.254mm) |

Standards

To ensure the manufacturability and accuracy of sheet metal parts, our custom sheet metal fabrication services comply with ISO 2768-m.

| Dimension Detail | Metric Units | Imperial Units |

Edge to edge, single surface | +/- 0.127 mm | +/- 0.005 in. |

Edge to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Hole to hole, single surface | +/- 0.127 mm | +/- 0.005 in. |

Bend to edge / hole, single surface | +/- 0.254 mm | +/- 0.010 in. |

Edge to feature, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Over formed part, multiple surface | +/- 0.762 mm | +/- 0.030 in. |

Bend angle | +/- 1° | |

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify them in your drawing.

Contact Anpllo for an instant quote

Get an Online Sheet Metal Quote

Request an online quote for your sheet metal design by uploading a 3D CAD file. Within a few hours, we'll send you pricing and be available to discuss the design for manufacturing with you.

What Is Sheet Metal Fabrication?

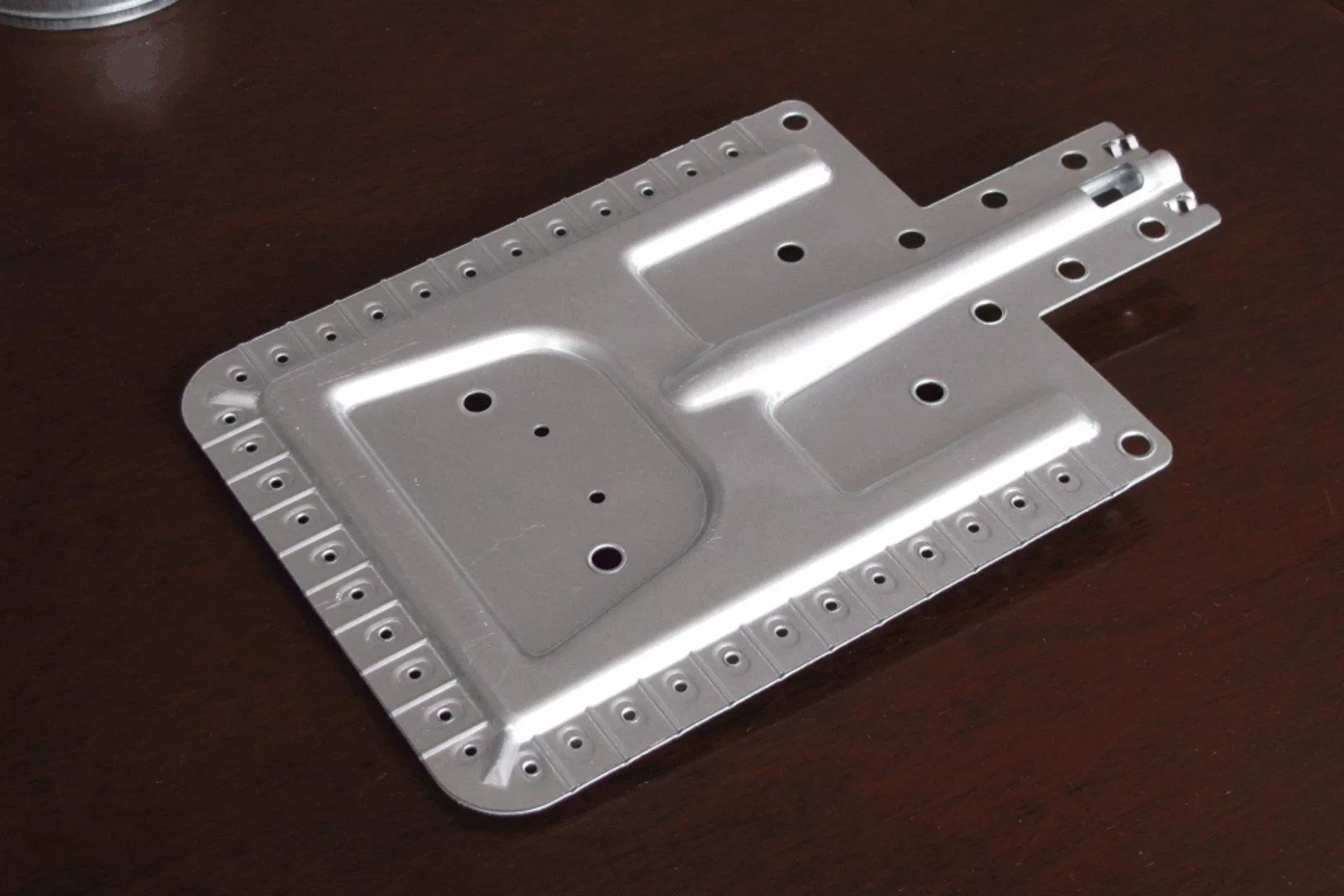

The term ‘sheet metal fabrication’ refers to the numerous manufacturing methods used with sheet metals including laser cutting, bending, welding, and forming. Metal is an extremely versatile material thanks to its ability to be melted down, reformed, manipulated, high strength, high temperature conductivity, electrical conductivity, and its alloying capabilities. Once extracted from ore, metal can be directly formed into different shapes at a foundry including ingots, cylinders, and sheets. Of these, sheet metal is one of the more versatile forms as it is easy to transport, can be directly machined by tools, is suitable for numerous different manufacturing techniques, and is easier to handle. Examples of manufacturing techniques that sheet metal can undergo include stamping, molding, laser cutting, plasma cutting, milling, drilling, cutting, shearing, and bending. Furthermore, constructive techniques, such as welding, can then be used to turn flat sheets of metal into complex 3D shapes, and this sees sheet metals used for all kinds of industries including automotive, aerospace, medical, and consumer electronics. Anpllocnc is a sheet metal fabrication company that can work with sheet metals to fabricate custom parts. Anpllocnc’s mechanical engineers have 20+ years of experience from simple bending to complex precision parts and are proficient in the processing and production of sheet metal parts. Anpllocnc is one of the best sheet metal fabricators in China! We process and manufacture sheet metal according to customer needs. Our sheet metal prototype products have won the favor of customers one after another! Customers who work with us always rave about our sheet metal form products.

What are the advantages of Sheet Metal Fabrication?

| Advantages for Sheet Metal Fabrication | |

| Efficiency and Accuracy | Through the use of the latest CAD/CAM and CNC technology and manufacturing equipment our sheet metal fabrication process is guaranteed to be efficient as well as accurate |

| Durability and Malleability | Sheet metals are strong enough to withstand high pressures, yet they are malleable. They can be formed into almost any shape, which means they are an ideal material for innovative architects and designers to work |

| Diversity Material | Sheet metal is of a low weight and thin gauge making transport and delivery of the product straightforward and cost effective. |

| Easily Repairable | Repairs can be carried out in a simple and straightforward way by removing an individual metal sheet from a structure and replacing it without having to dismantle an entire construction. |

| Low Cost | For all the reasons above – efficiency, durability, ease of transport and design – sheet metal fabrication offers customers a high quality yet inexpensive route to obtaining a product they can work with. |

Contact Anpllo for an instant quote

Metal Fabrication With Quality Sheet Metal

At Anpllocnc, we are committed to providing our customers with high-quality and fairly priced fabrication services. Our lean manufacturing processes minimize waste at each phase of the manufacturing process, allowing us to pass the resulting cost savings directly to our customers.Ready to get started working with Quality Sheet Metal on your next metal fabrication project? Contact our team today.

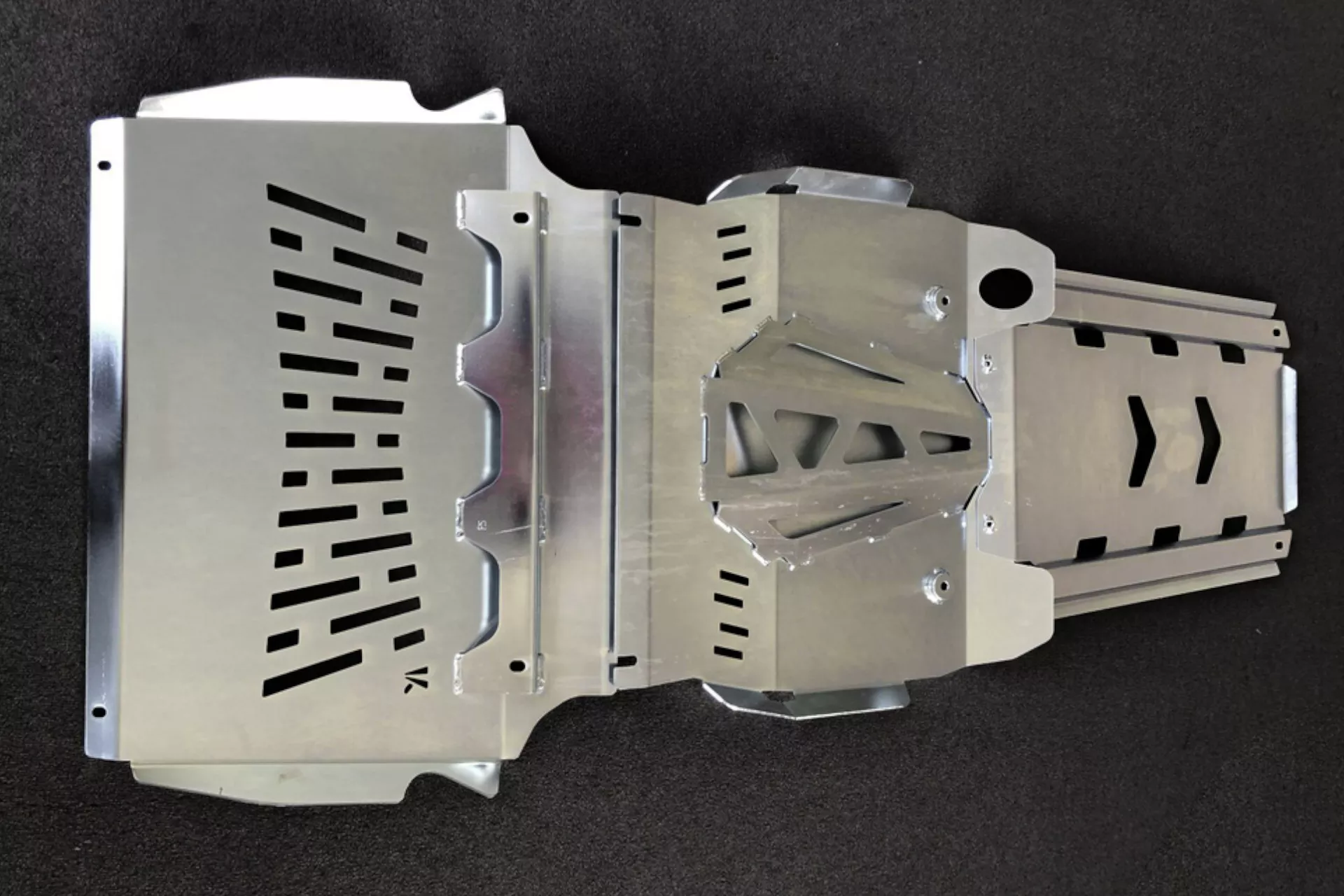

Parts Gallery

Why Choose us?

Complete Equipment

We have the complete equipments. In addition to stamping equipment, other special equipments are also available, such as high precision laser cutting machine, CNC automatic stud welding machine, custom small leveling machine (very important for flatness of panel), laser welding machine.

All the manufacturing process will take over in our plant, this could short the lead time and save your cost.

Quality Management

1, Each process is based on drawings or samples;

2, Follow the ISO9000 quality control path;

3, 100% inspection on costmetic surface parts;

4, Specially reinforced packing to protect the parts from damage in transit

Sign NDA

We signal the NDA with our client in the start stage. Each worker ought to take pre-input corporation education to observe our manufacturing flow, in order that maintain corporation statistics security.

NDA might be signed on board date. As properly as for all our providers should signal NDA. For date security, we use the ISO27001. All the records might be securely saved at our personal community centre.

Our commitment to quality

Anpllocnc is ISO 9001 certified, demonstrating that we are committed to maximizing customer satisfaction and continually examining our own processes to make improvements wherever possible. As a part of our ongoing quality control initiatives, we maintain effective application of documented procedures, while ensuring that we conform to the manufacturing requirements of our customers. This helps us to provide ideal solutions to first-time and repeat customers. While striving to have the best manufacturing processes, we also support our employees through education, training, and a safe work environment.

Industries and Applications

Whether it’s metallic auto parts or electronic device components, Anpllocnc’s sheet metal fabrication has helped businesses in different industries.

Learn More About Our Manufacturing Services

CNC Machining

Rapid Prototyping Services

Choose from CNC machining and sheet metal, get free interactive designs for manufacturing feedback on every quote, and master physical prototypes in days to quickly revise designs during development.

Low-Volume Manufacturing service

Anpllo provides a one-stop service for small-batch production of CNC machining, milling, turning, sheet metal processing, etc.

Frequently Asked Questions

Sheet metal fabrication tolerances refer to the acceptable deviations for features of sheet metal parts required for accurate and consistent installation and integration.

For sheet metal parts, ISO 2768-mk is usually used to ensure proper control of the elements of geometry and size.

Every aspect of a sheet metal fabrication project comes with an associated cost — the design, possible prototype, finishing processes, and others. Asides from the process itself, materials also cost money.

Yes we can custom duct elbows to your specifications. The typical elbow is 3″ 90 degree adjustable galvanized sheet metal. Used in air conditionining and heating for exhaust duct or other ductwork.

The selection of the cutting machine is determined by the gauge of the sheet and the material used, along with other key elements like delivery, tolerances, and geometric complexity as expected. You don’t have to figure out the type of cutting machine suiting your sheet metal as our experts clearly know what kind of equipment, technology, and even materials are best suitable for your project. Thus, just submit your 3D files online and get a professional solution from our experts in fabricating sheet metal quickly.

Generally, the cost of using just a single cutting machine such as a laser cutter to cut a part will spend less than that of multiple forming processes, for instance, cutting, bending, and punching. But most sheet metal parts need to be machined with a combination of different forming processes, and the per-unit costs will reduce by large-volume quantities.

As most sheet metal fabrication processes involve 3D parts, designers should take this into consideration when utilising 2D manufacturing techniques.One such consideration is that metal bends are not square, but slightly rounded. As such, bends will have a radius that will change the distances between the edges as well as leaving a small gap if the part is placed flush against another surface. Furthermore, sheet metal parts have a measurable thickness, and this will affect the size of the bend.Designers who are constructing 3D shapes from 2D laser-cut parts also need to keep in mind where welding joints will be located as access to these areas will be needed during construction. There is no point creating a 3D shape with a small angle between two surfaces that doesn’t permit welding on the inside seam. This also applies to the positioning of bolts and nuts as bends can interfere with access to fittings.Finally, it is essential that designers keep in mind Anpllocnc design constraints such as material thicknesses, laser kerf, and dimensional accuracy. Parts that require tolerances greater than what Anpllocnc can offer or integrate features that are too small cannot be guaranteed.

Sheet metals can be machined into parts using numerous techniques including milling, cons.By far, laser cutting is one of the adaptive machining methods thanks to its use of computer numeric control, the high degree of reliability and accuracy, speed, and operating cost. Furthermore, laser cutters can both engrave and cut in a single machining cycle which helps to speed up production rates while making cut parts market-ready straight out of the machine. However, factors such as laser kerf have to be taken into consideration, and this effectively eliminates laser cutting from being used on thick sheets of metal.Plasma cutters are excellent for cutting thick sheets of metal that do not require levels of precision found in laser cutters. Furthermore, plasma cutting enjoys some of the same benefits as laser cutting including low operating costs and lack of tooling which helps to reduce plasma cut parts. However, plasma cutters are not able to work on non-conductive materials, and the inability to accurately produce small parts makes plasma cutting more ideal for structural parts.Water jet cutters are another low cost cutting option for parts cut from thick metal sheets where accuracy is not essential. Compared to plasma cutters, water jet cutters are excellent for cutting extremely dense materials that are far too difficult for lasers or plasma, and the use of water means that they can cut non-conductive materials. However, the use of water limits what material can be cut (i.e. cannot be used for fabric, wood, and other organics), and then intense pressure of the water can induce mechanical stress.Shearing is by far one of the quickest and cheapest sheet metal cutting techniques around. The use of two sharp right-angled blades that perfectly pass each other can be used to cut long straight lines in a piece of sheet metal, but this is only possible for thin sheets (thick sheets are likely to tear and bend). Furthermore, sheering is only able to cut straight lines from edge to edge, and cannot be used for internal cuts, nor can it be used for curves or other complex shapes.CNC mills are able to produce extremely accurate parts thanks to the use of probing tools, engineered routing bits, and the ability to use vision technologies to measure tools accurately. As such, CNCs are typically used for precision parts where accuracy is essential (such as engine blocks, rotor blades, and matched parts. However, the use of tools and the slow speed of CNCs make them expensive to operate, and are therefore impractical for mass production of low-cost parts. Molds and stamps are another method for producing sheet metal that can be used for mass production. The use of a die allows for such parts to be made with extreme speed and consistency, but the high cost of dies make them unsuitable for prototyping. Furthermore, molds and stamps can wear down over time which sees recurring engineering costs to maintain production quality.Of all the listed manufacturing techniques, laser cutting offers customers one of the best options as it provides an excellent price to quality ratio while also supporting both mass production and prototyping. Laser cut parts from Ponoko can be quickly scaled up from prototype to production without any need for design changes, and the numerous additional services including bending and burnishing allow for market-ready parts to be produced.

Resources

A Complete Guide to Custom Sheet Metal Fabrication

A Complete Guide to Custom Sheet Metal Fabrication Custom sheet...

Read MoreMatters needing attention in the process of sheet metal processing of stainless steel materials

Stainless steel sheet metal processing is an indispensable part of...

Read MoreSheet Metal Fabrication of HVAC Components

Sheet metal Fabrication is a vital processing technology in manufacturing...

Read MorePut your parts into production today.

We have experienced sheet metal fabrication experts. Whether you need laser cutting, sheet metal punching, metal forming, or another service, if it has to do with metal fabrication or manufacturing, we are here to help. Let us know your needs, and we will work with you to find a solution.

You can get in touch with theAnpllocnc using our online contact form. You can email us at [email protected]. We look forward to cooperating with you.