Manufacturing on Demand for the Oil and Gas Industry

From manufacturing parts in high volumes to custom batches, Anpllocnc offers Manufacturing on Demand services for the Oil & Gas industry.Have a small or large project that needs to be delivered under a tight deadline? We can help!

- From prototyping to production

- Huge selection of high-quality materials & finishes

- Get full IP protection and quality documentation

Precision Machining For The Oil & Gas Industry

In the oil and gas industry, components are commonly subjected to harsh operating and environmental conditions. As a result, they must be designed and constructed for durability and reliability to ensure they can withstand use in the industry’s operations.

At Anpllocnc, we provide contract precision machining services to customers across various industries, including the oil and gas industry. With experience and advanced CNC Swiss Machining equipment, we have what it takes to produce high-quality machined parts and products for offshore rigs, drilling equipment, and pipelines. Our components find use in various oil and gas applications, from refinery distribution networks to refined product delivery systems. As new technologies are introduced and adopted, we remain committed to helping customers develop products that drive the industry forward.

Certified For Every Application

Anpllocnc is ISO 9001 certified and our suppliers have industrial certifications.

• ISO 9001

• ISO 14001

• ISO 13458

• ISO TS16949

• AS 9100

Comprehensive Quality Documentation

Get validation reports to ensure the highest quality and compliance.

• CMM Inspection Report

• Full Dimensional Inspections

• Material Test Reports

• Material Certificates

• Certificates of Conformance

• First Article Inspections

Highest Quality Standards

We use a rigorous set of protocols and procedures to maintain quality.

• Special tooling

• Sample size inspection

• Dimensional checks with calibrated equipment

• Review of all quality documentation and industry certifications

• Full IP protections

Machine Tools For The Demanding Thread-Making Process

Anpllocnc has been dedicated to meeting the challenging needs of oil and energy manufacturers. focuses on providing more reliable parts with higher quality Targets.

At Anpllocnc, we offer a wide and diverse range of Customized processing services on demand and material and surface treatment options for oil and energy; our equipment includes horizontal CNC lathes, twin-column machining centers, and turning capabilities. For example, with their high precision and reliability, our horizontal CNC lathes are well suited to the challenges of manufacturing directionally drilled components. Downhole instruments drive increased pressure to produce robust tubing, threads, and telemetry components that can withstand the rigors of surveying and well construction; Anpllocnc machines are ready for the challenge.

Types Of Components Machined For Oil And Gas Applications

Precision machined components find application in various oil and gas equipment. The experts at Anpllocnc design and manufacture parts and products for oil rigs, oilfield drilling systems, gas turbines, steam turbines, downhole hardware, and more. Typical precision machined components we provide include:

- Bushings

- Connectors

- Fasteners

- Washers

- Sealing systems

- Shafts

- Spacers

- Springs

- Vacuum barriers

- Stuffing Box

Manufacturing Capabilities For Oil & Gas Industry

With many years of experience and knowledge in manufacturing products needed for extreme environment applications and our AS9100 certification process, you can rest assured that you will get your parts the way you want them.

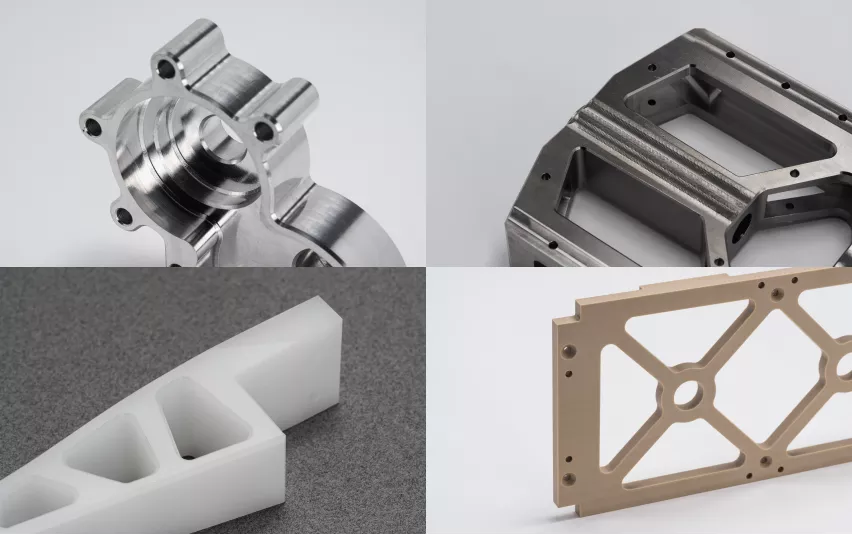

CNC Machining

Milling, turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

Sheet Metal Fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Rapid Prototying

CNC Auto Parts Prototye production

- Wide range of part complexities and sizes

- 1 to 1M parts

Supporting The World's Energy

Stress-Tested, Custom-Designed Products Built for the Oilfield

Oil & Gas is an industry in flux. New, data-driven techniques such as horizontal drilling promise higher precision and greater yields, while advanced sensor technology helps facilitate better safety. The innovation in this space is amazing — especially if you work with the right strategic partner.

Materials & Surface Finishes For Oil & Gas Parts

We can offer a wide range of material and finish options for prototyping to full production.

Oil & Gas Industry Parts materials

Select from a broad range of durable & pristine materials

Aluminum: 5052, 6061-T6, 7075-T6, 2024-T351

Copper: Copper C110, Copper C101

Thermoplastics: Polycarbonate (PC), Polyoxymethylene (POM), PEEK, ABS

Commodity polymers: Polypropylene(PP), PVC, Polyethylene (PE)

Composites: Garolite G-10, FR4

Oil & Gas Industry Parts Surface Finishes

Select from these finishes to protect your parts:

- Anodizing

- Powder coating

- Electroless nickel plating

- Insert installation

- Heat treatment

- Passivization

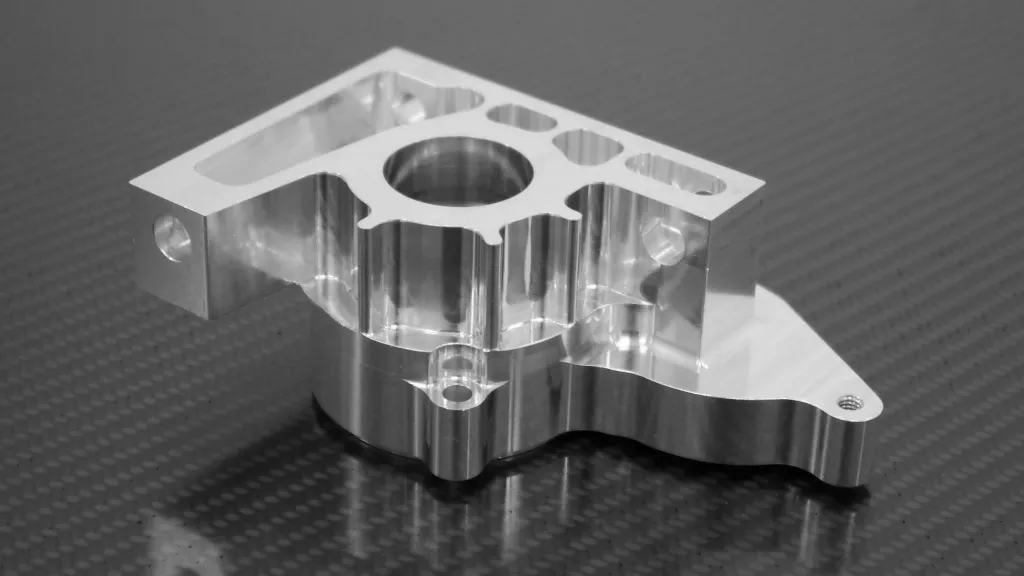

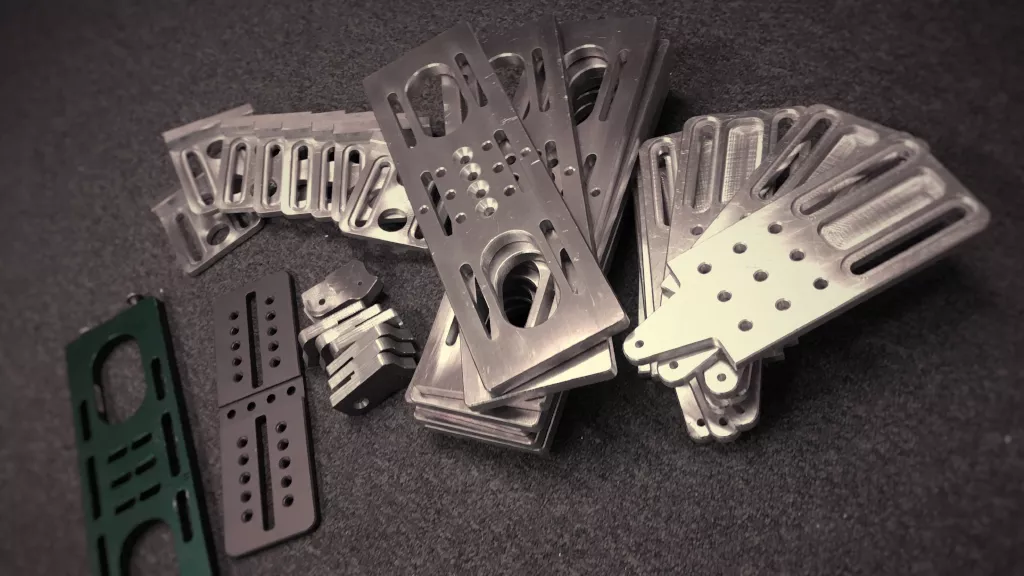

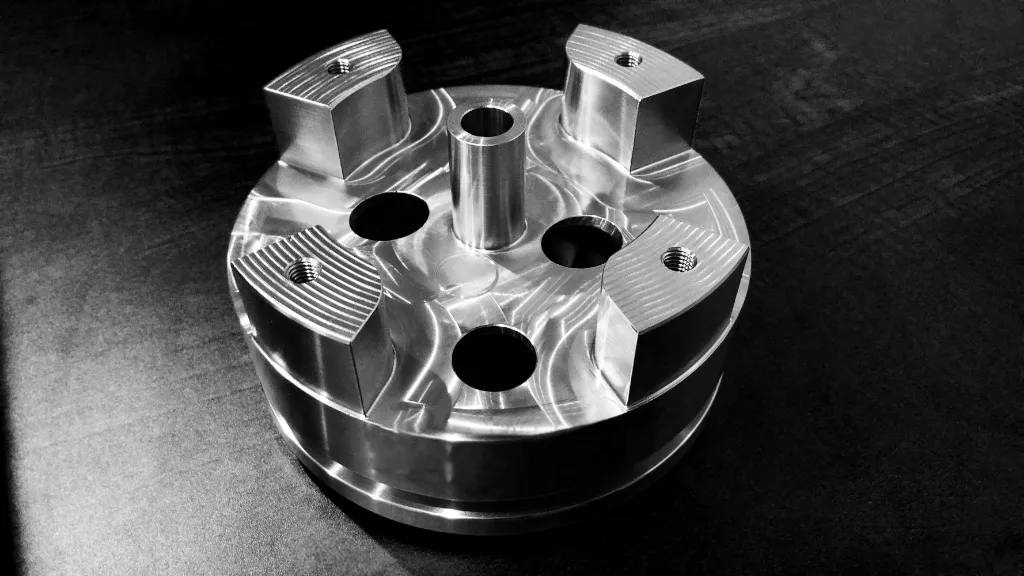

Gallery Of Oil & Gas Industry Parts

Stability Amidst Volatility

Many onshore and offshore companies operating in this sector face problems related to component failure and related downtimes. Often these downtimes mean money, labor, and time losses. We provide just-in-time (JIT) assembly and delivery services to avoid this. This helps us assure minimal downtimes and maximum uptime for most clients.

Our well-equipped manufacturing facility and engineering expertise spanning over decades allow us to assure the fastest turnaround times in the industry. Our experts work with clients through all phases of ordering, making us one of the country’s most popular oil and gas Customized processing services on-demand providers. At Anpllocnc, everything from conceptualization to manufacturing to delivery is performed in-house by industry experts, allowing us to stay true to our commitment to quality. Please contact our team today via email at [email protected] for more information on our oil and gas Customized processing services on demand.

How Anpllo Helps Oil & Gas Companies

With process advantages such as speed, automation, and repeatability, on-demand custom machining services for oil and gas industry parts have become an important source of supplemental equipment parts.

Advanced Processes Solve Complex Geometries

Our fabrications can achieve incredible geometric complexity. No matter your design’s complexity, we can produce any product with superior mechanical and cosmetic properties. Our capabilities include CNC technology, including 5-axis machines, to easily produce rapid prototypes and low-volume production parts.

To Spec And On Time, Every Time

We adhere to comprehensive quality control processes and protocols to keep your supply chain consistent and robust. When we cooperate with you, the drawings must go through a complete review process. Quality manufacturing engineers often review and revise with you to ensure the processed parts meet your standards. Our quality inspection team conducts a thorough inspection of the parts produced to functional and cosmetic specifications, and we handle all customs clearance requirements and ensure on-time delivery.

Customization At Any Scale

Thanks to our specialized cutting-edge manufacturing capabilities, we can offer customization options from single functional prototypes to more parts reaching the end customer. We have talented engineers in-house who can speed up your innovation process and tweak designs to make 3D printers and CNC machines look and function better, even if each component is unique.

Need Parts To Be Machined?We Can Assist

Whether it’s a single component or a batch of parts, we will precision machine it to perfection. Contact us to receive a quote!