Plastic Materials

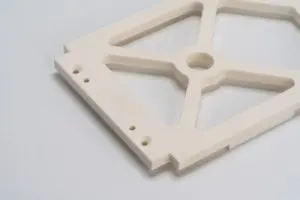

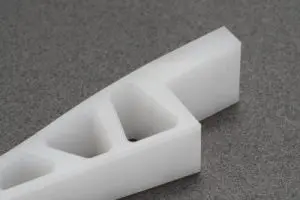

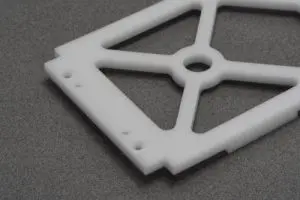

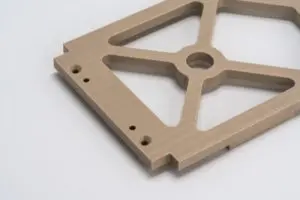

Anpllocnc is a high quality production shop with expertise in aggressive machining while optimizing parts with extremely tight tolerances. Plastic Materials we have extensive experience machining have characteristics that necessitate appropriate speeds, feeds, tooling, and manufacturing processes to be productive and cost effective.

Plastic materials used in Anpllocnc CNC machining

At Anpllocnc, we understand that the quality and grade of plastic that is used for machining are equally important as the technique. We are capable of working with a wide range of superior grade plastics. This capability makes us the “one-stop-solution” for our customers’ needs.

The plastic material of small as well as large micron range can be machined effectively at our state-of-the-art facility. Let us have a look at the wide range of plastic materials that we can machine:

| Name | Description | |||

| POM (Delrin/Acetal) | High stiffness, high accuracy, low friction, easy to machine. | Browse POM (Delrin/Acetal) materials | Get instant quote |

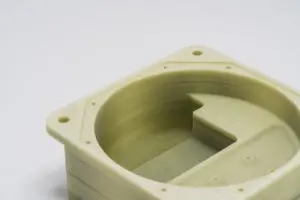

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. | Browse Nylon materials | Get instant quote |

| ABS | Common thermoplastic, impact resistant, easy to machine. | Browse ABS materials | Get instant quote |

| PEEK | High-performance thermoplastic, very high strength, thermal and chemical resistant. | Browse PEEK materials | Get instant quote |

| PTFE (Teflon) | Low friction, chemical and thermal resistant. | Browse PTFE (Teflon) materials | Get instant quote |

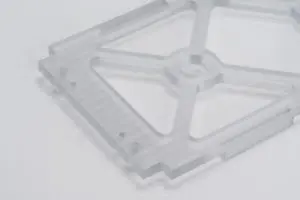

| Polycarbonate | High toughness, excellent impact strength, transparent. | Browse Polycarbonate materials | Get instant quote |

| Polyethylene | Excellent strength-to-weight ratio, impact and weather resistant. | Browse Polyethylene materials | Get instant quote |

| PVC | Excellent chemical and weather resistance and good toughness. | Browse PVC materials | Get instant quote |

| PMMA (Acrylic) | Transparent rigid plastic often used as a substitute for glass. | Browse PMMA (Acrylic) materials | Get instant quote |

| PET | Tough plastic that offers excellent wear resistance and mechanical strength. | Browse PET materials | Get instant quote |

| Polypropylene | Excellent chemical resistance. Food-safe grades available. | Browse Polypropylene materials | Get instant quote |

| G-10 | High strength, low moisture absorption, and high level of electrical insulation and chemical resistance. | Browse G-10 materials | Get instant quote |

| FR4 | Flame retardant glass fiber epoxy laminate. | Browse FR4 materials | Get instant quote |

CNC metal Machining

Mental material for CNC machine processing, the main materials are iron, aluminum, copper, titanium, alloy steel, aluminum alloy, etc., and the processing technology mainly includes turning, milling, grinding, boring, and composite processing.

Finishing Services for CNC Machined Parts

Our CNC machine shop in China offers various finishing options for your machined parts. If you cannot find the finish option you are looking for below, please get in touch with us directly.

Anpllocnc plastics CNC Machining Services

Plastics CNC Machining service

5-15 day lead time

Get your parts CNC machined in metals and plastics

Custom Plastics CNC Milling Services

CNC milled prototypes and production parts in days

Plastics CNC Turning Service

CNC turned prototypes and production parts in days

Plastics Sheet Metal Fabrication Service

Sheet Metal Fabrication Service and production parts in days

Plastics Rapid Prototyping Services

Rapid Plastics prototyping and CNC production of Plastics parts in days.

Plastics Low Volume Manufacturing Service

Plastics low-volume fabrication services and production parts can be completed in a matter of days

Frequently asked questions

Plastic machining is a manufacturing process that involves cutting unwanted geometry from a raw block of plastic, bit by bit with a computer numerically controlled (CNC) milling tool, very precisely and allows complex parts to be produced with great accuracy.

The cost of plastic CNC machining depends on the complexity and size of the part as well as the type of plastic that is used. These variables will influence the type of machine that is required, the time it takes to produce the part, and the cost of the raw material.

Send File: Get an instant CNC machining quote.

ABS is a great general-purpose plastic for CNC machining as it has good machinability and dimensional stability. For applications that require low friction and high stiffness, POM is a viable option. Other plastics can be good choices for applications that have more particular requirements such as specific mechanical or aesthetic properties.