CNC machining materials

Invar CNC Machining

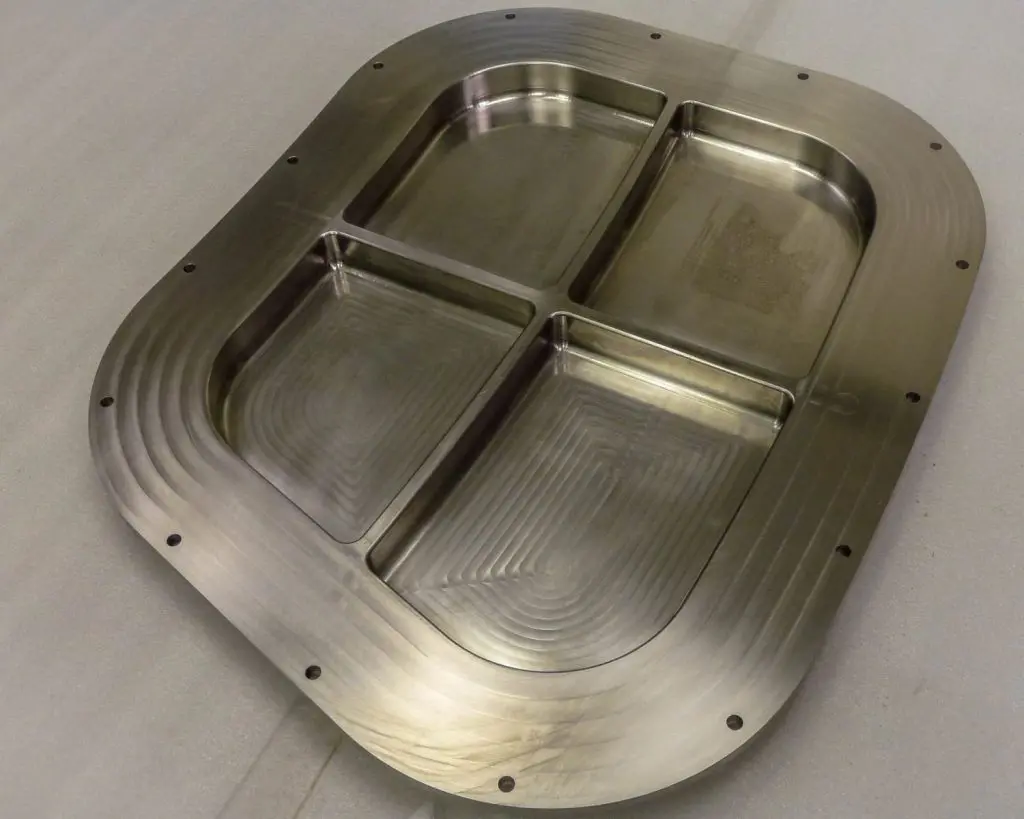

Anpllocnc specializes in machining Invar parts and assemblies using state-of-the-art CNC turning, milling, and 5-axis centers. Years of experience provide expert knowledge of Invar characteristics and how this material group reacts when machined. Tool selection, cutting pass depths, mill/lathe feed and speed, chip control, and high-pressure coolant are critical in controlling heat generation, which can cause part movement and tool deflection during the machining process. This level of skill ensures world-class precision machining that meets or exceeds the most demanding tolerances. The innovative Anpllocnc team is always available to review and guide you during the design process. Our goal is 100% customer satisfaction, providing AS 9100/ISO 9001:2015 certified quality machining resulting in timely turnaround and on-time delivery.

Difficulties surrounding Invar and CNC machining

Invar 36, Super Invar 32-5 and Kovar would be classified as exotic alloys, both for their rareness and price. As a buyer you need a shop with experience machining these alloys and understands the challenges associated. At Anpllocnc we have been steadily honing our skills to produce highly complicated parts out of these materials. Invar 36 has a high cast iron content and is at risk for flash rusting. The solution is typically nickel plating. The nickel bonds well with the nickel in the alloy and produces a rust resistant coating. The challenge here is the threads cannot be left uncoated because they can rust or seize a bolt in the part. So, you need to over size the threads by a specific amount to ensure the thread profile is in spec after plating is complete. Here at Anpllocnc we have mastered the process for CNC machining Invar.

| Processes | Lead Time | Finishing Options | Tolerance |

| CNC Mill CNC Lathe | As fast as 7 days | Vibratory Tumbling, Media Blasting, Powdercoating | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

About the Invar Material

Invar alloy (UNS K93600), a 36% nickel-iron alloy known for its unique low expansion properties. The name Invar comes from the word invariable, referring to its relative lack of expansion or contraction with temperature changes. Invar alloy has a rate of thermal expansion approximately one tenth that of carbon steel at temperatures up to 400 oF (204 oC). Invar, a low expansion alloy, possesses the lowest thermal expansion rate among all metals and alloys from room temperature to 230 degrees Celsius.

Invar alloy proves to be an asset being ductile, having welding ability and machining properties like stainless steel. It does not expand nor contract over a wide range of temperatures. This metal alloy is unaffected by stress corrosion and cracking.This characteristic makes the alloy a candidate for a growing number of applications where dimensional changes due to temperature variation must be minimized and also in conjunction with high expansion alloys in applications where motion is desired when the temperature changes. Invar Alloy has been the metal of choice for low expansion applications for years. “Super-Invar” (31% NI-5% Co-Balance Iron) has found some favor because it has a near zero coefficient of thermal expansion over a limited temperature range. The useful range of Super Invar is limited to between -32° to + 275°C. because the material begins to transform from Austenite to Martinsite at temperature below-32°F

Invar is used where high dimensional stability is required, such as precision instruments, clocks, seismic creep gauges, television shadow-mask frames, valves in engines, and antimagnetic watches. In land surveying, when first-order (high-precision) elevation leveling is to be performed, the level staff used is made of Invar, instead of wood, fiberglass, or other metals. Invar struts were used in some pistons to limit their thermal expansion inside their cylinders. Machining Invar alloy is available in two variations. One is the conventional Invar alloy, used generally for its optimum low expansion properties. The second is a variation of the basic alloy known as Free-Cut Invar “36”® alloy (UNS K93050 and ASTM F1684). This alloy has shown improved machinability for applications where high productivity is important. It is also a 36% nickel-iron alloy, but with a small addition of selenium (Fig. 1) to enhance machinability.

Invar Industry Applications

Invar can be used in a variety of applications within the aerospace, medical, and consumer electronics industries. But where superalloys with low CTE are really starting to outperform other metals is in technologies within the automotive industry. As autonomous vehicles rise in popularity, sensors, radars, and cameras become increasingly advanced and critical to the function of the car. LiDAR, an acronym for light detection and ranging, uses light waves from a laser to calculate how long it takes for the light to hit an object or surface and reflect back to the scanner—determining the distance of surrounding objects. An alloy with near constant dimensions and long-term dimensional stability, such as Invar 36, is extremely important in such intricate devices. Alternative alloys, like Kovar, with low CTE are also viable options for casting LiDAR sensors. Investment casting is a cost-effective solution compared to machining LiDAR parts from solid.

Anpllocnc Advanced Invar Machining Services For Your Industry

Anpllocnc utilizes advanced CNC technology and machining equipment to offer ultra-precision Invar machining services. Our Invar machining capabilities enable us to machine Invar parts with tight tolerances and complex geometries, making us the go-to partner for various industries.

Invar Material Properties

Invar 36

| Yield Strength (tensile) | Elongation at Break | Hardness | Density |

| 40,000 PSI | 30% | Rockwell B90 | 8.05 g/cm^3 0.29lb / in^3 |

Invar Material Finish

Invae 36 is very similar to most grades of steels/stainless steel in terms of overall appearance. Invar can be media blasted or tumbled to achieve a multitude of surface finishes. Additionally, powder coating can be applied to achieve more matte/glossy colors.

Invar Design Recommendations

| Min Wall Thickness | Min End Mill Size | Min Drill Size | Max Part Size | Undercuts | Radii : Depth |

| 0.5 mm (0.02 in) | 0.8 mm (0.03 in) | 0.5 mm (0.02 in) | 1200 x 500 x 152 mm [x,y,z] (mill) 152 x 394 mm [d,h] (lathe) | Square profile, full radius, dovetail profiles | Depth must not exceed 12x drill bit diameter. For end mills, depth must not exceed 10x tool diameter. |

Get your Invar parts into production today

Anpllocnc is a trusted name when it comes to providing advanced invar machining services. With CNC technology and state-of-the-art equipment, we can perform complex machining operations for many different CNC machining materials including invar. Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision parts with the tightest tolerances. We can achieve tolerances as tight as 0.0005″.