Injection Molding Service

At Anpllocnc, we recognize that each customer that comes to us for injection molding is unique and has individual needs and goals. That’s why we are happy to offer custom components and molds. Because we’re not just an injection molding company. We’re problem solvers.From concept to finished product, we’re with you every step of the way.

- No minimum order quantities

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certified

- 24/7 engineering support

Anpllocnc Plastic Injection Molding Service:Manufacture Low Cost, High-Quality Parts in Volume

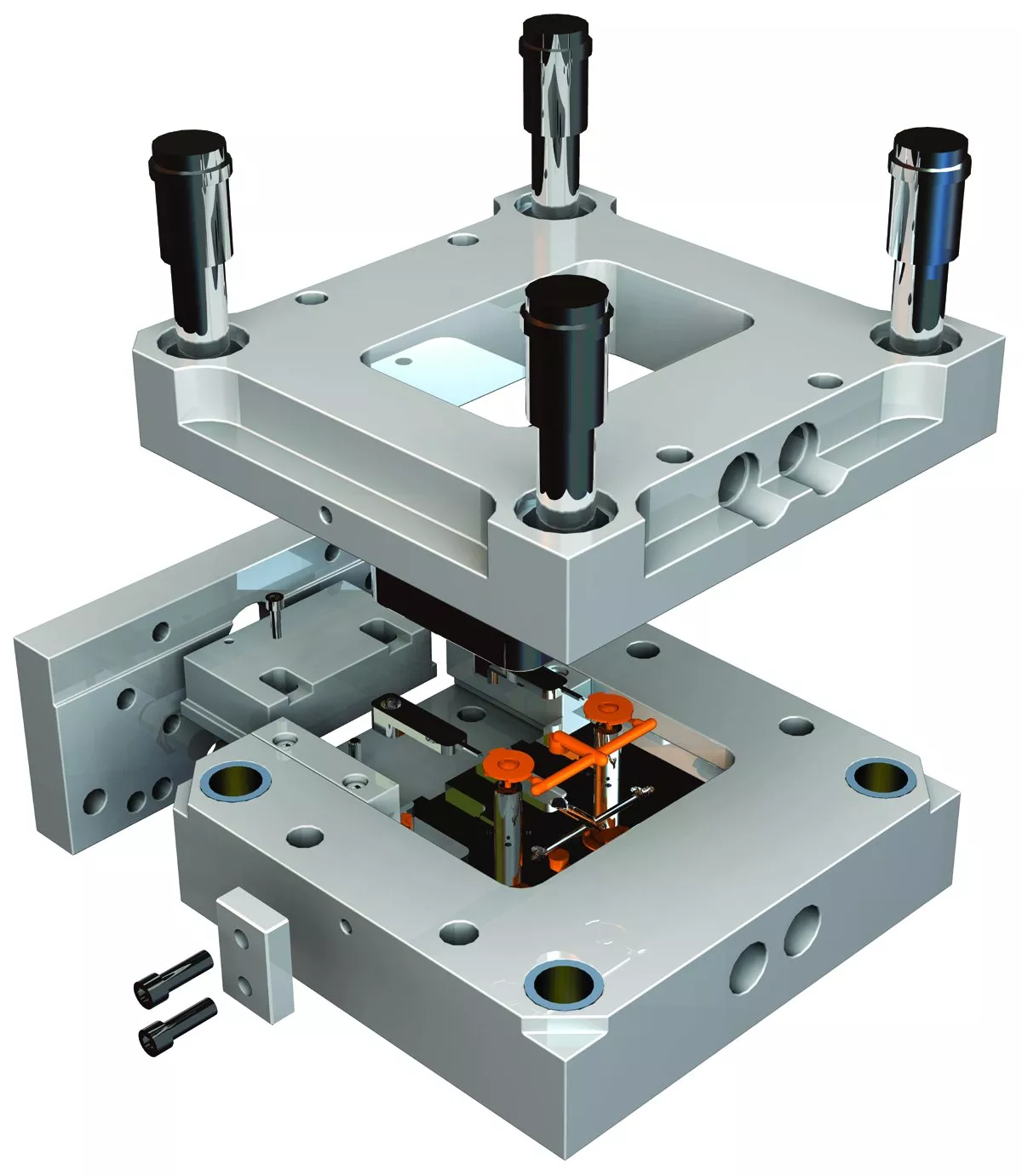

Anpllocnc is a trusted manufacturer that is dedicated to seeing you and your product succeed. We offer a complete suite of in-house manufacturing and engineering services dedicated to molding, tooling, project engineering (DFM-Design for Manufacturing), & production management (including tooling, process, and mold validation).

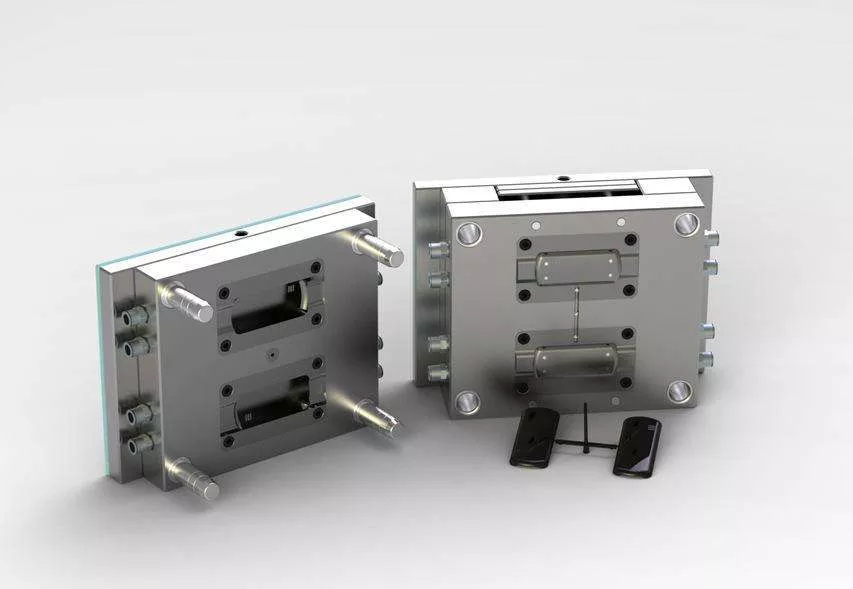

Anpllocnc offers complete in-house tooling solutions that produce high-quality & cost effective parts. We’re experts in building new molds specifically for your project and maintaining and revising existing molds, tools, and fixtures.

Anpllocnc clients benefit from a collective depth of engineering knowledge, expertise, and perspectives on manufacturing challenges not available elsewhere. From unique tooling solutions that reduce capital outlays to material options that enhance performance while decreasing cost of goods, Anpllocnc is equipped to find solutions tailored to a project’s specific needs while saving on manufacturing costs.

From Concept To Completion

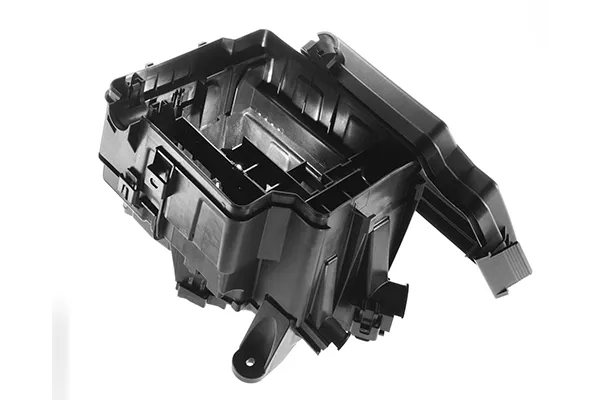

Whether you’re using plastic injection molding to manufacture medical devices more efficiently, prevent contamination of apparel products or reduce the weight of car parts and components, Anpllocnc has the experience, expertise and craftsmanship to ensure the success of your project.

Guiding customers through every stage of a project, our comprehensive approach includes advanced design and engineering assistance, mold making, prototyping, real-world testing and automated assembly services.

Purpose-Driven Innovation

At Anpllocnc, we believe in harnessing the power of process to drive innovation. Our proprietary i6 Innovation Process leverages market insights with advanced technical expertise to fully imagine, test, produce and deliver 360-degree solutions. While innovation involves creativity, free-thinking and imagination, the i6 Innovation process gives it direction, power and purpose. Adhering to this disciplined approach is vital to helping solve problems and consistently deliver repeatable, scalable plastic injection molding services for our customers.

Types Of Injection Molding

Rapid Tooling

Rapid Tooling is a fast and cost-effective process to create aluminum or steel injection molds for quick-turn injection molding. It decreases the time and cost of the product.

Overmolding

Overmolding is a unique injection molding process that combines two or more components together.High Quality Process for Pilot Runs, Low-Volume Production, and Bridge Tooling

Insert Molding

Insert molding involves placing an insert or substrate into the mold cavity before injecting it with molten plastic. The insert can be made of metal or any other material that can withstand the temperature and pressure.

Silicone Rubber Injection Molding

Silicone rubber injection molding is a fast way to make elastic, soft, durable parts within two weeks. Ideal for food, medical, seal ring, functional prototypes, and low-volume production.

Our Work & Capabilities

At Anpllocnc, we’ve provided plastic injection molding services for a diverse range of industries. We are one of very few plastic injection molding companies in the world that uniquely specializes in engineered resin injection molding products. In addition as needed, we use 3, 4, and 5 axis machining technology in order to complete .0001” tolerances. Check out our previous work and get to know our talented team of engineers and specialists who help broaden and advance our capabilities.

- Contract Manufacturing

- Product End Item

- Product Sub-Assembly

- Packaging

- Custom Tool Design

- Production Molding

- Prototyping

- Cleanroom Molding

- Micro-Molding

- Over-Molding

- Mold Design & Construction

- Production & Prototype Molding

- High / Low Volumes R&D Testing

- Production & Prototype Sampling

- Miniature

- Small Parts

- Medium Parts

- Large Parts

- Multi-Component

- Injection

- Insert

- Over Molding

- HIPS – High-Impact Polystyrene

- ABS – Acrylonitrile Butadiene Styrene

- PP – Polypropylene

- TPU – Thermoplastic Urethane

- PETG – Polyethylene Terephthalate

- PC – Polycarbonate

- Luran

- Laminated Plastic

- Nylon

- Lexan

- Plateable Plastic

- Polypropylene

- Noryl

- Acetal

- Delrin

- Santopreme

- Valox

- Kraton

- Rilsan

- FDA Approved

- Chemical Resistant

- Glass Filled

- Heat Resistant

- High Impact

- High Viscosity

- Mineral Filled

- Talc Filled

- Carbon Filled

- Weather Resistant

- UL Rated

- Thin Walled

- Custom

- ISO 13485:2003 & 9001:2015

- FDA Registration no. 3000284443

- cGMP Compliant

- Class 100,000 (8) Cleanroom

- Min:30 tons

- Max:3000 tons

- Min:3 oz

- Max:600 oz

- Min:1 cavities

- Max:64 cavities

- +/- .0001

- +/- .001

- Visual Inspection

- CMM Dimensional Inspection

- Design Engineering

- R&D Engineering

- DOE

- Engineering Trial Runs

- Validation Runs

- IO, OQ, PQ

- Prototyping

- Tooling Production & Prototype

- Product End-Item Assembly

- Product Sub-Assembly

- Video-Based Measurement Systems

- Optical Comparator

- Force Tester

- Statistical Software

- Quantitative and Non-Quantitative Tools

- Biological & Environmental Monitoring

- Precision Hand-Held Instrumentation

- Pin Gauges

- Extended Capabilities Via Certified Analysis and Testing Facilities

- Sterilization Prepping and Configuration

- Silk Screening

- Pad Printing

- Laser Marking

- Prototype Tooling/Molds 6-8 weeks

- Production Tooling/Molds 6-14 weeks

- Mold test for First Article parts 2-3 weeks

- Production molded parts 2-3 weeks

- First Article Inspection – 1 week

- Expedite Services Available

- Minimum – 100 Units

- Maximum – 25 to 50 Million Units

- Pre-Production

- Pilot Production

- Prototype

- Low Volume

- High Volume

Custom Products

Contact Anpllocnc

Best In Class Engineering From Anpllocnc

Anpllocnc is committed to manufacturing the highest-quality products. We are ISO 9001:2015 certified quality management system and ISO 13485:2016 certified quality management system. Our rigorous attention to quality means we have an external defect rate of only 17 ppm. This rate exceeds every industry benchmark for performance.

We collaborate closely with customers, from concept development through prototyping through high-volume production. Our customers know that we strictly honor our schedule commitments.

For more information about our specialty plastic injection molding services or to obtain a personalized quote, please contact us. We can’t wait to show you what we can do.

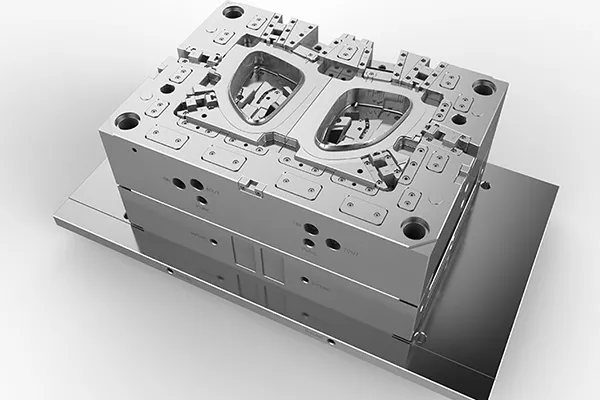

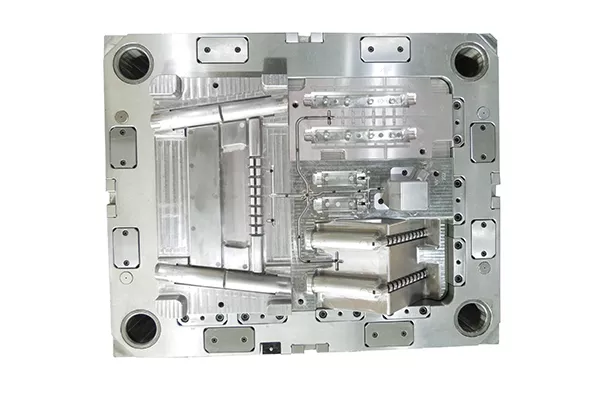

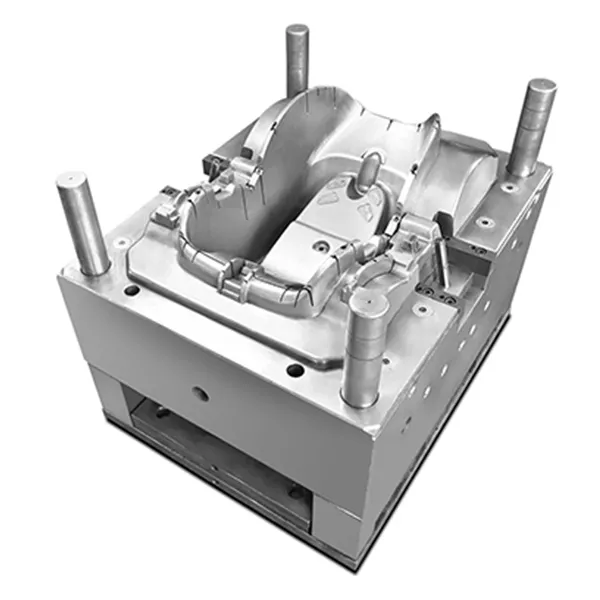

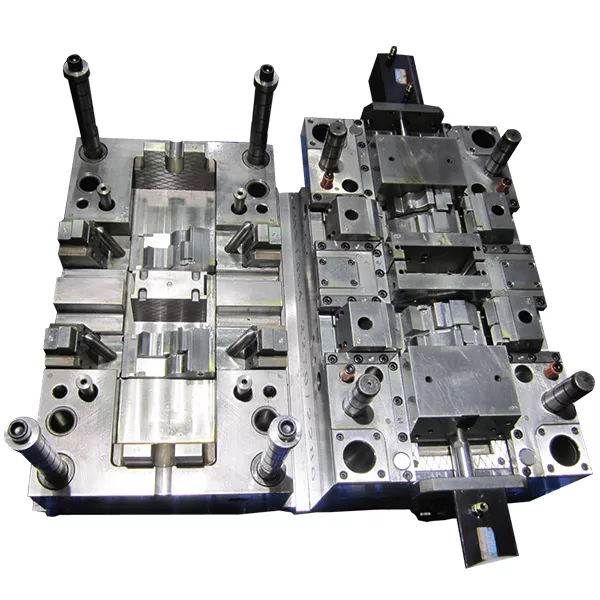

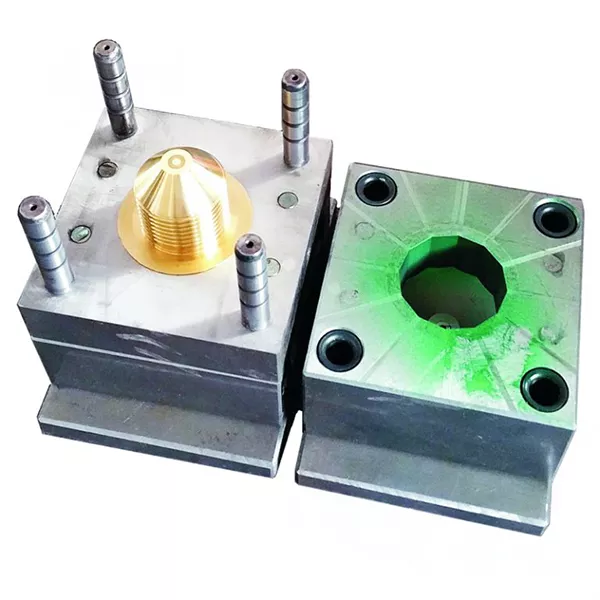

Mold Services

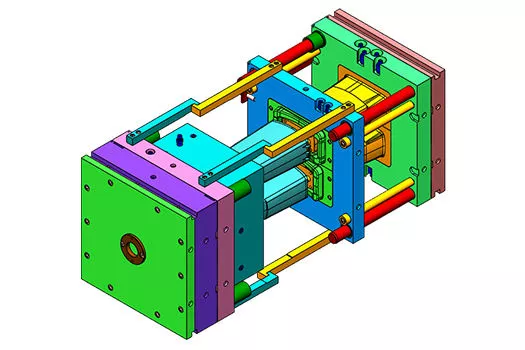

Anpllocnc builds a diverse assortment of molds, from small, single-cavity prototypes to 64-cavity, high-production molds. From design to delivery, Anpllocnc can help make your next big idea a reality. Our in-house team of technical designers and engineers can design, provide prototype parts, build molds and run production. We can begin immediate production on parts with your existing tooling or turn your concept into a real product. We offer bulk distribution and individual order fulfillment.

For Diy & Low Volume

Rapid Mold

Rapid prototype tooling uses aluminum inserts to make the tool. This method is only for small quantities up to 10,000 pieces, providing design flexibility, reducing the mold cost and cut down lead-time to around 1-2 weeks.

For Lowest Per Part Cost

Prodution Mold

- Lead Time – 3 Days

- Visually Appealing Surface Finish

- Instant Quotation Available

- A.K.A Stereolithography 3D Printing

For Lowest Per Mold Cost

Family Mold

Family molds reduce tooling costs by combining similar designs into one single mold. This process is ideal for >10,000 prototypes of various shapes by leveraging the manufacturing efficiency of molding with the flexibility of custom tooling

For Complex Parts

Multi Cavity Mold

Best for high-volume, repeatable parts, multi-cavity molds contain identical cavities to increase throughput and achieve a lower favorable per-unit cost.

Mold Products

We Manufacture Different Types Of Molds For Our Customers

Injection Molding Company

Why Choose US?

Design & Engineering

In-house design and engineering with professional guidance through every step of the process.

Molds & Tooling

Our mold makers have years of experience with custom plastic injection molds and tooling.

Injection Molding

Quality-controlled production, experts in a wide variety of capabilities, materials, and sizes.

Quality Control

Quality assurance is an integral part of any company in today’s competitive marketplace, and we take it very seriously. QA at Anpllo is a three-step process:

- A visual inspection is performed by our trained machine operators on every part that is made the moment it comes out of our machine using the parameters and critical dimensions set by you, our customer, to identify any rejects.

- The injection molded parts are then randomly inspected once again by our QA personnel at the machine once every hour, and any rejects are logged.

- Finally, the acceptable parts are boxed, counted, and moved to our quality control department, where they are randomly inspected once again, and the count is verified. The injection molded parts are then ready for shipment.

Advantages Of Injection Molding

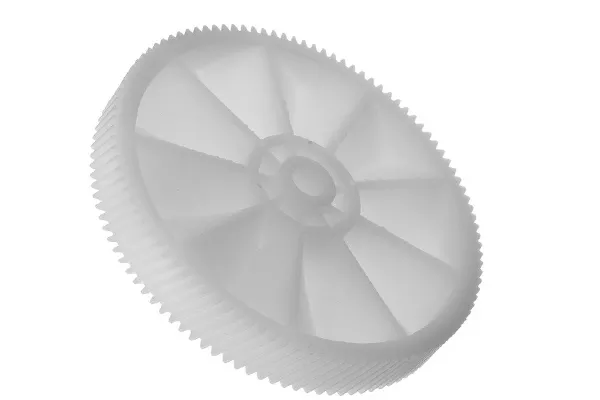

Plastic Injection Molding is the most common manufacturing method to produce plastic parts in commercial and industrial use. It is widely applied for industries like medical devices, housing appliance, mobile devices, equipments and instruments,etc. There are many advantages using our Anpllocnc plastic injection molding service.

- A wide range of plastic materials available

- Various of good quality post finishing and colors available

- Once tool is built, molding parts quickly at very low cost

- High repeatability with consistent quality

- Detailed DFM (design for manufacturing) provided

- Customized tool lifetime depending on your demand

- No MOQ (Minimum Order Quantity) limitation

- Mold Flow Analysis can be provided upon request

Other Manufacturing Services

Vacuum Casting

A.K.A Urethane Casting is quick & cost effective process to make 20-100 production level parts.

- Silicone Molding

- Lead Time 10 Days

- Captures Fine Details

- 100+ Materials Available

Anpllocnc’s Laser Cutting and Laser Engraving service delivers parts in 48 hours or less.

- Sheet Metal Cutting

- Acrylic Laser Cutting

- PCB Laser Cutting

CNC Machining

Get access to low-cost, high-quality custom CNC machining service for complex designs

- Over 700 CNC Machines

- Complete CNC Turning

- Full 3-axis CNC Milling

- 5-axis CNC Machining

3D Printing

Prototype to Production with over 7 different 3D printing methods such as:

- FDM, SLA, SLS

- MJF, DMLS, Polyjet

- Lead Time 2 Days

- 100+ Materials Available

Applications For Plastic Injection Molding

Injection Molding Resources

Learn more about Plastic Part Production

No posts found!

Contact Anpllocnc

Industry-Leading Custom Plastic Injection Molding Services From Anpllocnc

When businesses need custom plastic injection molding at globally competitive prices, they know they need to look no further than The Anpllo Group. We provide a host of services to meet the most complex projects. Our ISO 9001:2015 certified manufacturing facility is located in China and operates 24 hours a day, seven days a week, running 125 presses.

By reshoring, we not only support China-made products, but we provide exceptional quality while minimizing the effects on the environment through a reduced carbon footprint. Bringing jobs back home also offers numerous other benefits, including shorter lead times and lower delivery costs. Contact us for more information on our services or submit a quote request today.