Manufacturing on Demand for the Military and Defense Industry

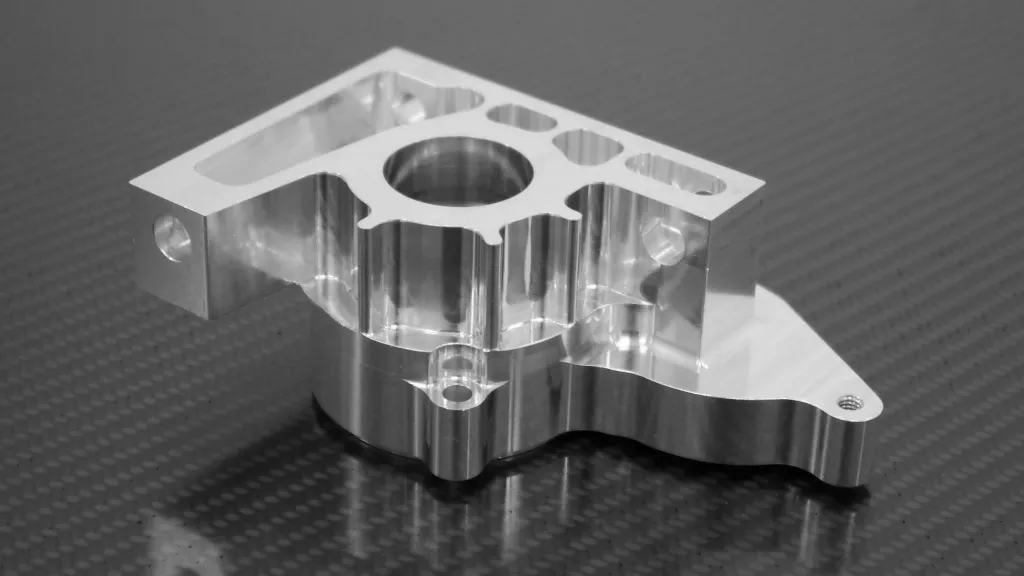

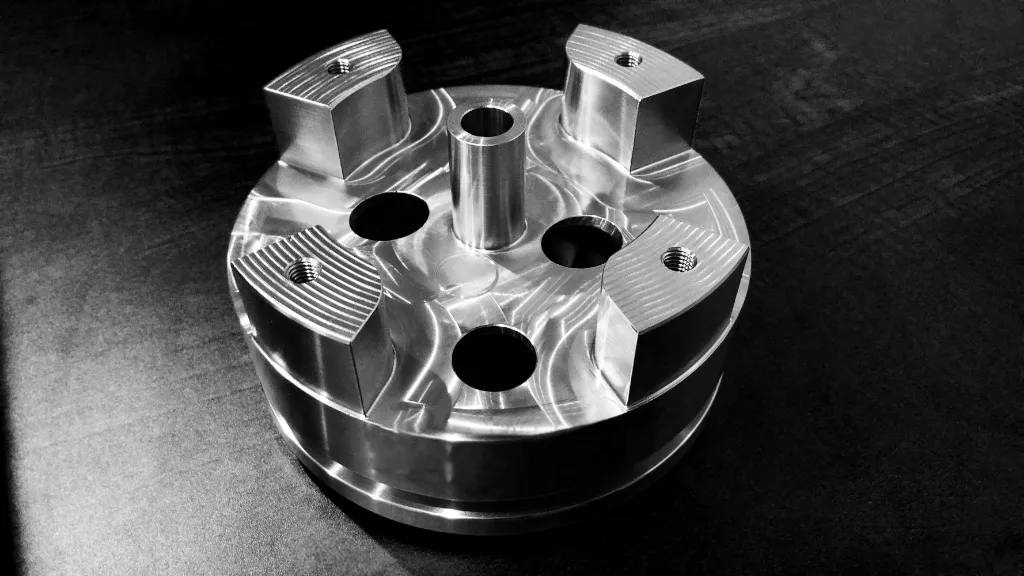

Anpllocnc specializes in precision parts and components that match military standards. We can provide complex machined parts at close tolerances along with accurate supporting documentation.

- Network of AS 9100 certified manufacturing partners

- Tight tolerances & complex geometries

- Get full IP protection and quality documentation

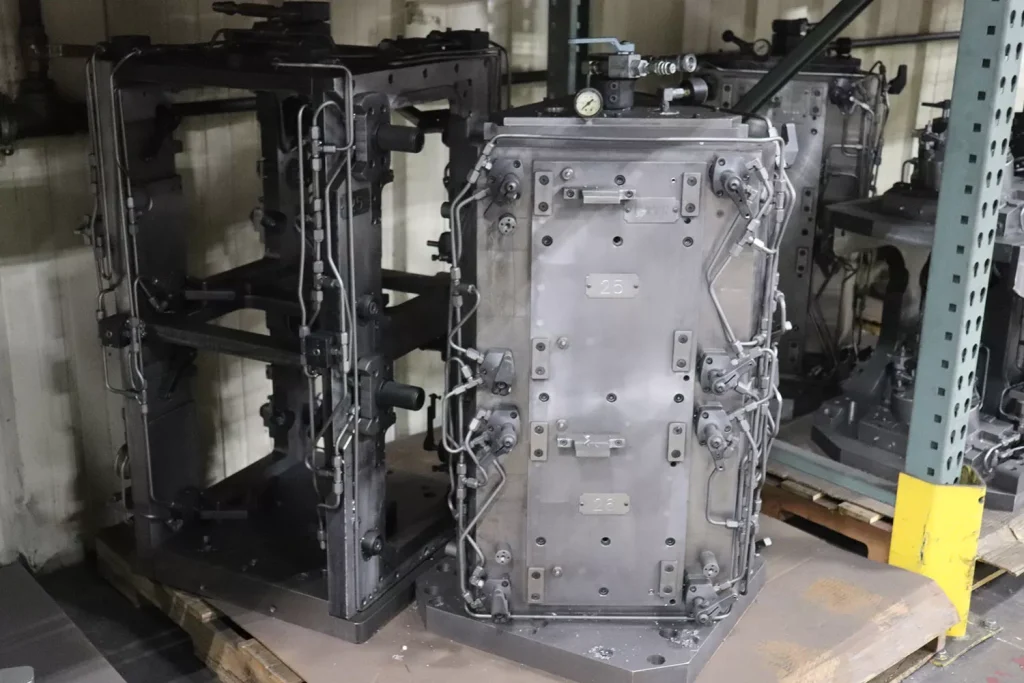

Custom Military Parts Manufacturing

Anpllocnc has extensive experience in manufacturing military and defense equipment. Over the years, we have become skilled in military and defense manufacturing as we have the resources, facilities and expertise required to get the job done.

We manufacture parts from armor plating for military vehicles such as the hemit vehicle, hummer, M915, and more. Materials often used include Titanium, HH, H480, H4100, AR236, AR400, AR500, Bullet-proof glass, Mil-A-46100, HY-80, HY-100, and Domex 100XF HSLA. Anpllocnc also has the ability to take care of any paint or finish specifications for defense or military parts as well.

Anpllocnc is a trusted source for military and defense manufacturing, we have handled enormous amounts of armor plating for several military and defense operations. If you have any questions about our manufacturing capabilities and facilities, please do not hesitate to ask.

AS9100D Precision Machining In The Military And Defense Industries

Manufacturing on Demand services provide high-quality manufacturing solutions for various military and defense equipment CNC military parts such as army equipment, naval equipment, military aircraft, military vehicles, air force equipment, marine corps equipment, coast guard equipment, etc.

To meet the high requirements and high standards of military instruments, Anpllocnc provides high-end military materials, advanced processing technology, and precision equipment to ensure high efficiency, high precision, precision tolerances, long service life, and excellent performance of the products.

Certified For Military And Defense

Anpllocnc is ISO 9001 certified and our have specialized certifications.

• ISO 9001

• AS 9100

• ISO 13485

• ISO 14001

• ISO TS16949

Comprehensive Quality Documentation

Get validation reports to ensure the highest quality and compliance.

• CMM Inspection Report

• Full Dimensional Inspections

• Material Test Reports

• Material Certificates

• Certificates of Conformance

• First Article Inspections

Highest Quality Standards

We use a rigorous set of protocols and procedures to maintain quality.

• Special tooling

• Sample size inspection

• Dimensional checks with calibrated equipment

• Review of all quality documentation and industry certifications

Delivering An Ironclad Supply Chain

From a security standpoint, yours is one of the most demanding industries in the world. If the supply chain for an electronics manufacturer suffers a breach, the worst that happens is that a few product designs wind up in the hands of a competitor. If a defense contractor is breached, it’s a matter of national security.

Because of this, implementation of machining processes and technologies tends to be significantly more challenging. It requires not only technical expertise, but also a comprehensive understanding of cybersecurity best practices. Luckily, that’s precisely what we deliver.

Defense Industry Applications

- Aircraft seat frames

- Aerospace couplers

- Retainer rings

- Missile components

- Flanges

- Fuser rollers

- Track hubs

- Main rotor hub

- Retainer rings

- Clamshells

Military And Defense Manufacturing Capabilities

CNC Machining

Milling, turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

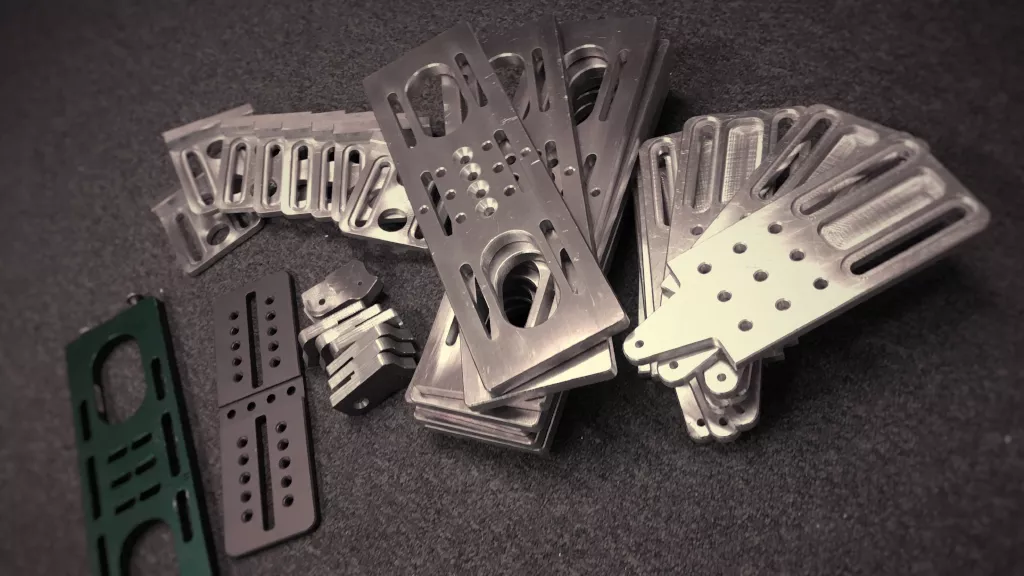

Sheet Metal Fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Rapid Prototying

Rapid Prototying production

- Wide range of part complexities and sizes

- 1 to 1M parts

Protect Your Production line

Advanced Supply Chain Optimization Through Anpllo

Connected technology and advanced automation is revolutionizing manufacturing across the board, and the defense industry is no exception in that regard. Accuracy, efficiency, and precision are crucial when designing the manufacturing process for the products and components in this sector. Choose a strategic partner that can deliver all three — while also prioritizing security.

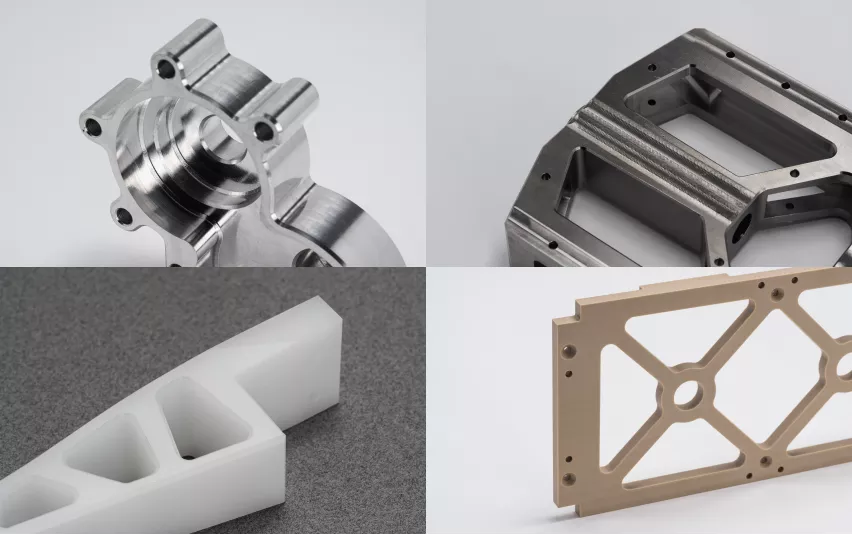

Materials & Surface Finishes For Military And Defense Parts

In addition to our precision machining capabilities, we offer a broad selection of Materials and finishing services to ensure we deliver complete parts and products to our customers. Our finishing capabilities include NADCAP certified.

Military And Defense Materials

Select from a broad range of industrial-grade materials

Aluminum alloys: Al 2024, Al 2014, Al 7050

Titanium alloys: Grade 1, Grade 2, Grade 5

Stainless steel: SS 304/304L, SS 316/316L, 17-4PH

Inconel: Inconel 718

Plastics: Ultem 9085, PA 6 Glass Filled, PA 12, PEEK, PTFE (Teflon)

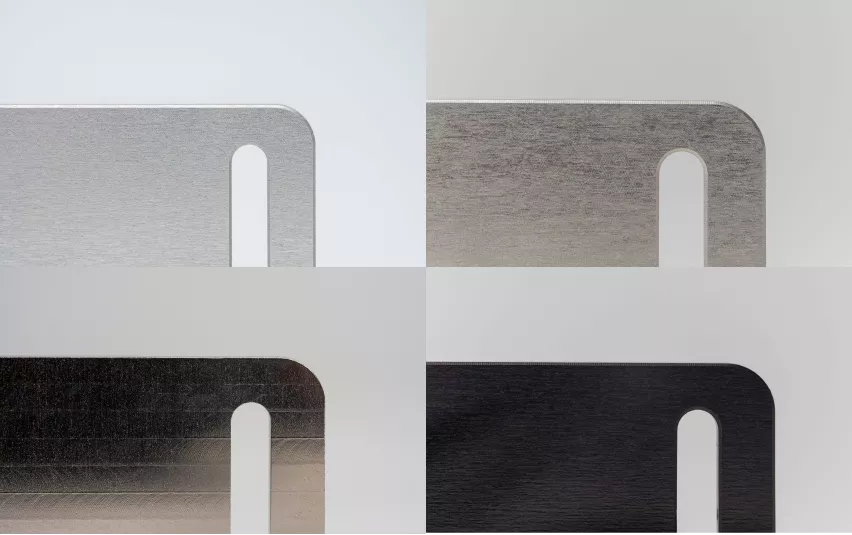

Military And Defense Surface Finishes

Select from these finishes to protect your parts

- Anodizing Type II (Cosmetic on request)

- Anodizing Type III (Hardcoat)

- Chromate Conversion Coating

- Brushing + Electropolishing (Cosmetic by default)

- Electroless Nickel Plating

- Black Oxide

- Zinc Plating

- Heat Treatments

High-Quality Custom Military And Defense Parts

How Anpllocnc Helps Military And Defense Companies

Our highly trained and knowledgeable design team will review your designs and military prototypes to ensure they are correct for the production process.

We’ve done many parts for the military, directly and indirectly. We prefer to work indirectly through you so if you have a military part to make, give contact us. We should be able to help.

Competitive Pricing, IP Protection, And DFM Guidance

Anpllo is the easiest way to get competitive prices and can be used to compare items on order quantities, lead times, materials, tolerances, secondary processes, and more. All final pricing information, including shipping, quality control, and customs clearance, is available. We prioritize IP protection throughout the part-production process to ensure your designs and models are completely secure. Our facilities include design for manufacturability (DFM) analysis, and our mechanical engineers are on hand to guide you.

Specified On Time Every Time

We adhere to comprehensive quality control processes and protocols to keep your supply chain consistent and robust. Our manufacturing partners complete a review process before joining the supply chain cooperation. On-site quality engineers will frequently conduct audits to ensure they meet Anpllo standards. Our in-house team checks parts’ functional and cosmetic specifications; we handle all customs clearance requirements and ensure on-time delivery.

Sourcing From Anpllocnc To Reduce Supply Chain Risk

Supply chain resiliency is critical, especially when you need parts on tight schedules and with specific certifications. We have a self-built factory to reduce your supply chain risk and provide procurement solutions that meet compliance requirements. Anpllo can provide the most comprehensive range of industrial 3D printing, CNC machining, injection molding, and sheet metal manufacturing services, providing consistent capabilities for your Military and Defense projects, no matter the scope.

Need a Quote? Have a Question?

Your sector is subject to some of the strictest regulatory requirements in the world. But that doesn’t mean you need to sacrifice innovation on the altar of cybersecurity. Work with Anpllocnc, and you can have the best of both worlds.