Rapid Prototyping and On-Demand Production for the Medical parts, components, and equipment manufacturing

New product development for the medical industry with on demand manufacturing. From rapid prototyping to mass production of medical products, enjoy reliable manufacturing services at competitive pricing.

- ISO 13485 | ISO 9001:2015 accreditation

- close-tolerance (±0.001mm)

- Medical machining capacities in the small to large (15,000 pounds)

Innovate Faster With Custom Manufacturing for the Medical Industry

Anpllocnc is a precision manufacturing company that specializes in creating medical equipment and parts through our rapid prototyping and low volume production services. Our cutting-edge manufacturing techniques include 3D printing, injection molding, die casting, and precision CNC machining,Sheet Metal Fabrication, which allow us to work with some of the top medical equipment manufacturers in the world.

With our extensive experience in manufacturing solutions for medical devices, we understand the unique and strict requirements of the health and fitness sectors. As a quality-driven, one-stop-shop for medical device innovation, we offer a range of services including bridge tooling, low-volume production, rapid prototyping, and material diversity. Our services are widely used to create a variety of medical devices such as fitness trackers, drug delivery devices, dental apparatuses, prosthetics, health monitors, and more.

We are proud to offer a range of manufacturing services that provide mass customization techniques, faster lead times, and no minimum order requirements, allowing our customers to get to market quicker. Our services are designed to help streamline the medical supply chain, accelerate innovation, and scale manufacturing for medical equipment makers.

Precision Medical Devices, Tools, and Components Machined in a Controlled Environment

Anpllocnc has a solid reputation for the precision manufacturing of quality medical equipment, tools, and components. We know the stringent compliance standards required by the medical industry. That’s why we’re committed to providing the reliability of supply that our medical customers demand. Our adherence to tight tolerances and in-depth understanding of customer and end-user needs allows leaders in the medical industry to rely on our state-of-the-art Manufacturing on Demand Services for a wide range of parts for their high-quality medical devices and equipment.

Instant quotes & DFM support

Quickly access pricing and lead times for unlimited complex parts.

• Confirm a price in within 12 hours

• Manage countless iterations of customized parts

• different designs to compare pricing options

• Receive instant DFM guidance

Rapid Manufacturing

Our fast, hassle-free service gets your parts to specification quickly.

• Every delivery is on time and within specification

• Different On-Demand Production options (delivery times from five days)

• Produce one-off or high-volume parts

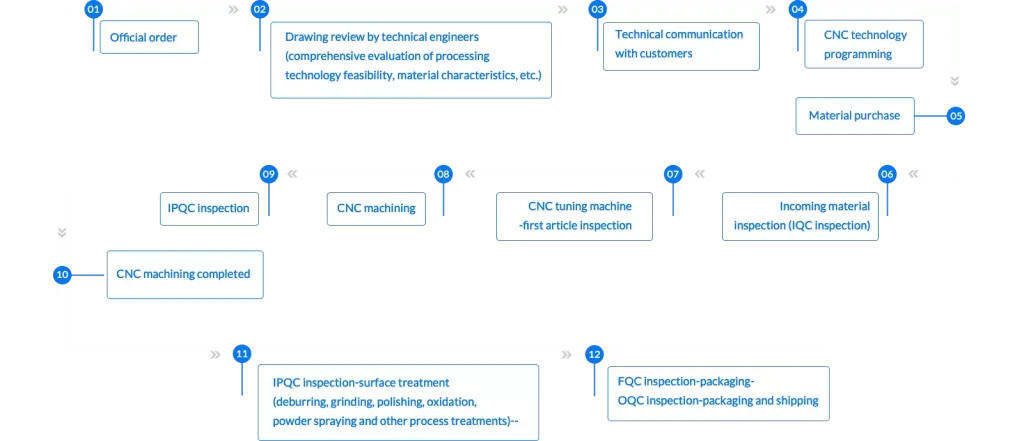

Our Service Process

Accelerating Medical Equipment Development and Prototyping

Anpllocnc manufactures solutions for some of the most distinguished medical companies in the world. Expansion of services, custom materials and industry experience allow North America and Europe Micro Industries to continually expand our technical capabilities to not only meet but exceed our customers’ requirements.

Materials are often essential in determining the quality, longevity and functionality of the finished product or component in the medical industry. In addition to providing precision manufacturing, maintaining sterility of all medical equipment is also key to ensuring the industry’s strict safety standards are met. Depending on what type of medical component or manufacturing design is needed, you can select from a wide range of materials that provide mechanical and physical properties.

Our success is a direct reflection of our dedication to quality and precision. Your specifications are critical, and we proudly offer the highest-quality materials. This ensures continued development of our manufacturing processes to provide innovative solutions. We go above and beyond to ensure your project is completed on time, on budget and beyond your expectations.

Medical equipment manufacturers have long trusted AMI as a reliable source of quality EMI shielding, microwave-absorbing materials and dielectric materials. From MRI machines to the latest state-of-the-art shielded enclosures and medical equipment, AMI has the experience and a track record that’s second to none when it comes to insulating material for medical equipment, such as Neoprene, Polyester Film, fish paper and dielectric material.

For more than 10 years, Anpllo Custom Components division has offered specialized and custom products and services for the medical and biotech industries. With exceptional quality and affordability, we have a longstanding history of meeting the technical, regulatory and mechanical requirements for all your custom medical component needs.

Some Of The Medical Components/Parts We Can Manufacture

We are a precision medical parts machining shop producing medical parts to the most demanding tolerances. This level of medical manufacturing utilizes the most sophisticated machining processes and cutting tools to ensure precision parts.

- Locking Pins And Nails

- Denture Models

- Expandable Rib Cages

- Defibrillators

- Prototyping

- Respirator Components

- Catheters

- Artificial Knees

- Surgical Scissors

- Bone Plates

- Vertebral Hooks

- Spinal Fusion Cages

- Clamps

- Tunnellers

- Spacers

Medical manufacturing capabilities

Our following machining capabilities have helped us gain prominence in the highly competitive medical industry.

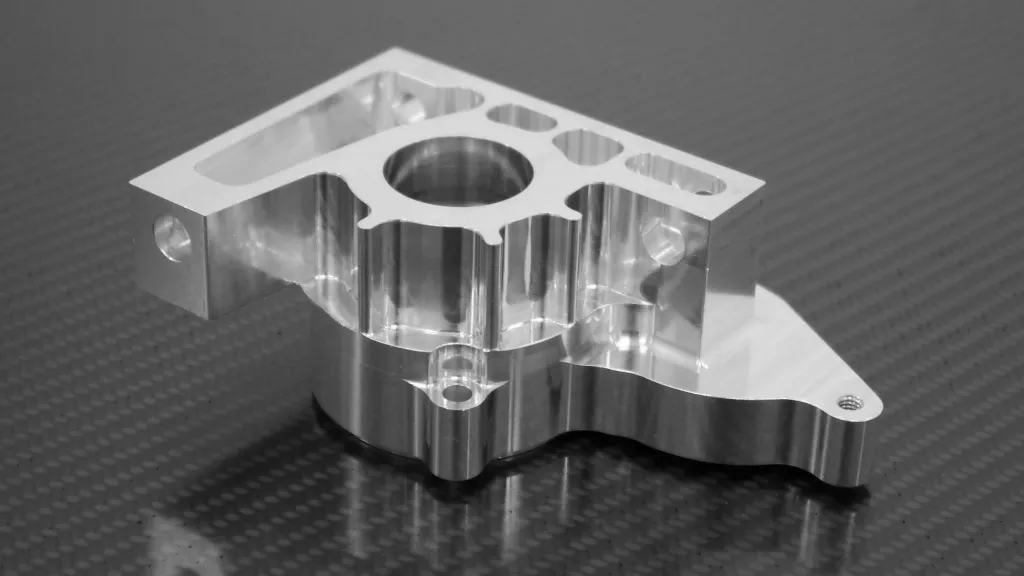

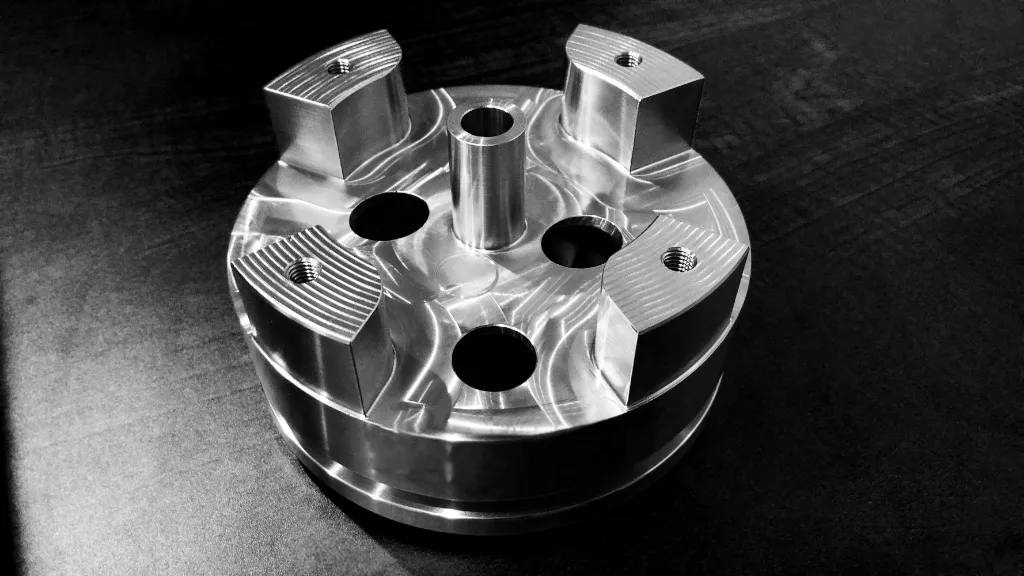

CNC Machining

Milling, turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

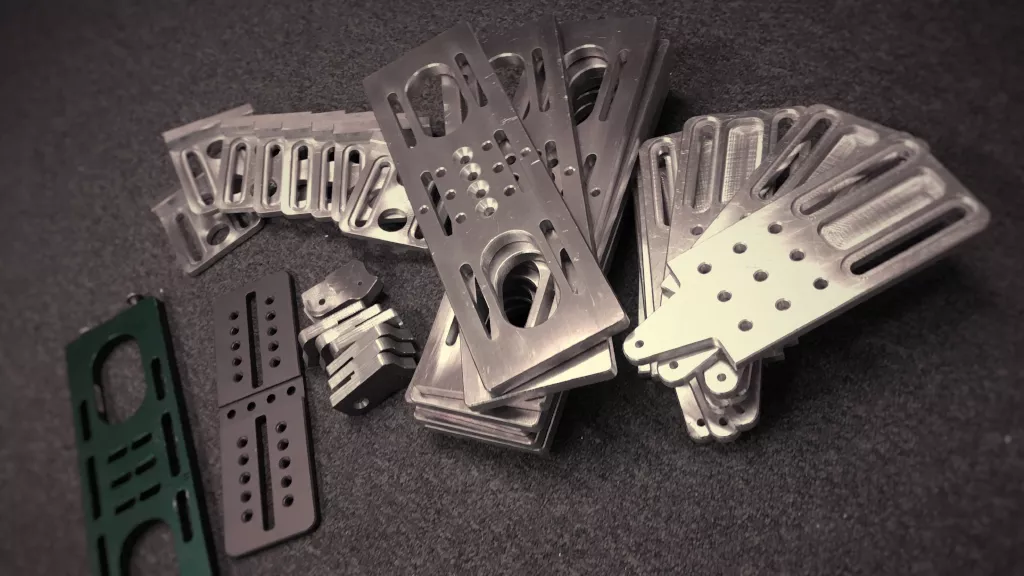

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Rapid Prototying

Rapid Prototying production

- Wide range of part complexities and sizes

- 1 to 1M parts

Why Do Medical Device Development Companies Use Anpllo?

Interactive Design Analysis

Make critical design adjustments that save development time and cost with design for manufacturability (DFM) feedback on every quote.

Bridge Tooling Before Production

Leverage affordable bridge tooling for design and market validation before capital investment in tools.

Medical Materials

Choose from high-temperature plastics, medical-grade silicone rubber, and 3D-printed micro-resolution and microfluidic parts, among hundreds of other plastic, metal, and elastomeric materials.

Low-Volume Production

Get low-volume production parts in as fast as 1 day to streamline your supply chain once before and after products are launched to market.

Technology Agnostic

Multiple manufacturing technologies across four services mean your parts are paired with the right equipment and process regardless your project needs.

Rapid Prototyping

Create prototypes in production-grade materials for functional and regulatory testing, or use our 3D printing service to print models and organ scans to preview before medical procedures.

Materials & surface finishes for Medical Device parts

Material choice is a very critical step in medical machining. Medical machining entails the employment of an extensive array of materials that explicitly befit healthcare applications. We routinely deal with medical-grade materials, ensuring all devices and components are faultlessly in line with the relevant regulations.

Materials for Medical

Choose from more than 30 metal alloys and hundreds of plastics.

We’re capable of machining a diverse range of materials including but not limited to Titanium, Stainless Steels, Beryllium, Chromium, Bronze, Brass, Hastelloy, Chrome Alloys, Copper, Invar, Manganese, Molybdenum, Ceramics, Acetal, PEEK, ABS, PVC, UHMW, Inconel, Monel, Peek, Kovar, Silver, Silicone, Nylons, Polymers, and Composites. We also offer the service of silver and gold plating wherever requested.

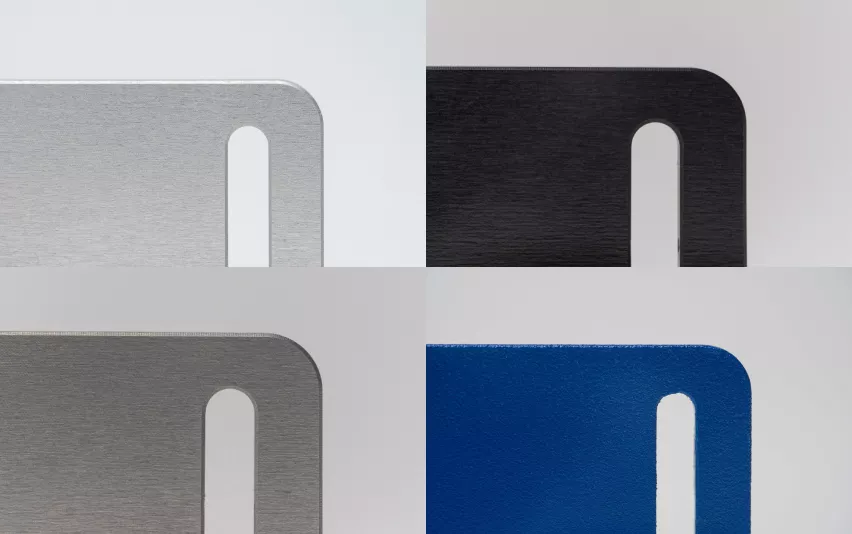

surface finishes

Improve durability and performance with a selection of finishes

- Anodizing

- Electroless nickel plating

- Black oxide

- Chromate conversion coating

- Powder coating

- Passivization

- Insert installation

- Heat treatment

Custom Prototypes and Parts for Medical Devices Industry

How Anpllo helps Medical companies

The very nature of devices, regarding the medical applications (Surgery, implants, diagnostic, etc.), is such that a single small error or imperfection can be a matter of life or death. To ensure precision and accountability, we rely on a variety of state-of-the-art CNC machines along with a squad of adept engineers. We provide the unfailing/life-saving precision medical prototypes and products within extremely tight tolerances to precise specifications while sustaining the scrupulous standard of ‘periodic communication’ and ‘timely delivery’.

Competitive pricing, IP protection and DFM guidance

Anpllo is the easiest way to get competitive prices and can be used to compare items on order quantities, lead times, materials, tolerances, secondary processes, and more. All final pricing information, including shipping, quality control, and customs clearance, is available. We prioritize IP protection throughout the part-production process to ensure your designs and models are completely secure. Our facilities include design for manufacturability (DFM) analysis, and our mechanical engineers are on hand to guide you.

To spec and on time, every time

We adhere to comprehensive quality control processes and protocols to keep your supply chain consistent and robust. Our manufacturing partners complete a review process before joining the supply chain cooperation. On-site quality engineers will frequently conduct audits to ensure they meet Anpllo standards. Our in-house team checks parts’ functional and cosmetic specifications; we handle all customs clearance requirements and ensure on-time delivery.

Sourcing from Anpllo to reduce supply chain risk

Supply chain resiliency is critical, especially when you need parts on tight schedules and with specific certifications. We have a self-built factory to reduce your supply chain risk and provide procurement solutions that meet compliance requirements. Anpllo can provide the most comprehensive range of industrial 3D printing, CNC machining, injection molding, and sheet metal manufacturing services, providing consistent capabilities for your aerospace projects, no matter the scope.

FAQ’s

Importantly for surgical equipment and other complex and sensitive medical components, a single error can lead to serious problems. This is what makes precision a priority and extremely important in medical processing. With medical CNC machining, you can achieve tighter tolerances and maximum and high precision in your parts. Custom medical parts for precision medical machining must fit perfectly and meet the design and precision needs of the part.

The conditions that need to be met for the manufacture of medical parts:

- tighter tolerances

- medical grade material

- advanced machining

- Advanced technology equipment

- knowledgeable staff

- strengthen control

Tighter tolerances down to +/- 0.02 mm are a requirement in the medical industry. Also, the tightest tolerances of +/- 0.001 mm are only achievable upon your specification.

Methods for achieving stability and tighter tolerances are:

- Suitable manufacturer experience and machinery

- Controlling Medical Processing Environments

- Perfect quality control process and stable temperature

- Eliminate misalignment, asymmetrical designs, concentricity errors

- Use the correct sharp-cutting tools

- Selection of medical-grade materials

- Detailed and complete process quality inspection

In addition, experienced engineers and strong quality control of medical parts manufacturers can help you achieve tighter tolerances.

Does your medical project require Rapid Prototyping and On-Demand Production?

Anpllocnc has supplied custom medical components to many clients worldwide. If precision and quality management are your top priorities, you can rest assured that our team will serve you with the utmost sincerity.