Manufacturing On Demand For Automotive Product Development

Customized automotive prototyping and component manufacturing services for automotive product development. Streamline the manufacturing process, get competitive pricing, and produce on demand through rapid prototyping and low-volume production.

- Tight tolerances & complex geometries

- Huge selection of durable & resistant materials

- Get full IP protection and quality documentation

Custom Automotive Component Manufacturing

Custom automotive component manufacturing makes the production of high-quality custom parts, like gaskets, seals, attachments, fastenings and anti-vibration foam, possible. Many original equipment manufacturers rely on auto parts manufacturing companies to produce automotive components meeting their standards. These auto parts must be compatible with particular vehicles, providing top-tier performance and lasting a long time. Any automotive component manufacturer should offer quality-assurance and testing services to ensure product-quality before these parts reach consumers.

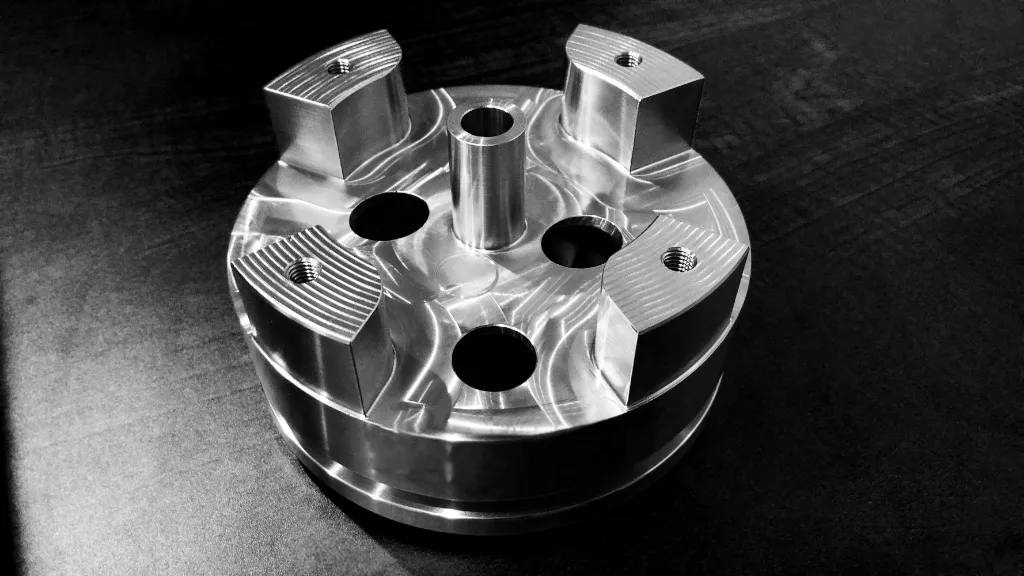

At Anpllocnc, we provide high-quality automotive components to many original equipment manufacturers. Our custom automotive component manufacturing utilizes CNC machining and Sheet Metal Fabrication solutions to craft components to meet our client’s exact specifications. We operate out of a cutting-edge machine manufacturing facility outfitted with modern equipment designed to produce parts quickly and with incredible accuracy.

Whether it’s parts for under the hood, for doors or wheels, or whether it’s interior or exterior; custom gaskets, seals, or any other custom parts, Anpllocnc is here to help. We use waterjet cutting and custom laser cutting to manufacture parts from prototype to production, no job is too difficult.

At Anpllocnc, we’re able to custom manufacture your parts with precision, efficiency and quality. We can produce parts for the automotive industry from carbon steel, stainless steel, composites, plastic, rubber, ballistics, aluminum, and many other materials. Parts that can be manufactured at Anpllocnc may include spoilers, lift gates, frames, engine cradles, moldings, fenders, splitters, panel parts, seat frames, seat bases, and more.

Our team of expert CNC professionals regularly engineer automotive components for a client’s unique specifications and requirements. During engineering, our team relies on top CAD/CAM software, like Virtual Gibbs CAM and AutoCAD, to ensure our components meet design standards and perform at their best. At every step of the custom automotive component manufacturing process, our team follows strict quality guidelines.

Focus On Industry Standard

The automotive industry demands products that meet exact specifications and the highest standards for reliability and quality. Through a combination of technology and in-house engineering and manufacturing expertise, we are able to design, manufacture, and deliver the highest quality products and sub-assemblies in the industry. Our machining processes and equipment ensure quality, control, and performance for the most demanding jobs, including lightweight, high-temperature, low-temperature, and high-corrosion applications.

We strive to be a trusted partner to automotive suppliers, providing them with exceptional value, cost-efficiency, and uncompromising quality. Our commitment to continuous improvement and comprehensive manufacturing processes enables us to deliver parts that meet and exceed industry standards.

Certified For Automotive Manufacturing

Anpllocnc is ISO 9001 certified.

• ISO 9001

• IATF16949

• ISO 13458

• ISO 14001

• ISO TS16949

Comprehensive Quality Documentation

Get validation reports to ensure the highest quality and compliance.

• CMM Inspection Report

• Full Dimensional Inspections

• Material Test Reports

• Material Certificates

• Certificates of Conformance

• First Article Inspections

Highest Quality Standards

We use a rigorous set of protocols and procedures to maintain quality.

• Special tooling

• Sample size inspection

• Dimensional checks with calibrated equipment

Rapid Manufacturing Of Car Prototypes

Prototyping is a critical step in developing automotive technology and new parts. Whether you need a few complex parts or thousands, our project team can quickly quote and deliver assemblies within days. We can also quickly scale from prototyping to low-volume production and deliver parts instead of First Article Tool (FOT) while you are still looking for a volume supplier.

Typical Precision Machining Automotive Components

- Prototyping

- Intermediary & replacement parts

- Autonomous driving systems

- Electrical vehicles and charging parts

- Manufacturing line jigs & fixtures

- E-bikes and scooters

- Commercial & utility vehicle parts

- Jigs & fixtures

- EV battery testing components

- Parts for resurrecting older technologies

Our Commitment To Customer Satisfaction

With our in-house team of highly skilled professionals, we’ve implemented solutions for a vast range of vehicle types. We also maintain strict regulatory standards to ensure all work performed meets design specifications and safety requirements across the board.

Our staff provides clients in the automotive industry with custom die cut components for numerous types of vehicles, and we offer cost-effective solutions with no sacrifice to quality. Even as our business continues to expand and we continue to elevate our profile across the far reaches of the auto sector, our commitment to improvement is unwavering.

For anyone in need of custom manufacturing for automotive industry components, we can help you with every step of the process toward implementing the right solutions for your vehicles. Furthermore, we have a dedicated team of customer service representatives who will happily answer any questions and offer support throughout the buying and ordering process.

Anpllocnc’s Machining Capabilities For Automotive Industry Components

In the Automotive Industry, precision machined parts are crucial to producing a quality end product. Vehicles are complex structures made of many parts. Skilled machinists at Anpllocnc have automotive industry knowledge to ensure parts are made to meet customer requirements. Our engineers will partner with customers to analyze drawings and provide recommendations on automotive industry part design. We serve as a Tier 2 and 3 supplier to automotive OEMs.

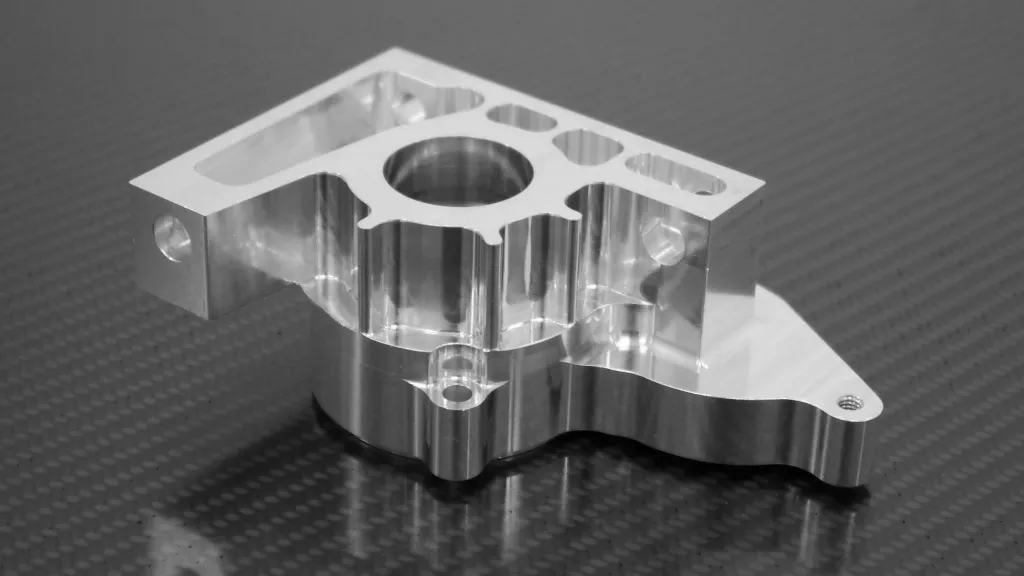

CNC Machining

Milling, turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

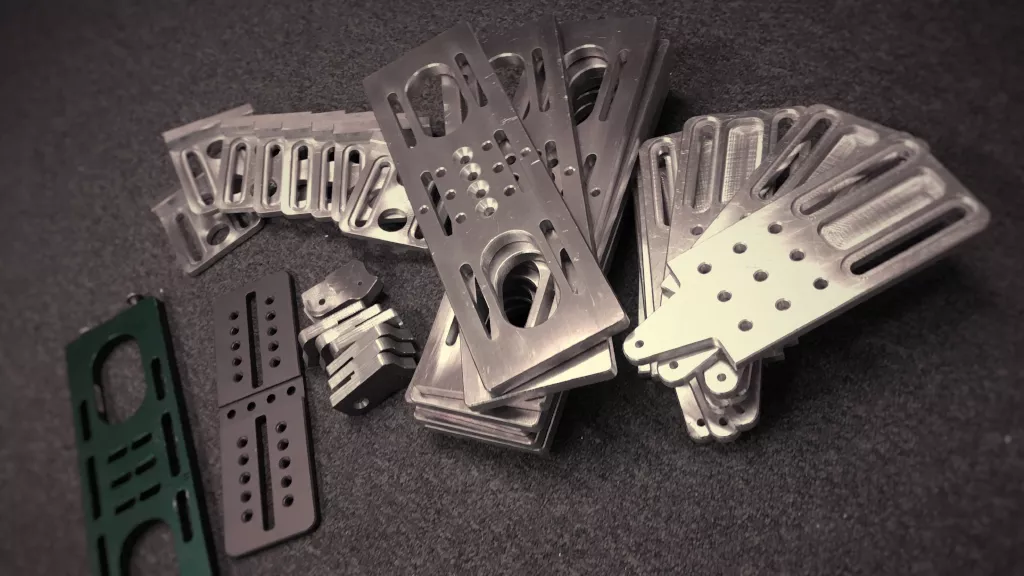

Sheet Metal Fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Rapid Prototying

CNC Auto Parts Prototye production

- Wide range of part complexities and sizes

- 1 to 1M parts

Materials & Surface Finishes For Automotive Parts

We give you access to a huge range of materials and surface finishes for every application.

Automotive Materials

Select from a broad range of industrial-grade materials

Steel, mild steel & stainless steel: 304/304L, 316/316L, 430, 301, 4140, 4340, Tool Steels

Titanium: 1, 2, 5

Aluminum: 6061-T6, 6063, 5052, 5083-H111, 2017, 7075-T651

Thermoplastics: Polyethylene (PE), Polypropylene(PP), Polycarbonate (PC), ABS

Commodity polymers: Polyethylene terephthalate (PET), Polyvinyl chloride (PVC)

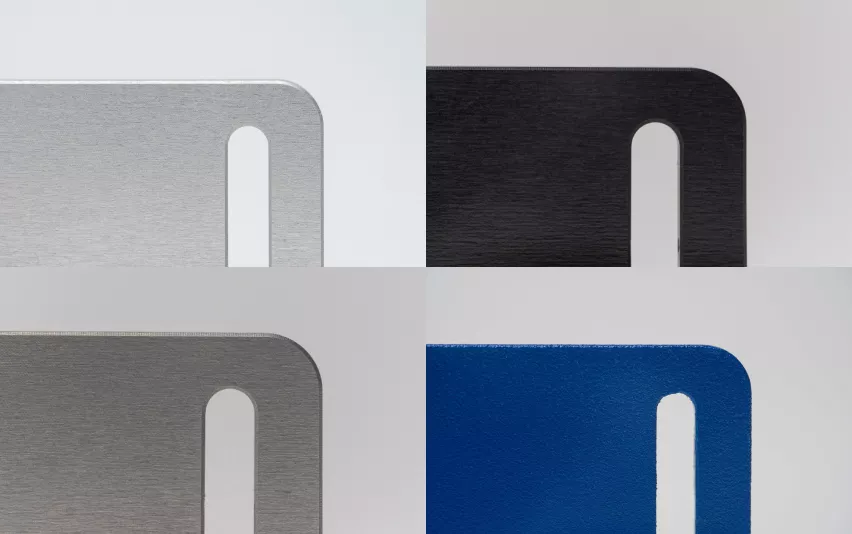

Automotive Surface Finishes

Select from these finishes to protect your parts

- Anodizing

- Powder coating

- Electroless nickel plating

- Polishing

- Insert installation

- Heat treatment

- Passivization

High-Quality Custom Automotive Parts

How Anpllo Helps Automotive Companies

Our massive range of customer focused services allow you to iterate rapidly and offer customised solutions to your clients fast.We understand the demands of the automotive and transportation industries and work with you to ensure they are met and exceeded.

Advanced Processes Solve Complex Geometries

Our fabrications can achieve incredible geometric complexity. No matter your design’s complexity, we can produce any product with superior mechanical and cosmetic properties. Our capabilities include CNC technology, including 5-axis machines, to easily produce rapid prototypes and low-volume production parts.

Timely Quotes And Design Support Save Time

When you need to innovate quickly and get your project to market, time is not on your side. Work with Anpllo instead of waiting weeks for a quote; use our engineers for instant pricing and advanced DFM analysis to get parts into production faster. You’ll never be one step behind the competition because of production issues. Whether you need to manufacture tooling equipment for testing, need individual parts, or update technology to meet the era of vehicle electrification, Anpllo can meet your needs.

Work With Top Notch Mechanics

Our automotive engineers and experienced mechanics are ready to help you create innovative products and keep your projects on track. Instant quotes and DFM analysis services from Anpllo’s project team can tailor plans to your production needs. We know how to save your workshop time and effort and how to use parts in every aspect of the automotive industry.

FAQ's

The effectiveness of any manufacturing method depends on how it is applied. For example, CNC machining of automotive parts is a versatile method capable of producing a wide range of parts and quickly becoming popular across the industry.

CNC machining is the fastest way to produce parts compared to other manufacturing methods. The delivery time and cost of CNC machining parts are mainly affected by the materials used in the parts and the complexity of the design. For more information, you can contact us.

Contact Anpllocnc For Custom Automotive Industry Components

When it comes to performance, safety, comfort and efficiency, few industries are held to as high of a standard as the automotive sector. It’s all because of the trust, care and capital that motorists put into their passenger vehicles.If you are an automotive supplier seeking reliable and high-quality metal parts production, please feel free to reach out to us. Our experienced team is ready to discuss your specific needs and provide tailored solutions to support your success in the automotive industry.