Wire EDM Machining Service

Anpllocnc is a premier wire-cut EDM outsource supplier and provider of wire EDM services. Our team partners with a broad cross section of industries to supply high-precision prototypes, medium-volume runs, and long-term, high-volume EDM component production services.High-

Our Service

Since its establishment, Anpllocnc has been providing reliable and affordable CNC wire cutting machining solutions. As one of the top wire EDM Machining companies in China, we have the in-house capabilities to execute various wire EDM processing projects. We are an ISO and AS certified small business and a full service machining solutions provider. We can produce custom precision wire EDM machined parts with quality and performance that will exceed your expectations.

Our ongoing investment in technology, people and equipment allows us to stay at the forefront of processing innovation and continue to provide exceptional value to every customer, whether it’s a large company with hundreds of employees or a ten-person need to be cost-effective A solution for small machining jobs in the workshop. We are able to provide specialized machining services that are beyond the reach of many of our competitors, allowing our customers to remain viable in today’s challenging global marketplace.

Instant Quote For Custom Wire EDM Machining Parts

Anpllocnc provides Wire EDM Machining services and instant quotes for your Wire EDM parts. Our customer service team will work with you to ensure your design specifications are met. Follow these steps to order parts easily:

Create or upload your CAD files: Use our free online quoting system to upload your CAD files, PDF drawings or images for instant quotes and FDM analysis.

Configure your part: choose from over 50 materials and finishes. Enter the quantity, address, and any special comments for the mechanic.

Receive Quotations: The system generates online quotes for the parts you design.

Order Your Parts: Place your order like us and receive quality parts!

Capabilities

- Hole Popper EDM

- Wire EDM

4 Axis

In-House Fixturing & Tooling

Up to 13.5″

Up to 19.5″

Up to 10.5″

0.003″ to 0.12″

0.008″ to 0.0012″

17° for 4″ Thick Material

±0.0002″

- Aluminum (All Alloys)

- Beryllium Copper

- Brass

- Bronze

- Copper Nickel

- Copper

- Nickel Alloys

- Nickel Silver

- Phosphorous Bronze

- Spring Steel

- Stainless Steel (2B, #3 & #8)

- Steel (CRS, HRPO & HRS)

- Titanium

- Tool Steel

- CMM Equipment

- Hardness Testers

- Laser Scanners

- Master Gauge Blocks

- Optical Comparators

- Pull Testers

- Deburring

- Glass Bead Blasting

- Graining (Brushed Finish)

- Polishing

- Sand Blasting

- Vibratory Tumbling

Anodizing

- Bright Dip

- Standard (Multiple Colors)

- Hard Coat

Barrel Plating

Black Chrome

Black Oxide

Bright Nickel

Brush Nickel

Cadmium

Chromate (Clear or Yellow)(Also known as Iridite or Chem Film)

Chrome

Copper

Etching

Electroless Nickel

Electropolish

Gold

Hard Chrome

Passivation (Nitric of Citric)

Phosphate Pretreat)

Rhodium

Silver

Tin

Zinc (Clear, Yellow or Black)

- Hexavalent

- Trivalent (RoHs Compliant)

Zinc Cobalt

Plating Certified to AS9100, ISO, ITAR & NADCAP

- Dielectric Paint

- E-coating

- Powder Coating

- PTFE

- Wet Paint

Assembly

Centerless Grinding

Engraving

Heat Treating

- Ink Fill

Kitting

OD Grinding

Silk Screening

- Consignment Programs

- Custom Stocking

- Programs

- Customer Portal

- Management

- JIT Shipping

- Kanban

- Min-Max

- Vendor Managed

- Inventory

- Blanket Orders Accepted

- High Volume

- Low Volume

- Prototypes

- Small Quantities Typical

- 1-2 Week Expedited

- Service Available

- 2-4 Weeks Typical

- Specific Lead Time

- Quoted on a Job by Job Basis

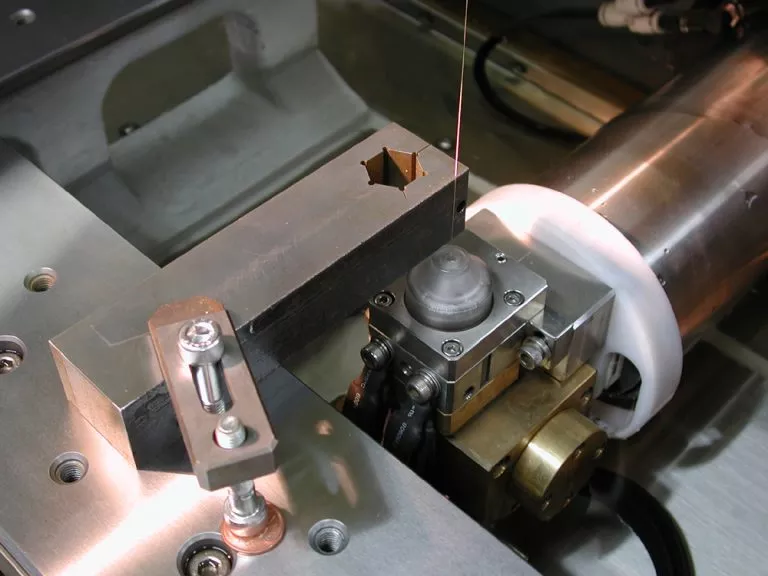

EDM Equipment Listing And Specifications

| AgieCharmilles AC Progress V2 Wire EDM | Work Piece Dimension: | 29.5″ x 21.65″ x 9.8″ |

| Work Piece Weight | 992lbs | |

| Table Travel | 13.75″ x 9.8″ | |

| Taper Angle | ±30° | |

| Fanuc α1 iC EDM | Work Piece Dimension: | 41″ x 28.7″ x 12.2″ |

| Work Piece Weight | 3550 lbs | |

| Table Travel | 21.7″ x 14.6″ | |

| Taper Angle | ±30° | |

| Methods Hole Master CNC EDM Drilling System | Work Piece Dimension: | 15.75″ x 15.75″ x 12″ |

| Work Piece Weight | 1325 lbs | |

| Resolution | .00004 (4-axis) |

Manufacturing Specifics

- Advanced 5-Axis CNC Wire EDMs built for efficient 24/7 operation

- Multiple wire electrode sizes from 0.0120″ down to as small as 20um (0.0008″) in diameter

- Multiple wire electrode materials are used like brass, copper, molybdenum and tungsten

- Extremely consistent cut quality due to the wire electrode being cycled between spools during the cutting process

- Workpieces up to 8″ thick are easily machined using Wire EDM

- Simultaneous machining of multiple parts using stacked Wire EDM techniques

- Standard machining tolerances of 0.0010″ to 0.0005″ and high precision tolerances as tight as 0.0001″ (2µm micron)

- Micromachining Fine Wire EDM tolerances of 1µm and below

- Wire EDM finished 30 micron diameter holes

- Feature Aspect Ratios up to 38:1

- Surface Finishes down to 4Ra µin (micro inch) eliminate finishing and require no additional polishing

- Small quantities of 1-50+ pieces with quick turnarounds

- Contract Manufacturing of full production quantities of thousands of pieces

What is Wire EDM?

The Wire EDM (Electrical Discharge Machining) process uses a thin single strand of wire, which is fed through the workpiece in conjunction with high pressure deionized water. Multiple miles of wire electrode held on wire spools is fed between two guide rollers, much like the blade on a band saw, that are then driven in a path controlled by the CNC machine control. During this EDM metal cutting process, electric current is used to erode away the conductive materials of the workpiece and leave behind an extremely smooth and uniform surface that requires no additional finishing or polishing processes. This wire electrical discharge machining process is typically used when low residual stresses in the workpiece material are desired, as there is little change to the mechanical properties of the material. During this process, the cutting wire electrode doesn’t ever touch the workpiece material. Instead, the EDM cutting takes place when electrical sparks form between the material and the cutting wire in what is referred to as the voltage gap. Highly filtered, deionized water is used because it deionizes the spark gap, flushes away the metal particles removed by erosion from the workpiece, and acts as a cooling medium to keep the machining temperatures stable. Wire EDM machining is widely used within a multitude of industries for creating components by cutting intricate shapes in numerous conductive and oftentimes delicate materials.

How Does Wire EDM Work?

As with all EDM machining, measured voltages between two electrodes are required to produce a current of electricity. These electrodes create a spark, generating temperatures of over 14,000°F to vaporize and erode the material being machined.

With wire EDM, voltage is sent through the wire and a current path is established between the workpiece and the wire, which serve as the two electrodes. A precise servo motor ensures a constant gap between the wire and the piece. If the wire were to touch the workpiece, a short circuit would occur, stopping the process.

In some ways, it is helpful to compare the wire EDM cutting action to that of a band saw, except the teeth of the band saw are replaced with the spark, which jumps from the wire to the workpiece nearly a million times per second to erode the material. Eroded materials shed from the workpiece are no larger than specks of dust.

Like a band saw, the thin wire is spooled and constantly fed between two computer-assisted guides. This constant spooling action provides a fresh cutting surface throughout the wire cutting process. Because the cutting action produces constant erosion of both electrodes, long lengths of wire must be used – around 11 miles long (19 km) – and spools can weigh about 18 pounds, depending on the wire’s gauge. Once the cutting dimensions are entered into the CNC machine, the process is ready to begin.

What Advantages Do Custom Wire EDM Machining Parts Offer?

EDM wire cutting machining services provide numerous benefits that can be custom utilized to your exact project specifications. Some of the added benefits of EDM machining services include:

- Cuts complex shapes.

- Can cut extremely hard material to very close tolerances.

- Manufactures very small workpieces where conventional cutting tools may damage the part.

- Delicate sections and weak materials can be machined without distortion since no direct contact is made.

- Provides a good surface finish.

- Very fine holes can be achieved.

- Capable of manufacturing tapered holes.

- Can produce pipe or container internal contours and internal corners down to R .008″.

Applications

Wire EDM-manufactured parts are regularly used for industrial applications throughout the world. Industries rely on EDM wire machining components manufacturers to produce the products they require to succeed. Some of the direct applications related to wire EDM services include:

1. Medical Device Manufacturing: As wire EDM machining makes it possible to cut or mold materials like steel without heating it, this method is an ideal choice of medical device manufacturers. With this method, the manufacturing of several life-saving instruments made from carbon steel becomes easier.

2. Tool, Die and Mold Making: With the help of EDM machining, it is possible to create very fine holes and profiles. Thus, electrical discharge machining is often used in the production of Molds, dies and Custom tools & Fixtures.

3. Military and Aerospace Applications: EDM is used widely in the military and aerospace industries to produce parts for important equipment. EDM are used to cut several aerospace parts.

4. Automotive Industry: In a competitive automotive industry, it is necessary to have short cycle times, and cutting costs. These are offered by EDM. Owing to its efficiency and accuracy, automotive manufacturers also turn to wire EDM.

contact us

Online instant free wire cutting service quote

Anpllocnc can provide precision wire-cut electrical discharge machining services and high-speed small hole electrical discharge machining services worldwide. Our production experience and equipment capabilities allow us to take on any size or type of project and deliver it to you on time.