Small Hole EDM Services

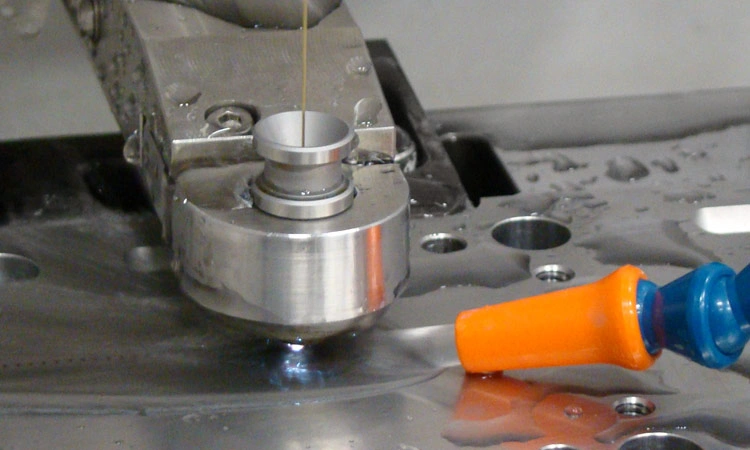

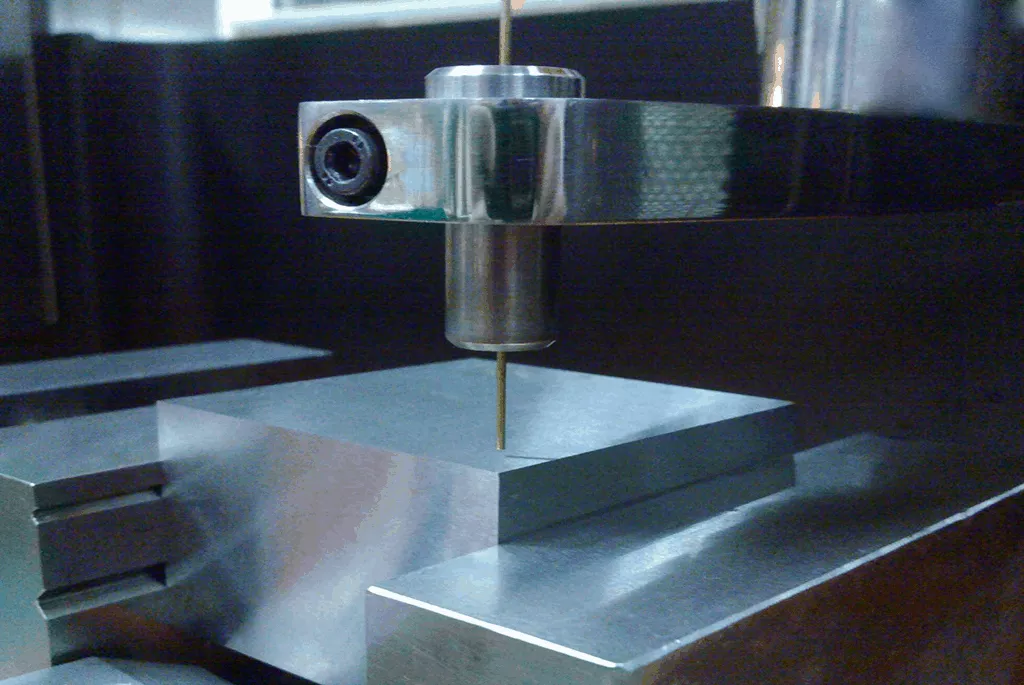

We are constantly looking to go beyond our customers’ expectations in small hole services. By being on the leading edge of the industry for micro hole, small hole and fast hole (high speed drilling) we have set ourselves apart from the competition. Small hole EDM, or EDM Hole burning compliments and aides our wire EDM machines by quickly generating starter holes through seemingly impossible-to-drill materials or thicknesses, greatly reducing cost and turnaround time for our customers.

CNC Small Hole EDM Services

Anpllocnc offers unique, CNC small hole EDM drilling services of blind and through holes in a wide variety of electrically conductive materials. Our purpose-built CNC-operated EDM small hole drilling machines can produce hole diameters as small as .012″ to .250″ with an accuracy of .001″ and fast burn times. High precision micro hole sizes, excellent hole edge quality, superior surface finish, improved overall part accuracy and excellent hole consistency is achieved through the use of cutting-edge EDM generator technologies. Our integrated CNC rotary index tables with tool changers, allow for quick cycle times. Our advanced materials also reduce the electrode wear encountered during the spark machining process. The lower the wear of the electrode, the more holes each electrode can machine before it needs to be replaced.

Small hole EDM parts online quote

Anpllocnc is a provider of small hole EDM services. We service customers across a wide array of industries to drill close proximity micro holes too small or difficult for conventional drilling.Upload your part design now to get an instant online quote.

Small Hole EDM Capabilities

- Electrical Discharge Machining (EDM) Drilling

- Wire Electrical Discharge Machining (EDM)

3-Axis

- Alloy Steel

- Aluminum

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Molybdenum

- Nickel

- Stainless Steel

- Tin

- Titanium

- Tungsten

- Gold

- Inconel®

- Invar®

- Iridium

- Kovar®

- Monel®

- Niobium

- Palladium

- Platinum

- Silver

- Superalloys

- Tantalum

- Maximum Length: 12.0 in

- Maximum Width: 8.0 in

- Maximum Thickness: 20.0 in

- Minimum Hole Diameter: 0.013 in

- Maximum Hole Diameter: 0.25 in

- AutoCAD (DWG, DWZ)

- DXF (Drawing Interchange Format, or Drawing Exchange Format)

- IGES (Initial Graphics Exchange Specification, ANSI File Format)

- PDF (Portable Document Format)

- SolidWorks (SLDPRT, SLDDRW, SLDDRT)

- STEP (Standard for the Exchange of Product Model Data)

- Compute Aided Design (CAD) Services

- Computer Aided Manufacturing (CAM) Programming Services

- Reverse Engineering

- Prototype

- Low Volume

- High Volume

- Blanket Orders

- Quoted on Job by Job Basis

- Emergency Services Available

- Rush Services Available

- Lights Out Manufacturing

- Lean Manufacturing

- Aerospace

- Automation

- Automotive

- Biomedical

- Biopharmaceutical

- Biotechnology

- Chemical Manufacturing

- Commercial

- Communications

- Consumer Goods

- Dental

- Defense Industry

- Electrical

- Electronics

- Energy

- Extrusion Dies

- Firearms

- Food Production

- Food Handling

- Food Processing

- Food & Beverage

- Industrial

- Injection Molding

- Laboratory

- Machine Tools

- Machinery

- Manufacturing

- Marine

- Medical

- Medical Devices

- Military

- Molding

- Nuclear

- Optical

- Packaging

- Pharmaceutical

- Pumps

- Railroad

- Research

- Robotics

- Semiconductor

- Specialty Machinery

- Surgical

- Tool & Die

- Universities & Learning Institutions

Small Hole EDM Advantages & Benefits

Small Hole EDM offers a range of advantages and benefits, including:

- Ability to drill on curved and angled surfaces. Without the electrode coming into contact with the material being cut, it is easier to drill on curved or angled surfaces when using small hole EDM.

- Drilling hard, high strength alloys. Hardness does not affect the small hole EDM drilling process, making it the only drilling method for some materials.

- Drilling of softer metals. Softer materials, such as aluminum and copper, often produce chips that cling to cutters. With small hole EDM, drilling of such materials is easily completed without the creation of chips.

- Deep hole drilling. Small hole EDM drilling is usually the only practical solution for creating deep small holes. South Shore Manufacturing can drill to depths up to 20″.

- Burr-free and straight holes. The no-contact process of small hole EDM drilling produces straighter holes that are difficult to obtain with traditional drilling due to drifting. The burr-free holes created with small hole EDM drilling saves time from deburring that’s necessary with conventional drilling.

- Prevents broken drills. Since the electrode in small hole EDM drilling does not come in contact with the workpiece, it eliminates improper torque conditions, preventing broken drills.

- Increased Precision. Being able to program diameter, depth, and hole placement in small hole EDM machines increases control and enhances precision.

Other Services

We offer precision wire EDM services, precision sinker EDM services, micro hole popping and burning, and more. We also offer a comprehensive selection of secondary EDM services, which includes heat treating, descaling, anodizing, hard coating, and more.

- Rapid Prototyping

- Reverse Engineering

- Inspection

- Laser Marking

Create your own

Need Your Parts Quickly?

Upload your CAD files now and get a quick quote!