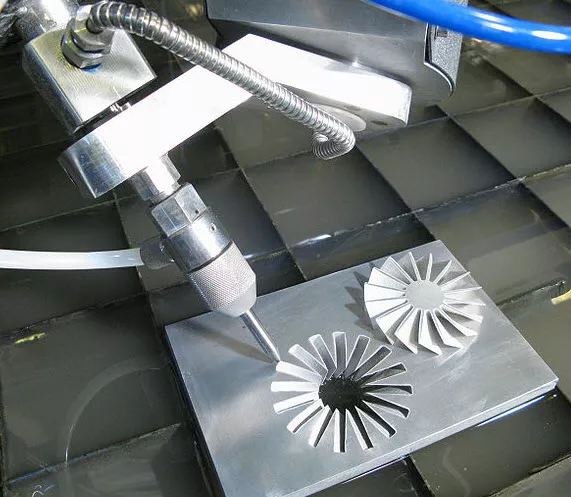

Waterjet Cutting Services

Every job is unique, and many require special considerations for materials, finishing, custom work, or urgent delivery – your commercial quote will be turned around by seasoned estimators who confirm all aspects of your job.

Anpllocnc offers a cost-effective waterjet cutting solution whether you need a single part, batch of prototypes, or a production order. Our Waterjet Cutting Services Are Available cuts materials of different shape, size, and thickness while saving time and providing an excellent finish.

Contract Waterjet Cutting

At Anpllocnc, our team of experts is here to provide exceptional customer service to help with any part design, simple or complex. Our waterjet cutting machine is capable of cutting intricate parts from steel plate. Whether you are an entrepreneur with big ideas or a manufacturer that needs prototype parts, our team is ready to convert your concept into useable parts. We offer a cost-effect waterjet cutting service that fits your budget, with 100% traceable and ISO 9001:2015 certified quality.

We provide Industrial Waterjet Cutting Services. We often figure out how to cut that difficult part that others cannot figure out. Many times the solution for those extremely challenging parts is developing the tooling to enable the waterjet to cut it effectively.

When you give us a waterjet cutting project, it is not perceived as an afterthought, IT IS OUR ONLY THOUGHT! Your project is our top priority, and we make sure it is done correctly, most efficiently, with on time delivery.

Why Use Waterjet Cutting For Your Parts?

Waterjet cutting does not warp or alter the structure of the material being cut, as a laser or more traditional cutting tool sometimes does. It is also is capable of very fine and complicated shapes. Additionally, a waterjet’s precision cuts do not require sanding or grinding, and it produces no byproducts that might harm human operators or the environment — unlike laser cutting and plasma cutting. The water can also be recycled, reducing waste and cost while increasing energy efficiency.

CNC waterjet cutters can be used on almost any material, and are easily adjusted from pure water cutting to abrasive water cutting. This makes them an adaptable tool for many industries.

Cutting Capabilities And Eligible Materials

| Alloy Steel | Aluminum | Brass | Bronze | CR Steel | Copper | |

|---|---|---|---|---|---|---|

| Alloys | 4130, 4340 | 1100, 2024, 3003, 5005, 5052, 5086, 6061, 7050, 7075, MIC-6 | 260, 280, 353, 464 | 220, 510, 655 | A366/1008 | 101, 110 |

| Sheet/Plate Thicknesses | Up to 4″ | Up to 6″ | Up to 6″ | Up to 4″ | Up to 4″ | Up to 6″ |

| HR Steel | Nickel | Nickel Silver | Stainless | Titanium | Zinc | |

| Alloys | A36, A569/ASTM A1011, A653 Galv., A606/A588A Weathering | 200, 400, 600, 625, 718, A286, C276 | 770 | 15-5, 17-4, 17-7, 301, 302, 304, 310, 316, 321, 347, 410, 430 | Grade 2, 6AL-4V | EN 988 |

| Sheet/Plate Thicknesses | Up to 4″ | Up to 4″ | Up to 6″ | Up to 4″ | Up to 4″ | Up to 1/16″ |

We accept .dxf and .pdf drawing formats for custom quotes.

Benefits Of Our Services

Simplify your process

Let us handle one-off custom projects, large productions runs or component modifications

Eliminate waste

Eliminate wasted materials with our accurate and reliable high-volume custom cutting services

Reduce costs

Reduce overhead costs by delegating your precision cutting needs to our waterjetting experts

Contact Anpllocnc

Get a Quote Today for Your Water Jet Cutting Project

Our experts are ready to talk to you about your water jet cutting part. Get started today with an online quote.

Cutting Techniques Summary And How Water Jet Cutting Compares

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: EXPEDITE options available.

Custom Waterjet Cutting Benefits

- Abrasive waterjet cutting is up to four times faster than conventional waterjet cutting

- Precision cutting can hold tolerances, up to +/- 0.005″

- Waterjet cutting produces a finished edge cut, reducing secondary finishing, and providing the best cost-per-part cutting compared to any other cutting solution

- Versatile cutting of a wide variety of materials reducing secondary finish machining

- Waterjet cutting does not generate heat, so no burning or melting

- Parts can be stacked with precision cutting from layer-to-layer, which further reduces part cost

- Close nesting of parts reduces scrap and lowers the cost of each part

- Precision CAD cut capabilities support the accurate cutting of complex shapes from material up to 9” thick

Waterjet Cutter General Tolerances

| Description | General Tolerance |

|---|---|

Distance Dimensions | For features of size (Length, width, diameter) and location (position, concentricity, symmetry) +/- 0.030” is typical. Material length and thickness may affect tolerances. |

Thickness Dimension | Thickness tolerances are determined by the material blank. |

Minimum Recommend Part Size | 3.000″ |

Minimum Feature Size | 2X material thickness with a minimum of 0.125″ |

Kerf (slit size) | Approximately 0.062″ |

Edge Condition | Waterjet parts will have a vertical striation on the edges and may show a slight taper. |

Please check out Anpllocnc’s Manufacturing Standardsfor more information on tolerances per process. Unless we have agreed to other tolerances in your Quote, we will work to achieve and hold the tolerances noted.

Why Anpllocnc?

Anpllocnc proudly offers waterjet cutting services, and we are capable of providing steel plate cut to your exact specifications. All inventory is 100% traceable and all waterjet cut parts are produced following our ISO 9001:2015 certified quality program. Anpllocnc can perform material takeoffs from your drawings, reproduce your parts using SolidWorks, nest your project on our plate inventory, and then perform high-quality burning and beveling. Our company is determined to exceed expectations, industry standards in lead times and product offerings. For more information about our waterjet cutting service, contact us today to discuss your design needs.

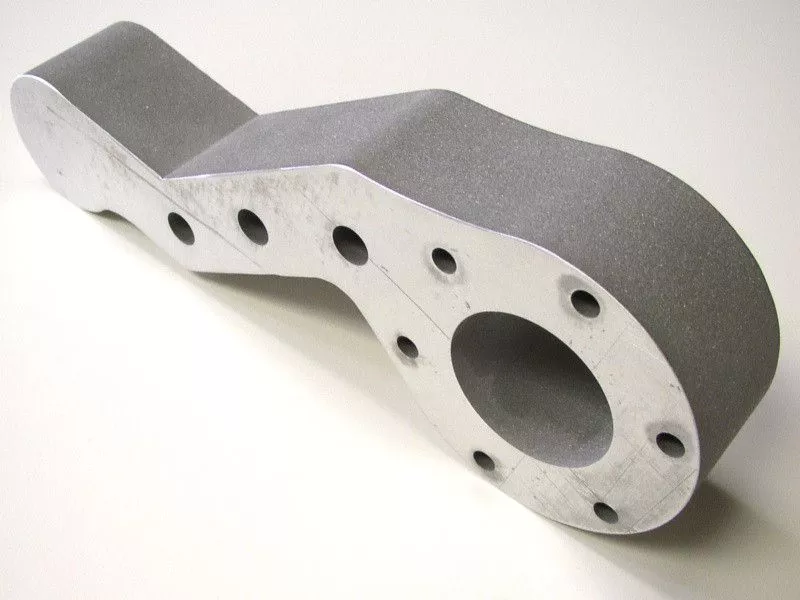

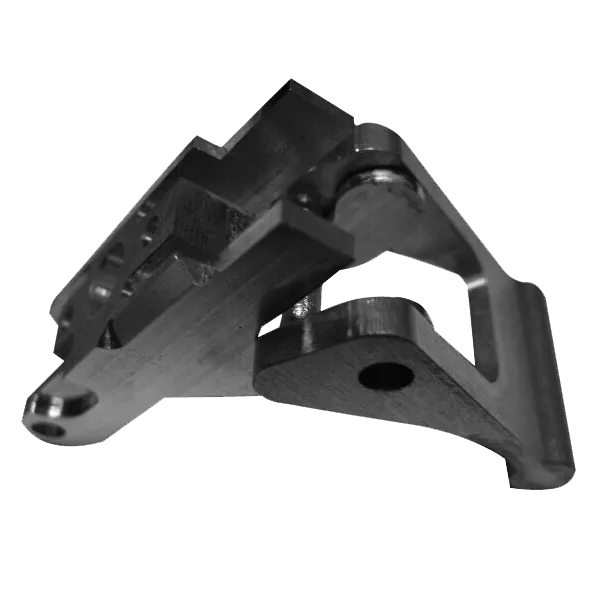

High Quality Waterjet Cut Parts

Waterjet Cutting Resources For Engineers

No posts found!

Contact Anpllocnc

Custom Metal Fabrication with Waterjet Cutting at Anpllocnc

While waterjet cutting may be the best method for your component, Anpllocnc recognizes that your project’s needs are specific. That’s why our team is happy to review your project’s design and determine the best method — whether it’s waterjet cutting or laser cutting, or another metal forming service that we offer.

We offer a variety of testing and inspection procedures (e.g., surface and dimensional, ultrasonic testing, visual inspection, etc.) to ensure the quality and integrity of your metal component. We also offer value-added services, such as bending, boring, centerless grinding, double disc, grinding, drilling, forming, heat treating, rolling, stamping, and trepanning, to help you produce a fully finished part.

To find out how our waterjet cutting or laser cutting services can help with your next project, contact us today, or request a quote online.