Laser Tube Cutting Services

Precise, high-quality tube laser cutting service with rapid lead times and competitive prices.No matter how large or small, simple, or complex your cutting requirements, your project is in safe hands with Anpllocnc Tube laser cutting – also known as 3D cutting – is proven to reduce material costs, increase downstream productivity, and deliver a competitive edge. Take advantage of our multi-axis tube lasers to open new design possibilities and optimise parts for highly efficient manufacturing.

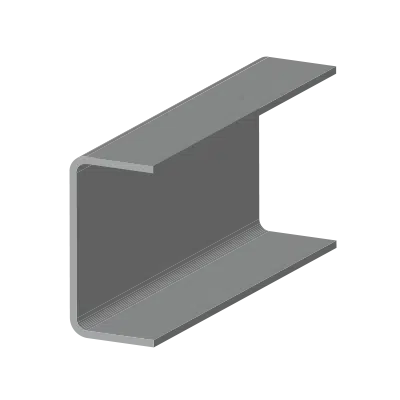

PFC Channel

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

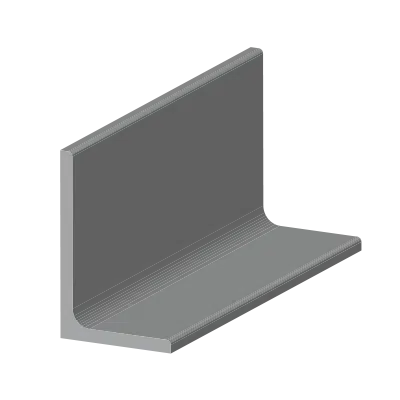

RSA Angle

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 254 x 254mm |

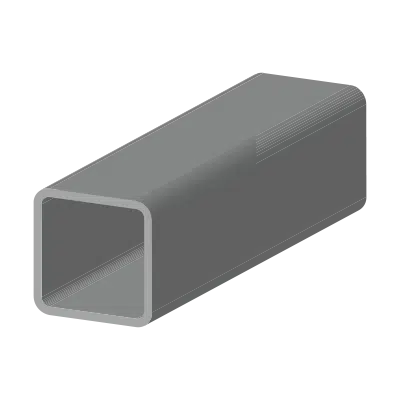

Rectangular & Square Tubes

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 300 x 300mm |

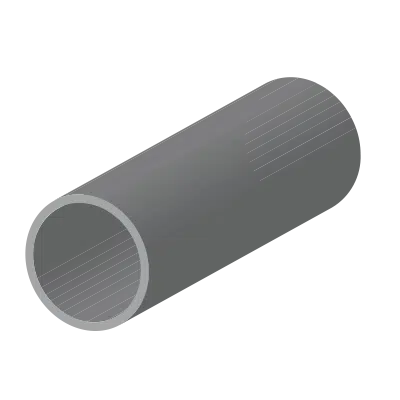

Round Tube & Pipe

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10mm | 406.4mm |

Universal Beams

| Minimum (mm) | Maximum (mm) |

|---|---|

| 10 x 10mm | 203 x 203mm |

A team you can trust

For OEMs, a substandard part can negatively impact the performance, safety and reliability of the final product. Receive parts that fit the intended purpose, form, and function with Anpllocnc’s CNC tube laser cutting services. We are a China-based manufacturing solutions provider specializing in turnkey laser cutting services for OEMs and their supply chain partners. For a full production run, we can meet your needs exactly.

Laser Tube Cutting parts online quote

We can provide a wide range of laser tube cutting services for metallic and non-metallic materials (plastics, specialty materials, etc.). The types of lasers used include fiber lasers or CO2 lasers, depending on the material and application, allowing for very tight tolerances (plus or minus 0.005 inches or less) and the ability to cut wall thicknesses up to 3/16 inches. It’s easy to start a quote for your next laser tube cutting project using Anpllocnc’s online quoting engine. Additionally, our project managers and experts personally review and manually quote each laser tube cutting project to ensure we meet your unique needs while providing a fast, easy manufacturing experience.

Tube Laser Cutting Capabilities

- Elimination of stack up tolerances inherent in multiple operations

- Shapes supported by our laser tube cutting systems include Round, Oval, Square, Rectangular, and other custom closed profiles.

- Other open shapes such as Angle, “C” channels, and other structural shapes maybe supported please consult with Anpllocnc for more information.

- Our laser tube cutting equipment accommodates up to 29.5’ tubes weighing a maximum of 500 lbs.

- Self-centering chucking jaws do not need to be changed, and rollers which guide tubes through the laser tube cutting machine automatically adjusting to their diameter

- Reliable automated seam detection

- Virtually unlimited cutting configurations

- No tooling required with our tube cutting machines

- Smaller lot sizes and processing of a wide variety of metal alloys

- Our laser tube cutting equipment accommodates up to 29.5’ tubes weighing a maximum of 500 lbs.

- Our advanced laser tube cutting systems reduce fixture costs and increase productivity with the utilization of plug in and/or folded joint connections

- Stainless tube cutting and fabrication

- Virtually unlimited cutting configurations

- No tooling required with our tube cutting machines

Tube, Pipe, Angle, Box, and Channel Materials

- Carbon Steel

- Stainless Steel

- Aluminum

- Copper

- Bronze

- Brass

- Other Alloys

Industries served

- Agricultural

- All-terrain Vehicles (ATVs)

- Appliances

- Architectural

- Automotive

- Furniture

- Health and Fitness

- Heating and AC

- Heavy Equipment

- Lawn and Garden

- Motorcycles

- Petroleum and Mining

- Retail & Display

- Rollover Protection Structure (ROPS)

- Snowmobiles, Solar Energ

What is Laser Tube Machining?

Laser tube cutting is a process in which a laser beam is focused on the outside surface of a metal tube to perform a cutting operation. The tube is fed in various patterns beneath the focused laser beam, where the tube wall is melted through. In medical applications with smaller tube diameters, the laser’s beam width is approximately .10 mm (.004”). Our machines are equipped with fiber lasers.

In the case of most laser machines, the laser is stationary and aimed directly toward the center of the tube. The tube that is being cut is fed through a stationary guide bushing—a “slip-fit” mechanism which stabilizes the tube while keeping it aligned and at a proper distance under the focused laser beam. Behind the guide bushing, the tube is held firmly by a programmable 360-degree indexing collet. This device can rotate the tube and has the ability to simultaneously push and pull the tube axially through the guide bushing. The CNC controller delivers the programmed instructions to these mechanisms, which cut out the desired shapes and configurations from the tube.

Precision Laser Tube Cutting - The Anpllocnc Advantage

- Higher quality

- Dimensional control, repeatability, accuracy

- Design changes without tooling & no part-specific tooling required

- Intricate design features available; not possible on traditional equipment

- Decrease total lead time

- Lower total costs & reduced labor

- World class material traceability

- Surface critical capability

Advanced Tube Laser Cutting

Part optimisation is reaching unprecedented levels of efficiency thanks to the availability of 6-axis 3D cutting. The ubiquitous nature of tubes and profiles ensure a broad scope of opportunity to design more profitably. The ability to reduce materials, processes such as welding, and improve assembly times, are revealing routes to new markets for manufacturers.

Cutting, welding, milling and deburring processes add cost to a project. Access to a 3D laser tube cutting machine means designers have the ability to reduce processes for faster lead times and lower costs. Average cost reduction is around 50% with 85% cost reductions common.

Need a hand? Maximise efficiency through design, with Anpllocnc’s in-house design service. We can fully optimise part design for efficient manufacturing and downstream assembly.

Our in-house Cutting Services

- Tube laser cutting (3D cutting)

- Large and open section cutting

- 2D flatbed laser cutting

- Smart design service

- Flow drilling

- Waterjet cutting

- Flame cutting

- Weld preps

- Profile bending

Commitment to quality

Anpllocnc offers a vertically integrated turnkey manufacturing process, including extensive in-house second- and third-step processing capabilities. Our fully automatic tube laser equipment represents the latest technology. Each facility is ISO 9001:2015 certified, providing significant capacity and manufacturing redundancy. We use the Value Analysis/Value Engineering (VA/VE) process to practice collaboration on new and existing products. This allows us to validate the manufacturing process before production, saving development time, reducing costs and delivering on time every time.

Create your own

Would you like to hit the ground running right away?

Let the experienced pipe laser cutting experts work for you. Whether you need rapid prototyping or high-volume parts – we’ll support your project.