China factory custom laser cut anodized aluminum CNC machined parts...

Read MoreLaser Cutting Service

We understand that custom manufacturing requires precision and accuracy. That’s why at Anpllocnc, we offer the most advanced laser cutting technology to maximize uptime while keeping costs to a minimum. Our CAD/CAM capabilities and machines are equipped with automation – so no matter what shape or size you need, we have the capacity to deliver an exact product with unbeatable speed and efficiency.

- Free quotation with DFM review within 1 day

- Lead time as fast as 3-5 days

- ISO 9001:2015 certificated

Anpllocnc Is Equipped to Handle Your Toughest Laser Cutting Jobs

Anpllocnc is a fully equipped, industrial laser cutting service center with the most skilled laser-machine technicians in the China. Anpllocnc’s staff are experienced and capable of laser cutting to the demands of high reliability and repeatable aerospace and medical standards, including precision laser cutting of microelectronics and medical devices. Moreover, Anpllocnc provides fast turnaround on a wide range of in-stock materials, including aluminum nitride (AlN) ceramic substrate materials, frozen epoxies, EMI and microwave absorbers, stainless steel tubes and adhesives.

Our team is equipped with state-of-the art, computer-aided drafting and computer-aided modeling (CAD/CAM) software for highly accurate design and laser cutting tolerances machine control. Anpllocnc leverages these tools alongside micro-positioning tables, multiple-beam systems, and statistical processing controls to deliver extremely repeatable and exact laser cut tolerances from part to part and job to job. Also, Anpllocnc is willing to go above and beyond for their customers, and has even customized special laser systems, fabricated new rotary laser cutting, drilling, and marking machines, and developed advanced analysis tools to ensure part quality.

Anpllocnc is home to more than 26 low-power, medium-power, and high-power CO2, YAG, and diode/fiber lasers, and we employ highly skilled and experienced laser-machining professionals to optimize the operation of every machine. Our laser-cutting machines can achieve micron-level cutting precision of thick sheets of high-strength stainless steel down to extremely delicate, intricate, detailed, precise cuts on thin foils, fabrics and a wide variety of other materials.

Our Laser Cutting Equipment

- Mazak Tube Laser – Fabri Gear

- Trumpf TruLaser 3530

- Trumpf TruMatic L-6030

- Bystar 4020 6KW CO2

- Bysprint 4020 6KW Fiber

- Bysmart 3015 3KW Fiber

- LT5 – 4KW 24′

- LT8 – 4KW 28′

Why Choose Laser Cutting?

Laser cutting is particularly effective and presents strong advantages in many areas where rapid production or the creation of quick prototypes is essential, It’s easy to cut accurately in many materials where traditional manufacturing methods are inefficient. Limitations and constraints imposed by traditional manufacturing processes are removed through Laser Cutting, which allows freedom of design and quantities.

- Ability to handle complex jobs. There is no job that is too complicated or detailed for laser cutting machines to perform. Precision laser cutting creates minimal distortion and warping and delivers unrivaled tolerance levels on even the most complex geometries.

- Low lead time and costs. Laser cutting doesn’t require any custom-built or specially modified tooling, which significantly reduces lead times and costs compared to other cutting methods. It also doesn’t have any physical cutting surfaces that wear out and need to be replaced. Since all that’s required is the laser cutter and the design, overall costs are greatly reduced.

- Low power consumption. Even when used to cut extremely thick materials, laser cutters require low amounts of energy. This is primarily because, unlike other cutting tools, laser cutters have no moving parts. In most situations, laser cutters require less than 10 kW of energy, which decreases running costs and has a lower environmental impact than other cutting tools.

- Versatility. Besides cutting, laser cutting technology can perform a variety of other tasks, including marking, drilling, and engraving, without the need to switch or replace tooling. Precision laser cutting is also unique in that it is suitable for a wide range of materials, including not only metals but also wood, plastic, and more.

- Flexibility. Laser cutting does not require switching or changing tools between cuts. The same setup can cut a variety of shapes within the same material thickness, regardless of how complex the cuts are.

- Precision. In comparison to other thermal cutting methods, the precision of laser cutting is second to none. With an accuracy of +/-0.1 mm, highly precise cuts can be made without requiring after-treatment. In most cases, tolerances are typically between 0.003 mm and 0.006 mm, far outperforming other cutting techniques.

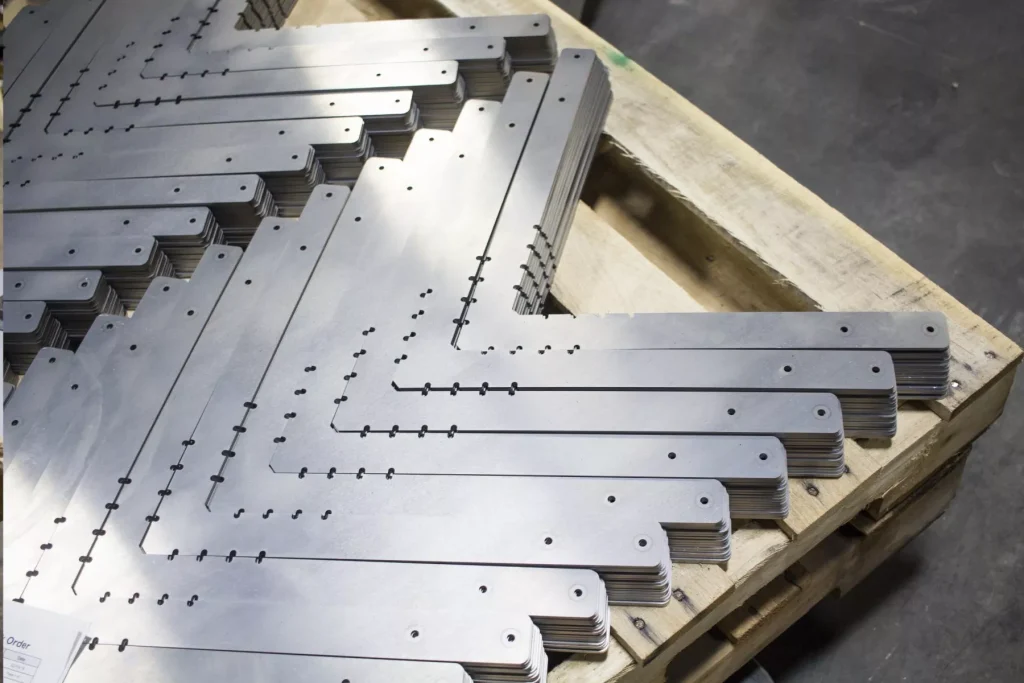

Sheet Metal Laser Cutting Parts

For many years, Anpllocnc’s laser cutting service has covered a wide range of applications for many industries. Below are some of our previous laser cutting projects.

contact us today

Request A Quote For Laser Cutting Services

No matter the size of your order, from prototypes to high volume production runs, your medical enclosures, prescription security boxes and vending machine component parts will be laser cut quickly and cost-effectively. Everything we ship meets or exceeds all the top industry standards including ISO 9001:2008 and AS-9000.

You can get an instant quote from a 3D CAD file (file formats include: STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT files) through our Instant Quoting Engine.

Laser Cutting Capabilities

Fiber & CO2

12,000 W

19 Position material tower with automated material retrieval & parts storage

Complete Lights Out Manufacturing Capabilities

Up to 120″

Up to 60″

- Up to 1.18″ Aluminum

- Up to 1.18″ Stainless Steel

- UP to 0.47″ Copper

- Up to 1.18 Carbon Steel

- Maximum Thickness Depended on Material

(Please refer to the sheet thickness table below)

±0.005″

- AS9100 Revision C Certified (#12912)

- Conflict Materials Compliant

- DFAR Compliant

- ISO 9001:2008 Certified (#12912)

- ITAR Registered (M23878)

- Reach Compliant

- RoHs Compliant

- SVHC Compliant

- Aluminum (All Alloys)

- Armor Plate

- Brass

- Bronze

- Copper

- Expanded MetalGalvanized (G30 – G90)

- Galvannealed (G30 – G90)

- Perforated Metal

- Prepainted Material

- Stainless Steel (2B, #3 & #8)

- Steel (CRS, HRPO & HRS)

- CMM Equipment

- Deltronic Pins

- Digital Height Gages

- Digital Microscope

- Digital Micrometers & Calipers

- Hardness TestersMaster Gauge Blocks

- Optical Comparators

- Pull Testers

- Slipstick

- Virtek (Laser Scanner)

- Deburring

- Glass Bead Blasting

- Graining (Brushed Finish)

- Polishing

- Sand Blasting

- Vibratory Tumbling

- Anodizing

- Bright Dip

- Standard (Multiple Colors)

- Hard Coat

- Barrel Plating

- Black Chrome

- Black Oxide

- Bright Nickel

- Brush Nickel

- Cadmium

- Chromate (Clear or Yellow)(Also known as Iridite or Chem Film)

- Chrome

- Copper

- Etching

- Electroless Nickel

- Electropolish

- Gold

- Hard Chrome

- Passivation (Nitric of Citric)

- Phosphate (Pretreat)

- Rhodium

- Silver

- Tin

- Zinc (Clear, Yellow or Black)

- Hexavalent

- Trivalent (RoHs Compliant)

- Zinc Cobalt

Plating Certified to AS9100, ISO, ITAR & NADCAP

- Dielectric Paint

- E-coating

- Powder Coating

- PTFE

- Wet Paint

- Assembly

- Engraving

- Heat Treating

- Ink Fill

- Kitting

- Silk Screening

- Blanket Orders Accepted

- High Volume

- Low Volume

- Prototypes

- Over 5,000 Parts Typical

- 1-2 Week Expedited Service Available

- 4-6 Weeks Typical

- Specific Lead Time Quoted on a Job by Job Basis

- Autodesk Inventor (Preferred)

- Any .STP File

- CADKEY

- CATIA

- NX (Unigraphics)

- Parasolid

- Pro/E

- Solid Edge

- SolidWorks (Preferred)

Materials And Thicknesses For Laser Cut Parts

We offer the following metal materials for custom laser cut parts. Note that based on material thickness, maximum part size will vary.

| Material | Grade | Thicknesses Available |

| Aluminum |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Steel |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Stainless Steel |

|

0.025 in. – 0.250 in. (0.635mm – 6.35mm) |

| Copper |

|

0.025 in – 0.125 in. (0.635mm – 3.175) |

| Brass |

|

0.025 in. – 0.125 in. (0.635mm – 3.175) |

Why You Can Trust Anpllocnc

No matter what your company manufactures, from precision lab equipment to rustic crafts or anything in between, we can help you design, prototype and cut the finished pieces you need. We stock many different sizes and types of sheet metal, and thanks to our full suite of fabrication equipment we can form, weld and finish just about any type of component.

Once we’ve produced your run, we can provide quality control using our laser modeling and measurement equipment. By scanning finished components and comparing the final dimensions to our engineering drawings, we can make sure that each piece we produce falls within the most precise tolerances. We can even use our laser scanning equipment to create a reverse-engineered drawing of any metal part that you may need to have produced.

At Anpllocnc, we’re constantly expanding and improving upon our equipment and our methods to better serve our customers with high quality, affordable parts. So if you’re looking for a cutting partner that can deliver what you need on time and on budget, please contact us today. We look forward to helping with your next project.

What Is Laser Cutting?

Laser cutting is a form of custom manufacturing that is used in many industries, but is particularly popular with signage. The process involves using a high powered laser that cuts through dozens of different types of materials using a computer generated 2D vector design.

The laser itself is created by stimulating lasing material with electricity until it achieves the needed heat to burn or melt through the material. Fiber optics direct the laser in a focused point that can be applied to the substrate.

The design for the laser to cut is created first in a CAD program. Design vectors are then relayed to the CNC controller that operates the laser through G-code coordinate instructions, translated into readable code by a specialized CAM software. This provides precision markers for the laser to cut. The depth and speed of each cut is controlled by the operator.

Laser Cutting For Various Applications

Many industries worldwide are gradually transitioning to laser cutting technology because it provides additional benefits such as precision, tight tolerance, flexibility, clean finish, enhanced productivity, and design complexity. Whether for prototype or full-scale manufacturing, switching to laser cutting saves time and money.

FAQ

You can send us your laser ready file or if you do not have file we can design one for you! To obtain a quote e-mail [email protected] your design details. In your e-mail include the size of your design, quantity, and material you want. If you have a laser ready file please include that in the e-mail.

Material cost and laser time play a factor into configuring your quote. Keep in mind detailed shapes, will take longer to cut than a plain circle/square, adding engraving in your design will also increase the laser time. The type of material used also impacts the total laser time. For example 1/4 inch acrylic takes longer to cut than 1/8.

We prefer you send us an Adobe file or SVG file. Make sure your design is the size you want it cut, as we will not modify your file. In your file you will want to make all the lines you want cut one color (black) and all the lines you want engraved another color (red). The max size we can cut is 28″x40″, so please make sure your design is no larger than that.

After you e-mail us we will review your laser ready file. We will then send the file to our laser software to get an idea on how long your file will take to cut/engrave. If you do not have a file our team will work on creating one for you. Please note if you do not have a file or your file is not laser ready a “Design Fee” will be added to your quote.

We currently offer to cut down our 12×19 sheets into smaller sizes to fit different machine beds or project needs. This material cut-fee is different than our laser cutting services. We charge $1.00 per sheet maximum $10.00 charge. We do all our custom cuttings on Friday/Satuday. If you wish to have your sheets cut down, please include this item in your cart and follow the instructions in the item description.

Explore Related Resources

Contact Anpllocnc

Choose Anpllocnc for Custom Laser Cutting Services

Anpllocnc is an ISO 9001:2015 certified company, and we are prepared to meet any specification for every application. Through custom laser cutting and other services, we bring your designs to life through prototype parts with FAIRs available upon request, ensuring that you are completely satisfied with your results before moving on to production and delivery. We have the hands-on expertise and industry knowledge to complete production runs of any size.

Our team is dedicated to fabricating your parts faster, easier, and for a lower price without impacting quality or performance. Contact us to learn more about how our china manufactured products and converting services can support you and your business. Request a quote to begin your order.