Compared with 3D printing, the biggest advantage of CNC plastic...

Read MoreRapid Prototyping Service & Custom Manufacturing

Accelerate your research process by adding our Expert Team to yours. We provide cost-effective design,cnc machining services and sheet metal fabrication service.

- Parts delivered in as fast as days

- Fast alterations from designs to production

- An array of online rapid prototyping processes

- Various combinations of materials and surface finishes

Anpllocnc Is The Right Choice For Your Rapid Prototyping And Manufacturing Needs

At Anpllocnc we specialise in Rapid Prototype Manufacturing Services, to customers across the world. Our CNC machining service,Sheet Metal Fabrication services, providing everything from prototype to production manufacturing solutions.

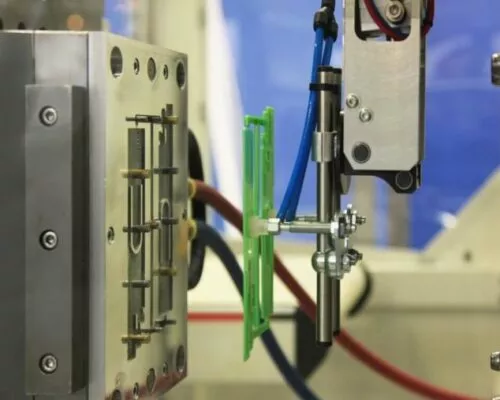

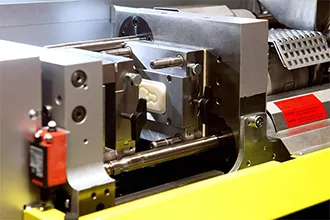

In the fast-paced world of new product innovation, you need a partner you can rely on for rapid injection molding, rapid prototypes, and low-volume production. We supply prototype manufacturing services that can deliver with the speed and quality your project deserves.

At Anpllocnc, we make things for you. Rapid products and parts delivered fast. Rapid tooling that delivers more parts than you are used to. First class prototypes that look like production parts. Fully functional parts that act like production parts. Flexible project solutions that fit your specific project requirements. Our MOQ starts at 1 for prototypes and typically goes up to 100,000 parts (plastic, metal, composites), anywhere in this range is what we would consider low-volume manufacturing.

From Rapid Prototyping To Production

Rapid Prototyping

From Anpllocnc, you can get your prototypes done in days, which allows you to verify the design fast.

- Instant quotes

- Instant DFM feedback

- Excellent quality

- Fast Delivery

Low Volume Manufacturing

Rapid tooling is a cost-efficient way to bridge the gap between prototyping and final production. Launch your products to the market fast.

- Lower cost

- Production-level quality

- Fast delivery

- Test out the market before investment

On-Demand Production

For production projects, our engineering team will support you to achieve the best products in terms of quality and cost.

- Experienced engineers for DFM optimization

- A professional project manager working in your time zone

- First Article Inspection

- Guaranteed consistent quality

Anpllocnc's Rapid Prototyping Service Type

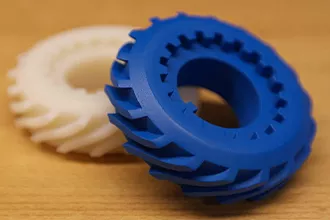

Anpllocnc can guarantee rapid prototyping and manufacturing and help you refine your prototype design. We offer a full range of material testing and surface finish testing. So you can decide how to move forward with your project and make the best decisions. Rapid prototyping is a product development method that allows the production and iteration of product components for evaluation and testing.

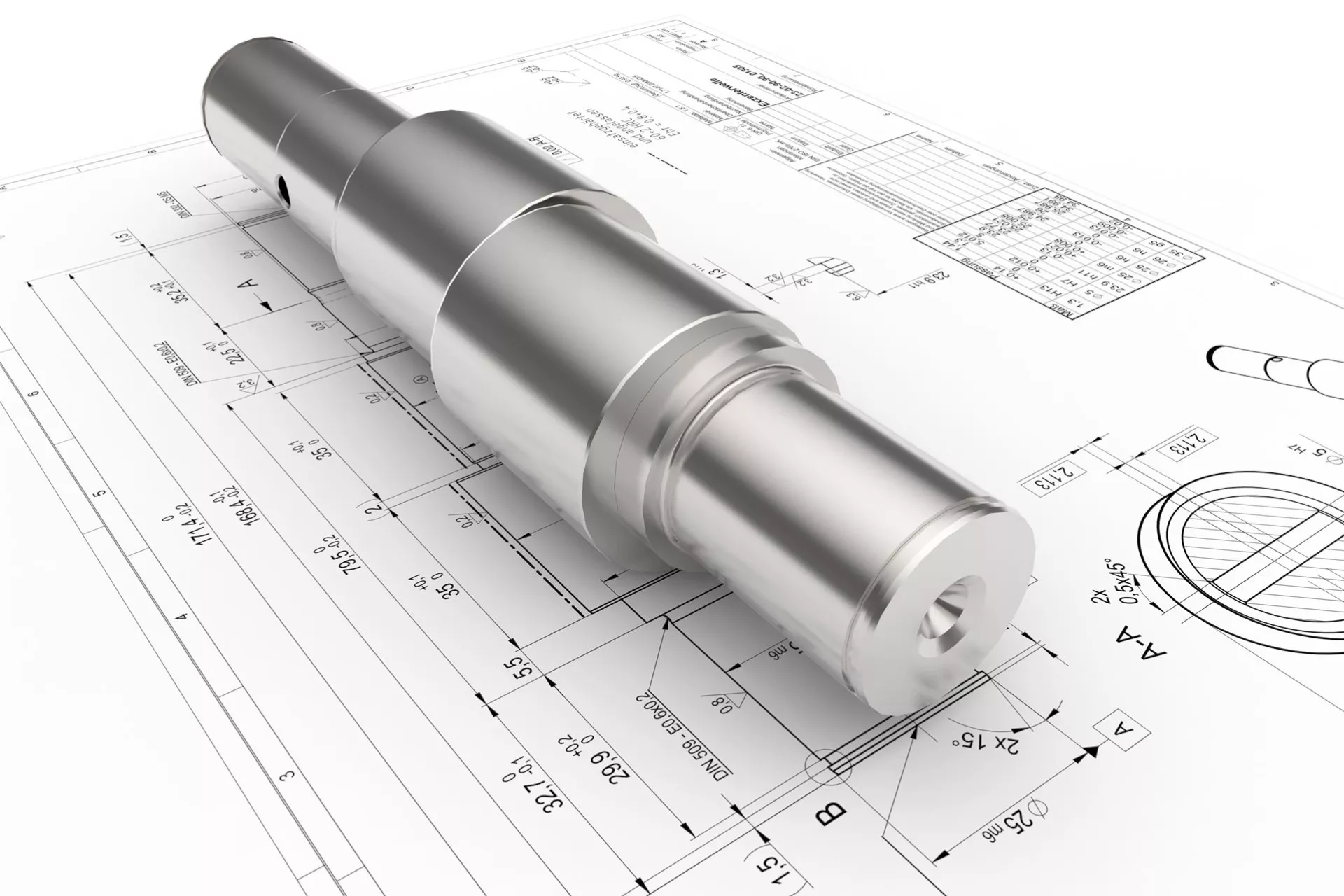

CNC Machining

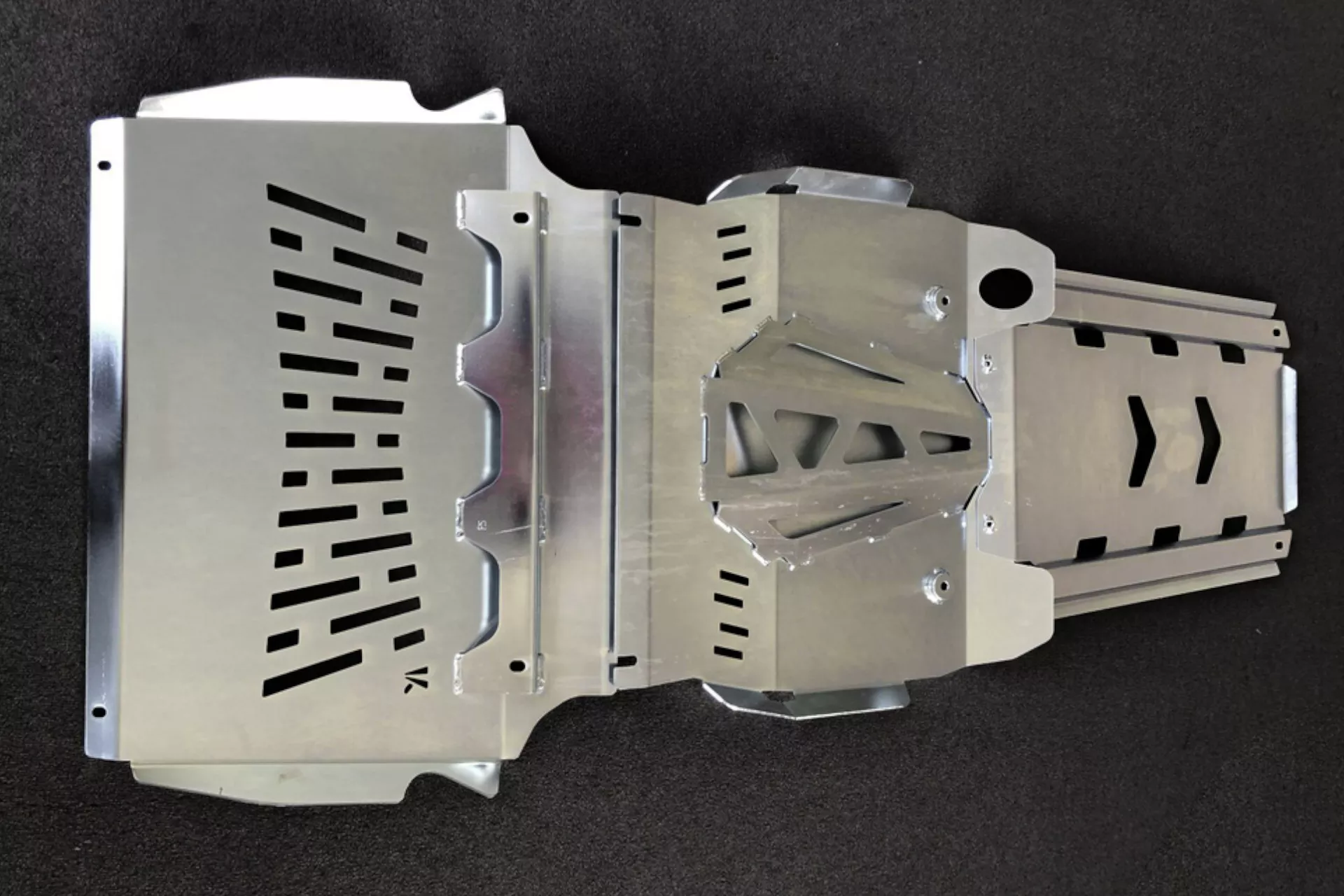

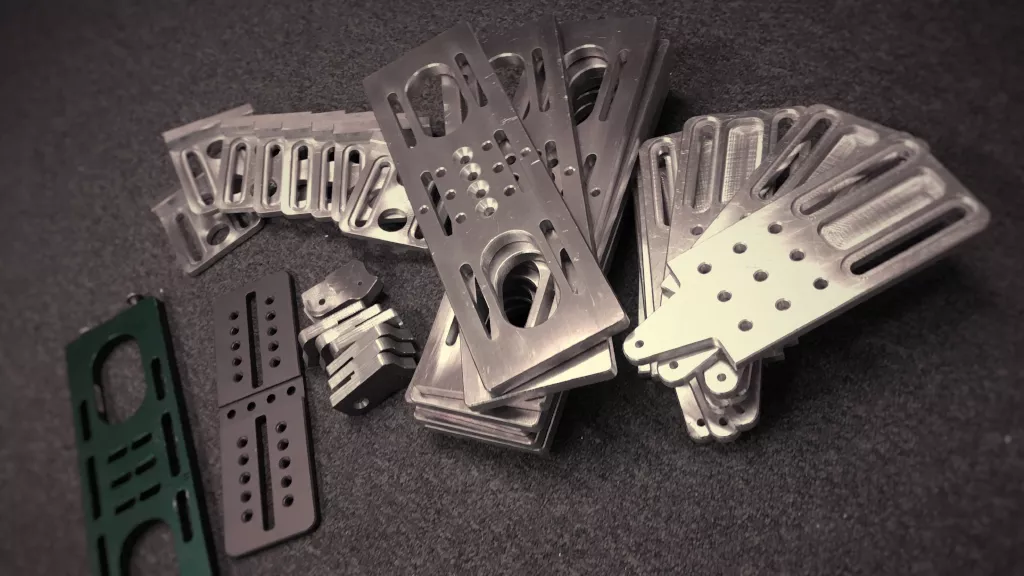

Sheet Metal Fabrication

3D Printing

Injection Molding

Rapid Prototyping Capabilities

- Functional Prototypes

- Scale Models

- Short Run Production

- Visual Prototypes

- CNC Machining

- Sheet Metal Fabrication

- 3D Printing

- injection molding

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

- Up to 8 in.

- Up to 8 in.

- Up to 12 in.

- .007 in.

- ± .002 in.

- Automated Paint Line

- Water-Based Paints

- Water-Based Metallic Paints

- Parts Decorating

- Spatter Coating

- Texturing

- Plating

- Coating

- Powder Coating

- Pad Printing (Including Metallic)

- Assembly

- Packaging

- Shipping

- Warehousing

- Coordinate Measuring Machine (CMM)

- Video Probe Microscope

- Optical Comparators

- Micrometers

- Calipers

- Gage Blocks

- Leak

- Advanced Quality Planning

- Continual Quality Control

- Customer Specification

- Prototype to Large Scale Production

- 3 to 4 weeks

- In-House Customer Inventory Stocking

- Just In Time (JIT) Delivery

- Kanban

- ISO 9001:2015 Certified

- UL Certified

- FDA Certified

- SolidWorks

- STEP203 / STEP214 (STP)

- Unigraphics (PRT)

- Parametric Solid (SMT)

- IGES (IGS)

- AutoCAD (DWG, DXF)

- Kubotek KeyCreator

contact us

Get in touch with our rapid prototyping and manufacturing experts today

They can advise you on the best approach for your application.

From Rapid Prototyping To Production

We help startups and established brands manufacture prototypes and products that compete favorably in the global market. This is a testament to the quality and precision of our machines and a seasoned team of professionals working tirelessly to ensure your top-quality products get to the market as when due.

At Anpllo, we offer top-notch services encompassing all manufacturing aspects, from prototyping to production. Considering your ideal prototyping material, our rapid prototyping services include CNC rapid machining services and sheet fabrication. Our rapid prototyping and production services considerably cut the production cost for you while reducing the time to market. So please work with us today for all your prototyping to production needs.

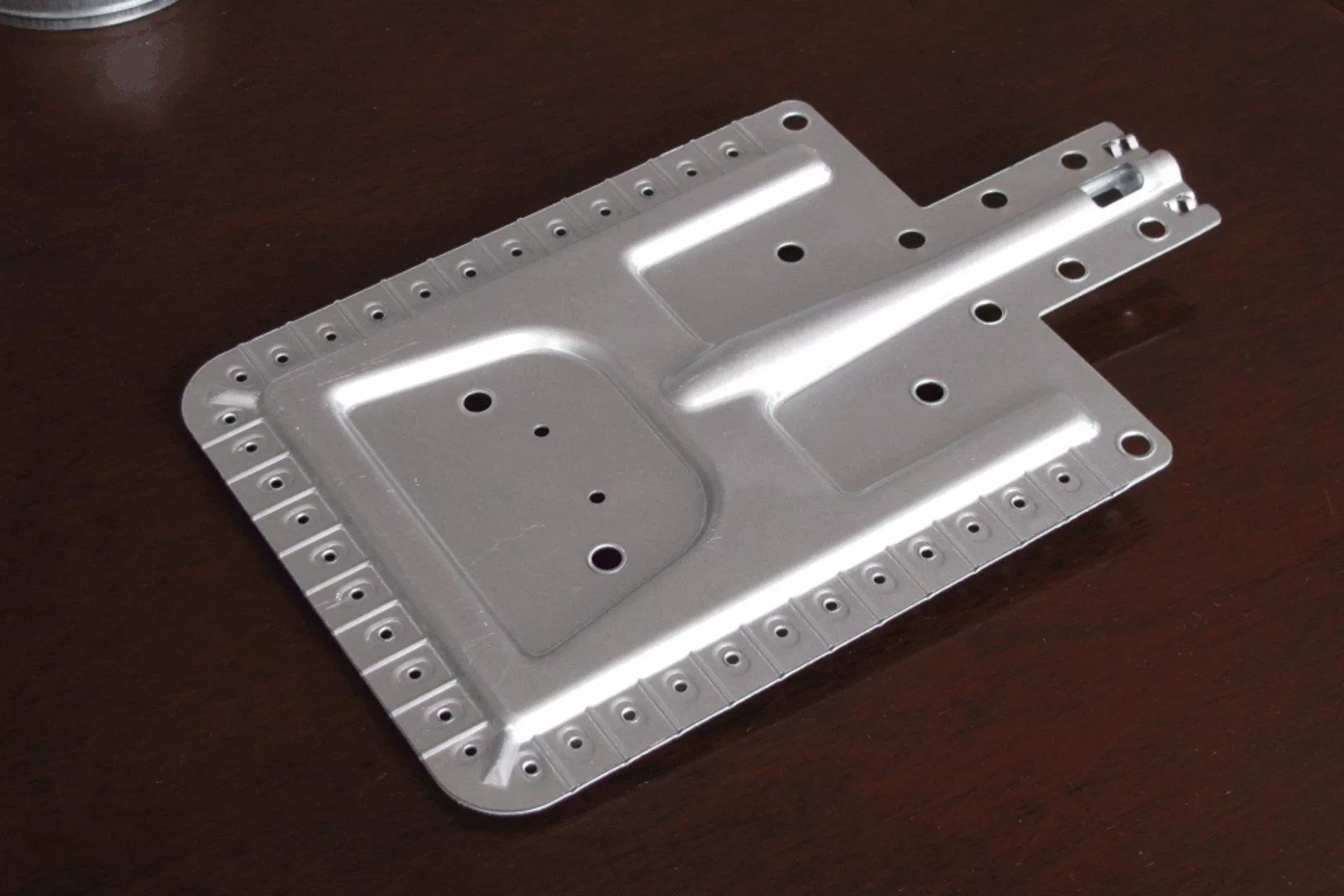

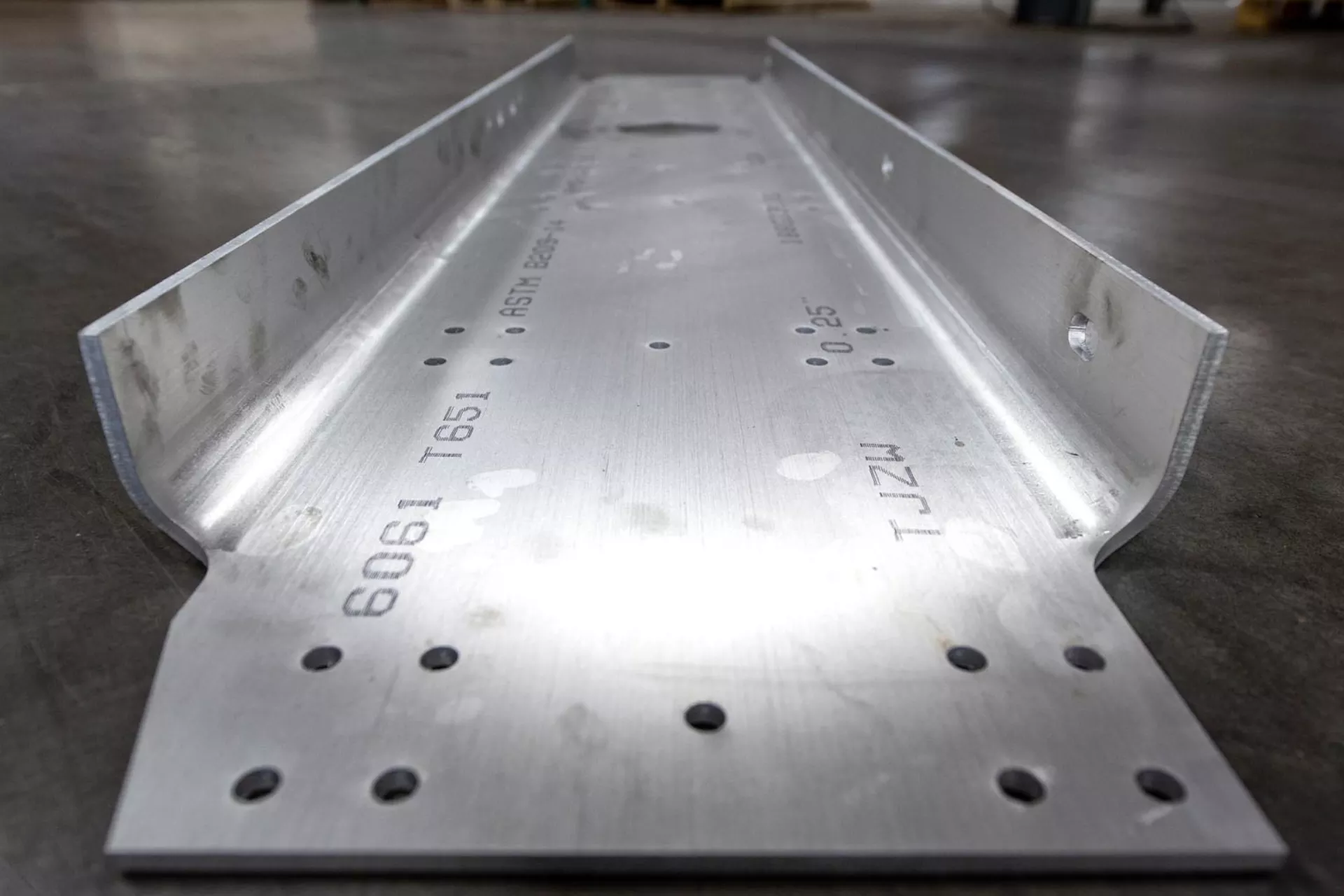

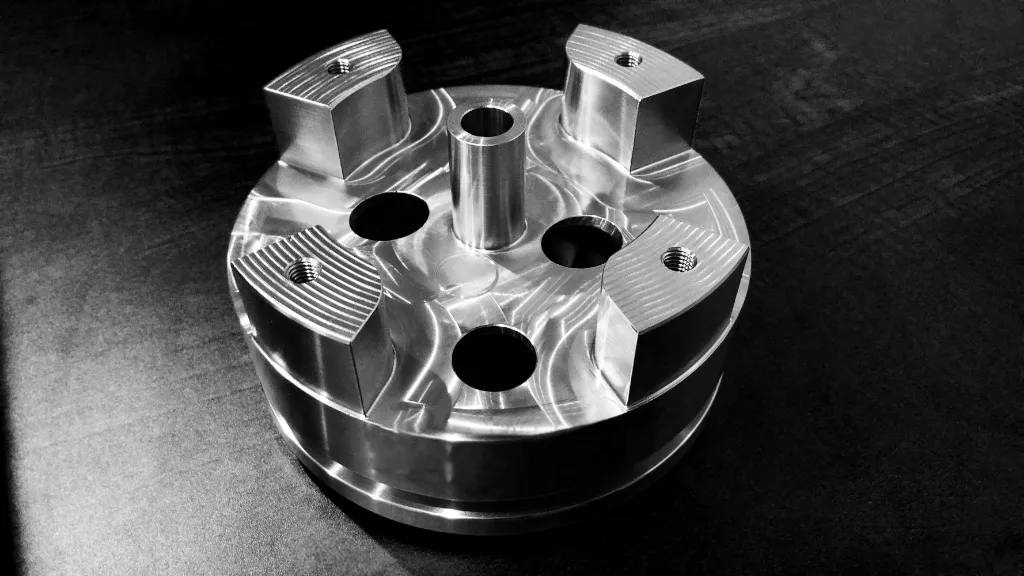

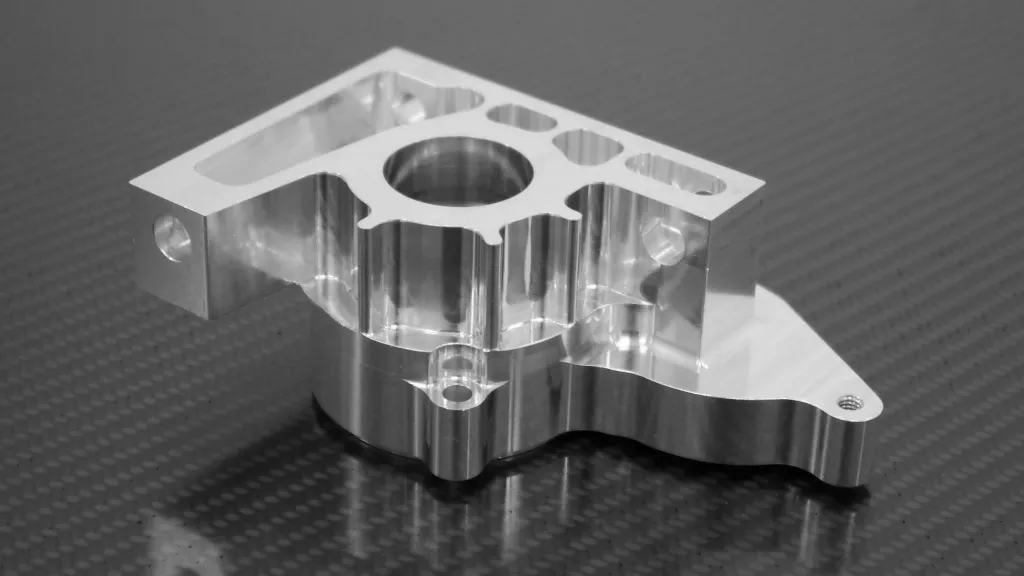

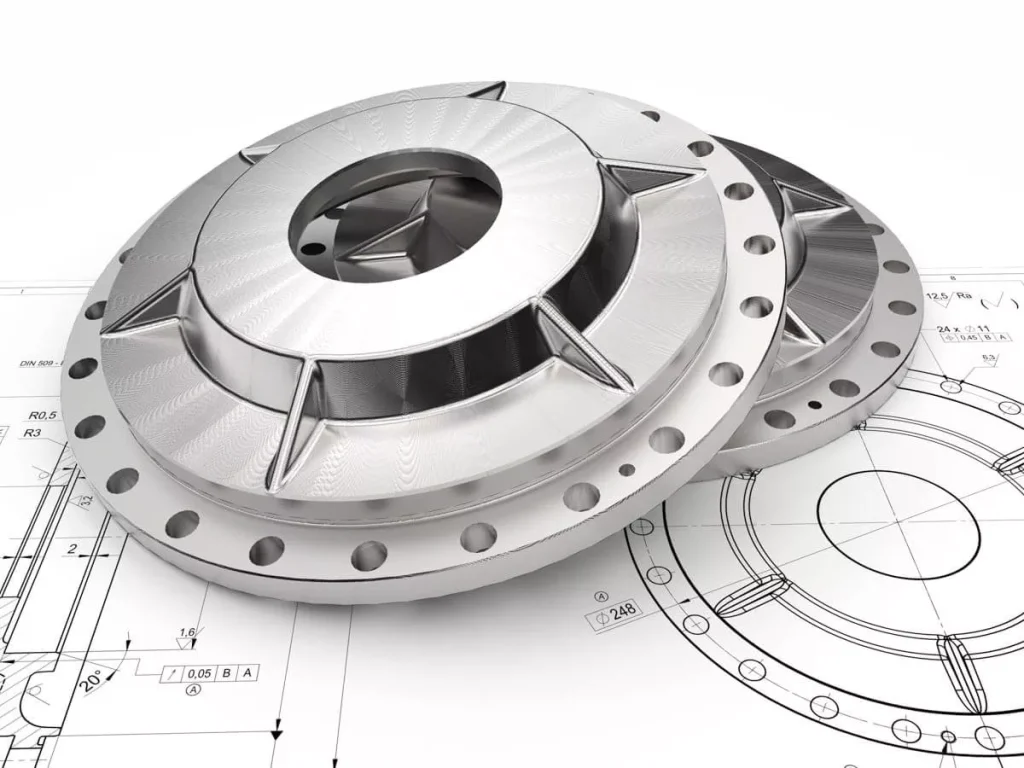

Gallery Of Rapid Prototyping Parts

We have produced prototypes for various industries, including medical, automotive, aerospace, and construction.

Why Do You Need Custom Rapid Prototyping Service

Custom Rapid Prototyping Advantages and Benefits You Need To Know:Custom rapid prototyping services are mainly used for the new product development, small-batch parts manufacturing, complex shape parts manufacturing, mold, and model design and manufacturing.

- Rapid prototyping services can reduce the manufacturing time of product models or molds, help you significantly shorten the development time of new products;

- Rapid prototyping design and manufacturing service will improve the design and production capacity of manufacturing complex parts, making the manufacture of complex models easily and possible;

- In Rapid prototyping process, you can find product molds design errors promptly, find mistakes and make changes earlier, and avoid a lot of losses caused by changing subsequent processes;

- Rapid prototype services support the implementation of synchronous projects, make the new product design, product evaluation, product sample manufacturing, and production preparation be carried out in parallel;

- Rapid prototyping and manufacturing service can reduce the cost of product development, design, and manufacturing a lot.

- Custom prototyping services can quickly achieve single-piece and small-batch production. Bring new products to the market considerably ahead of time.

contact us

Ready for Your Project with A Free Quote?

Types of Rapid Prototype

The rapid prototyping process is far-reaching, encompassing several materials, technologies, and industries. There are four different types of rapid prototypes.

| Concept Model |  |

This is one of the simplest types of prototypes. Also called a proof-of-concept prototype, engineers use the concept model to convey the basic idea of the design. Before use, this type of prototype undergoes multiple changes. |

| Display Prototype |  |

Engineers develop this type of prototype to make it look similar to the final product. Most times, functionality is not a factor considered under the display prototype as the focus is mainly on appearance. |

| Functional Prototype |  |

This prototype focuses on functionality and aims to enable engineers and designers to test the product to make modifications if any, for optimal functionality. The prototype developed here should behave the same way as the final product. |

| Pre-production prototype |  |

This is the last type of prototype developed before production. There are two major purposes of this type of prototype. First, to validate the process chosen by the manufacturer for mass production, and second, to ensure the manufactured part functions optimally. |

How To Choose The Right Rapid Prototyping Technique

The right prototyping method is the one that best fits your budget, the complexity of the part, what you want the prototype to do, and your development timeline. Better prototypes cost more money and take longer to make, but they also more faithfully represent the form, fit, and function of a production part.

The basic questions to ask are these:

- Will the prototype be a static display model?

- Does it need to be fully functional?

- Are there multiple, interconnected parts?

- What is the surface texture and finish?

- What is it made from?

- How important is strength and durability?

- How closely should it match the final production version?

There are many variables to consider and we cannot cover them all here.

Our Rapid Prototyping For Various Industrial Applications

Many industries, like the medical and food service fields, rely on the rapid prototyping capabilities of Anpllo to meet their growing demand for parts used on critical production equipment.

Frequently Asked Questions

There are a couple of scenarios where rapid prototypes become a need. The first is when the cost of product development becomes too high. Rapid prototyping cost is lower than conventional prototyping, reducing product development costs. Rapid prototypes are also needed when you need to identify and evaluate product hazards as well as test functionality.

At Anpllo, the fast lead time for rapid prototyping is 5 working days. This is especially true when you use reputable brands that offer rapid prototyping online services for your needs.

Rapid Prototyping Resources For Engineers

How to Cost CNC Plastic Prototypes and Tips to Save Money

The cost of a CNC plastic prototype can vary based...

Read MoreMore about titanium metal

More about titanium metal Titanium is a metallic mineral known...

Read MoreWhat processes and services are included in CNC rapid prototyping

What processes and services are included in CNC rapid prototyping...

Read MoreContact US

Start Your Next rapid prototyping Project With A FREE Consultation!