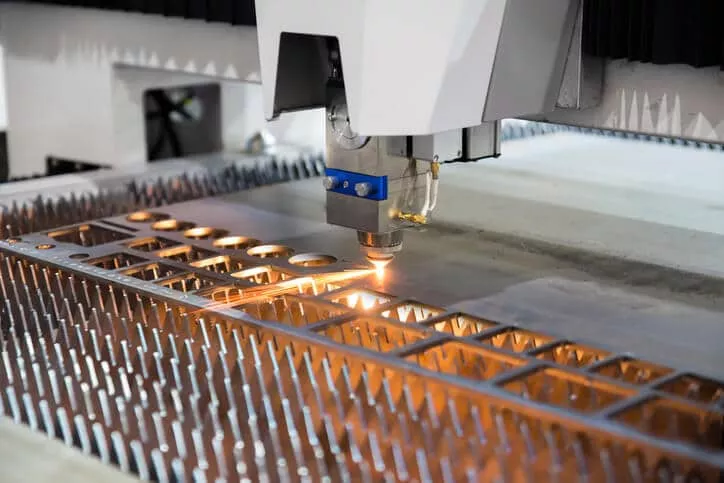

Plasma Cutting Services

Anpllocnc offers CNC plasma cutting services for companies looking to cut high-definition plate parts. Our high-definition plasma cutting machines are top-of-the-line and can produce anything from basic shapes to complex parts. Plasma cutting services are typically twice as fast as other cutting services and require fewer steps. This technique does not require the materials to be preheated, saving time and energy.

We Have the Capability to Design and Fabricate High-Quality Metal Products

If your project requires high-definition CNC plasma cutting of sheet metal or heavy plate metal Anpllocnc can help.

Our CNC plasma cutter can cut stainless steel, carbon steel, mild steel and aluminum as thin as 20 gauge and up to three inches thick with outstanding accuracy and efficiency. With one of the largest plasma cutting water tables in the area we can take on most projects, large or small. In addition to cutting standard shapes our plasma cutting system has the ability to bevel pieces at the plasma saving time and preparing the piece for welding.

We strive to provide quick turn arounds and get you the pieces you need as efficiently as possible. Our on-hand inventory of stainless steel, carbon steel and aluminums mean there is no delay in waiting for materials to arrive from an outside source before we can begin plasma cutting. Our clients that provide CAD drawings mean we can further expedite the fabrication process.

Beyond plasma cutting Anpllocnc offers a full compliment of metal fabricating processes, so if your project requires further manufacturing we can typically handle the job in-house.

To request a quote or learn more about our CNC plasma cutting services please to speak with a project manager or email [email protected]

Features & Benefits of High Definition Plasma Cutting

- Superior cut quality and consistency

- Efficient and cost-effective part production

- Fast turnarounds

- Virtually dross-free cutting through 1.5” (38mm) metal plates saves labor costs on grinding

- Superior squareness in comparison to oxy-fueled cutting processes

- Improved bolt hole quality

- 3.2” (80mm) maximum cutting capacity (edge start)

- 10’ x 20’ cutting envelope

- Compatible with any CAD/CAM/digital design files

- High precision and perfect repeatability

High Definition Plasma Cutting Capabilities

Our HD CNC Plasma Cutter can accommodate any high tolerance cutting application to meet the most stringent requirements. Our facility also houses Perforating Presses, CNC Turret Punches, Brakes, Bolt Hole Punches, Parts Leveler, Roll Formers, MIG, TIG, STICK Welding Equipment and Shears.

- Precision

- High Definition

- Rotating Bevel Heads

CNC Controlled

5 Axis

- Down Draft Cutting Table

- Automated Slag System

- Dross-Free Cutting

- Repeatable Cut-Edge Quality

- Hole and Internal Shape Cuts

- Duel Rotating Bevel Heads (Contour Bevels)

- Steel

- Stainless Steel

- Low Alloy Steel

- Alloy Steel

- Up to 2″ (Steel)

- Up to 1.5″ (Stainless Steel)

- Powder Coating

- Anodizing

- Painting

- Parts Cleaning & Degreasing

- Up to 40′

- Up to 10′

- Narrow to Reduce Waste

- ± .015″ (Gauge to .5″)

- ± .030″ (.5 to 1″)

- ± .060″ (1 to 2″)

Better tolerances may be achieved

- 5 to 10 ton

- Clean

- Package

- Bar Coding

*Free Delivery (150 mile Radius of Milwaukee or Rockford)

- Low to High Volume

- Inquire for current lead times

Tell Us About Your Customization Requirements

Perhaps you need an “outside the box” metal product to solve a unique manufacturing problem for your company. Or, you might have your own design you need help bringing to life. Our in-house design services include working with our customers’ concepts — just provide us with your product idea, and we can nest the design onto sheet metal using our high-definition CNC plasma cutting machinery. The efficiency and tight tolerances of our equipment ensure the most-cost-effective design and production process.

Why Use Plasma Cutting For Your Parts?

Plasma cutters are a good all-around sheet metal fabrication tool, though they lack the material cutting diversity of waterjet cutters and don’t have the precision of laser cutters. For larger sheet metal parts, plasma cutting machines are more cost-efficient than CNC laser cutters and can cut thicker materials easily. Plus, they are easy to operate and can cut at high speeds while maintaining precision.

Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures of all styles, including rackmounts, “U” and “L” shapes, as well as consoles and consolets.

Plasma Cut Parts

Plasma Cutting Resources For Engineers

No posts found!

Contact Anpllocnc

Consider Anpllocnc for Your Future Plasma Cutting Projects

Anpllocnc specializes in the most cutting-edge metal cutting technology, so you always receive the flawless product you expect. From metal bending to laser and plasma cutting, we have decades of experience transforming metal into a finished product that meets precise specifications. Contact our team or visit our plasma cutting shop near you to see how we can help your project reach new levels of quality.