Mold Making Services

Anpllo CNC is a full-service mold tool manufacturer, whether you need a prototype mold for low-volume production, or a mass production mold for millions of injections, we can handle it for you.

On-Demand Mold Manufacturing

Before your project is ready to begin, you need to make an important but difficult decision, which is to choose a professional mold manufacturer with reliable capabilities to work with. Because all high-quality products are manufactured by high-quality molds.

Anpllo CNC’s custom mold manufacturing services, from the design of the mold to the final testing of the mold, all processes are conducted in our in-house mold testing shop and mold shop. The mold testing workshop is adjacent to the mold workshop. Once the mold is manufactured, various equipment can be installed and tested within a few hours. This is the key to quick response. In addition, we reserve a large number of material warehouses for manufacturing high-quality molds, and we have a large reserve of spare parts that we can call for use at any time.

As a custom mold maker, we achieve success by taking a teamwork-focused approach with our clients, starting our partnership with a conceptual idea and continuing through custom design, mold fabrication, and production. This collaborative approach, coupled with our unwavering focus on ultimate customer satisfaction, has earned Anpllo CNC a stellar reputation for being 100% on-time, 100% quality guaranteed, and offering the most competitive prices.

Custom Mold Classification

Rapid Tooling

Short delivery time, suitable for low-volume production

Production Tooling

Medium delivery time, suitable for mass production

Precision Mold

High precision, tight tolerance, complex structure

Types of Molds We Are Offering

Plastic Injection Mold

Plastic injection molds are aluminum or steel molds used to make parts from a wide range of plastics, including nylons, acrylics, elastomers and reinforced materials like glass-filled polyamide. Custom plastic molds can last between 100,000 and 1,000,000 shots.

Metal Injection Mold

Metal injection molding (MIM) is a form of injection molding where a metal and binder mix is used as feedstock. A metal injection mold is usually made from tool steel to withstand the metal injection, but we can also use aluminum.

Die Casting Mold

Unlike many prototyping specialists, we can provide metal casting molds (and a low-volume casting service through our partners). These molds — typically made from hardened steel — can be used to make parts from aluminum, zinc, magnesium and other non-ferrous metals.

Investment Casting Mold

We can make low-cost investment casting molds by 3D printing a wax pattern and surrounding it with ceramic. The ceramic molds can then be used to make metal cast parts from metals like aluminum, zinc, magnesium, stainless steel and more.

Extrusion Mold

Our metal die molds can be used for aluminum extrusions of alloys like 6061 and 6063. We also make molds for plastic extrusions of materials like polystyrene, nylon, polypropylene and polythene.

Sheet Metal Mold

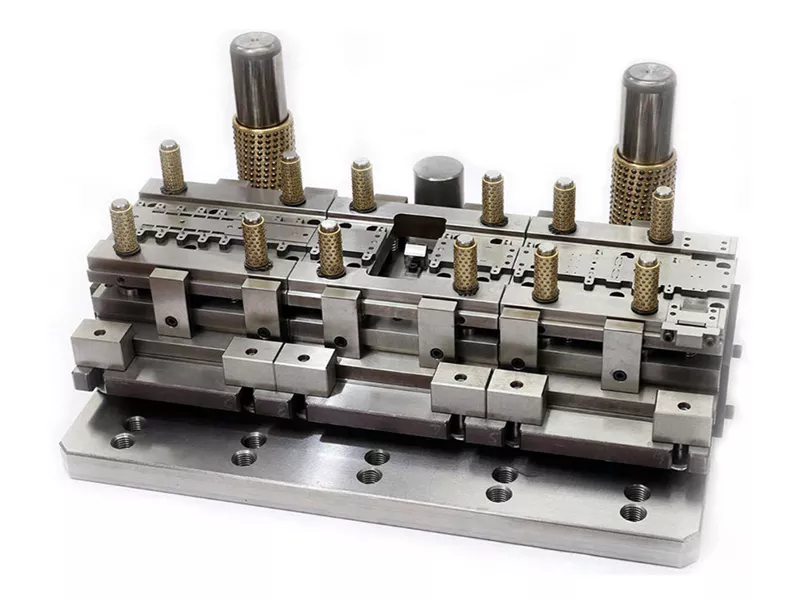

Our experience making sheet metal molds for stamping and bending allows us to create sheet metal prototypes.

Custom Mold Manufacturing Process At Anpllo CNC

1. Drawings Receiving

2. DFM Review

3. DFM Permitted

4. Materials Preparation

5.EDM Machining

6. Wirecut Machining

7. CNC Machining

8. Mold Fitting

9. Core Fitting

10. Mold Polishing

11. Mold Fabrication

12. Mold Trial

AnplloCNC Custom Mold Solution Service list

- Part Design

- Part Design Optimization

- Products Construct Design

- Product Design Assistance

- Mechanical Properties

- Cost Analysis

- Design For Manufacturing

- Reverse Engineering

- Products Updated Design

- Products Development

- Products Engineering

- process Engineering

- Tooling Plans

- Quality Requirement Planning

- CAD/CAM Design

- Mold·flow Analysis

- DFM Report

- Early Stage Engineering

- Complex Mold Design

- Highly Engineered Work Cells

- Material Selection Consultation

- Material Testing and Validation

- Product Testing

- Tooling Design

- Consulting Service

- Program Support

- Simulation Design & Analysis

- Precision Mold Tooling

- Double Injection Mold

- Overmolding Moulds

- Tow shots molds

- Hot & Cold Runner System Mold

- Insert Tooling & Molds

- Unscrewing Moulds

- Gas Assisted Molds

- large Size Molds

- Multi & Single Cavity Molds

- Full Service custom Injection Molding

- Precision Injection Molding

- Mass Production

- Die Casting Products

- small unit serial production

- Precision CNC Machining

- Custom Wire cutting & EDM Sparking

- Quick Change Molds

- Mold Repairing

- Metal or Plastic Component manufacturing

- Rapid prototypes

- Decorating Service

- Assembly & Packaging

Why Test Molds?

Testing mockups may result in a higher project cost, but it will bring huge improvements to your project. Test molds are mainly used in stages where product functionality and material durability need to be tested. Molds and molds during manufacturing can be a significant expense, but the cost is even greater if molds have to be re-molded due to design flaws and other issues. Trial molding is the process that helps detect these defects and improve the product. Test molds are typically used only a few times and cost less than 20% of the actual production molds. It’s a worthwhile investment.

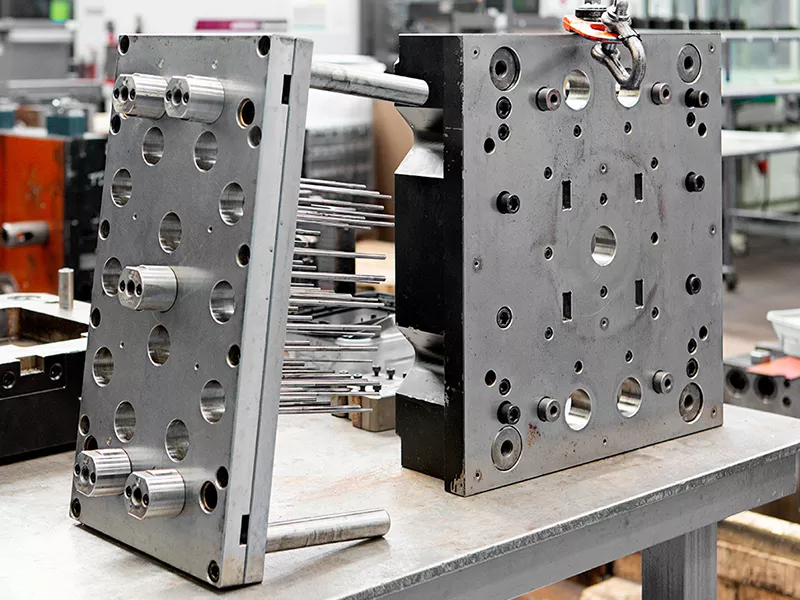

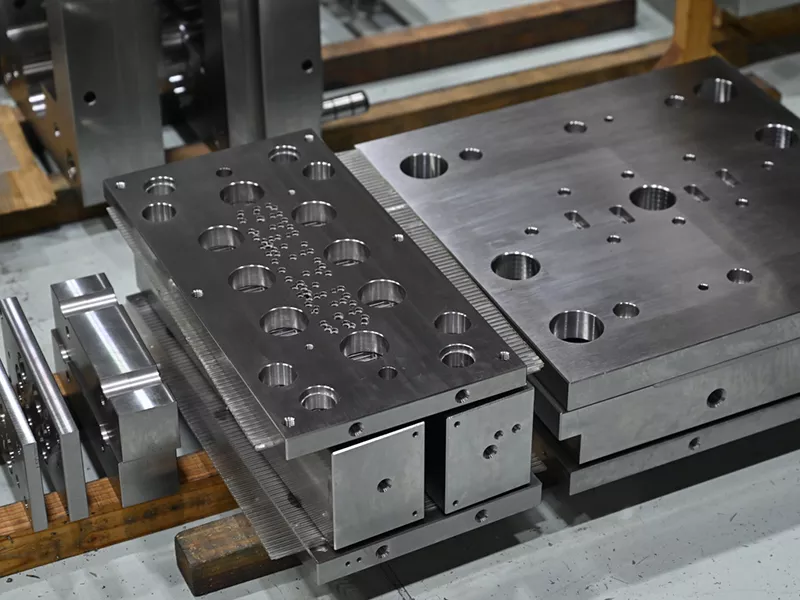

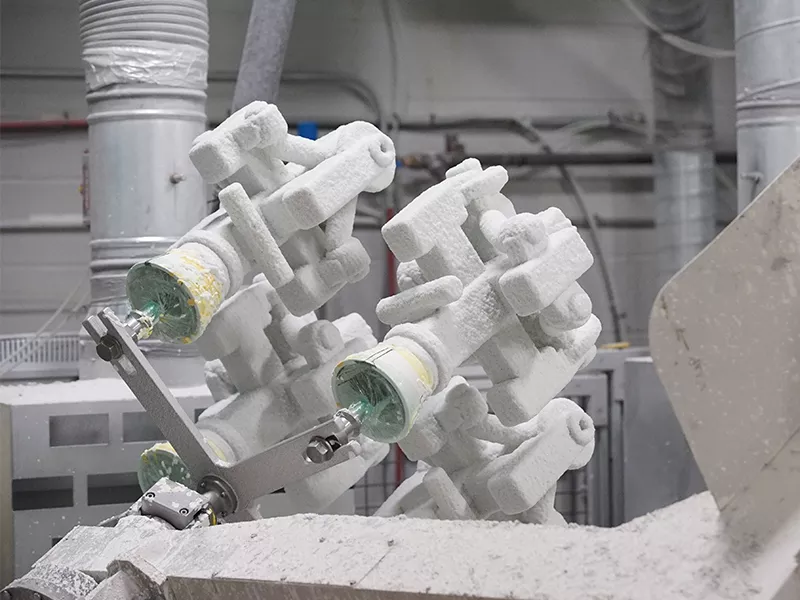

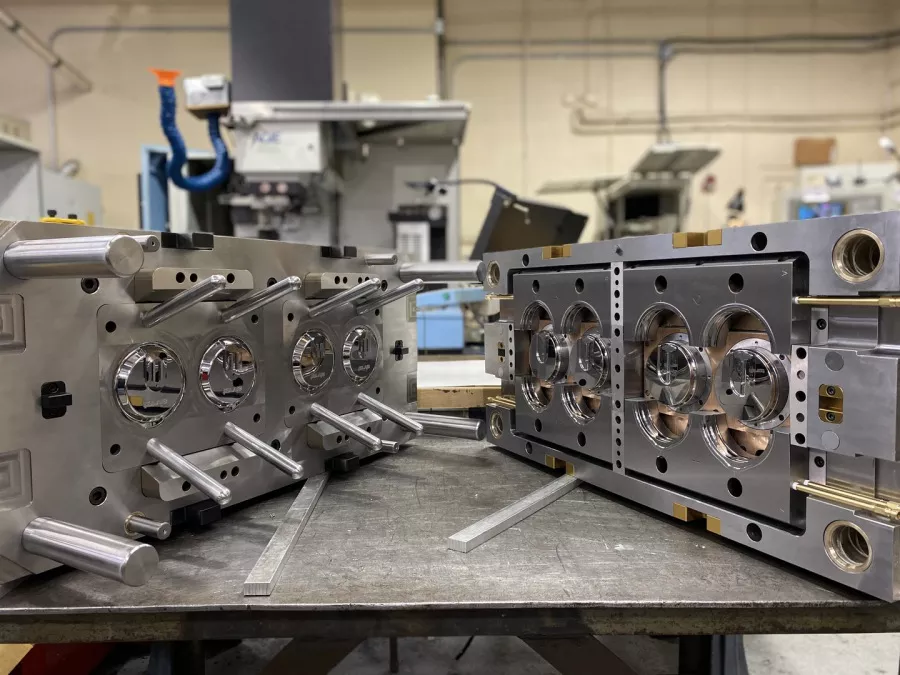

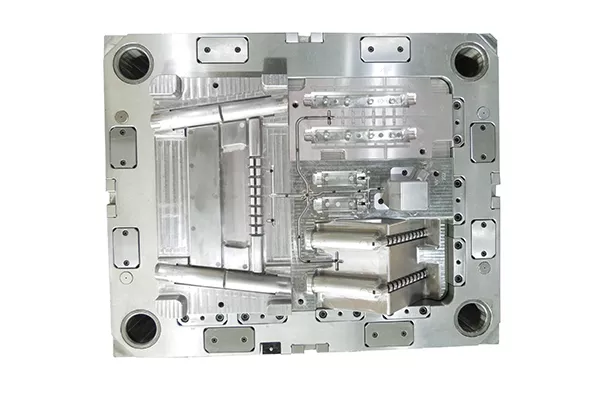

Our Mold Making Projects

How To Choose The Right Custom Mold Manufacturing Company Or Supplier?

Choosing the right mold manufacturing manufacturer or supplier is a critical decision that can have a significant impact on the success of your project. When evaluating potential partners, there are several key factors that can inform your choice.

- Experience: Look for mold making manufacturers with extensive experience in your industry or application. They should have a proven track record of delivering high-quality products that meet your specific requirements.

- Capabilities: Consider the company’s manufacturing capabilities, including equipment, technology, and facilities. They should be able to handle the size, complexity, and volume of your project.

- Quality: For mold manufacturing, quality is crucial. Look for a mold manufacturing company with a robust quality management system and a commitment to continuous improvement.

- Communication: Effective communication is crucial throughout the entire mold manufacturing process. Look for a company that is responsive, transparent, and easy to work with.

- Pricing: Mold making can be a significant investment, so be sure to consider your company’s pricing and payment terms. Look for suppliers who offer competitive prices and have a clear understanding of costs.

Get An Instant Free Quote

Ready to start your next project? We will provide custom mold manufacturing services according to your needs. Your needs can be told to us without reservation, although we will face strict quality standards.