More about titanium metal Titanium is a metallic mineral known...

Read MoreLow Volume Manufacturing Service

Low volume manufacturing is the best pathway to move from prototype to production smoothly, and provides on-demand low volume production with the ability to quickly deliver custom parts.

- Save costs; reduce risks;

- Shorten the time to market

- Enhance design flexibility

- Produce parts as needed

Anpllonc Low-Volume Production Service

Anpllocnc providing high-quality custom parts that meet your design requirements and specifications via vast low-volume manufacturing services, including CNC machining, rapid injection molding, vacuum casting, metal casting, sheet metal, press forging, aluminum extrusion, and more. We continue to enhance production management, process improvement, supply chain collaboration, and cost control to continuously improve customer satisfaction with fast, efficient, and competitive pricing.

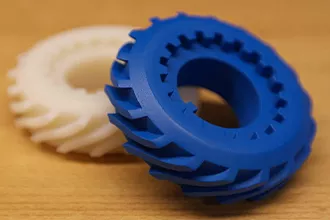

Low-volume manufacturing is a rapid production method that precedes full-scale production, ranging from 100 to 100,000 units. It does not require investment in expensive production tools, but reduces risk, allows design flexibility, shortens time-to-market, and creates opportunities for production cost savings.

On Demand, On Time Manufacturing For You

Our Low-Volume production quantity can be completed from dozens to thousands of pieces. Low-Volume production is different from traditional mold-opening production. We will achieve the goal of completing production through other processes and technologies. We recommend using rapid prototyping services if you only need a few products or prototypes. Our team has strict operating standards from the initial project evaluation and cost control, and production process control to the completion of production. We will maintain close cooperation with you at every step of the project. You can learn more about our work and technology, and we can provide suggestions for your project for free.

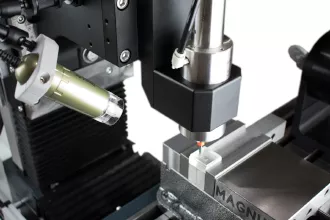

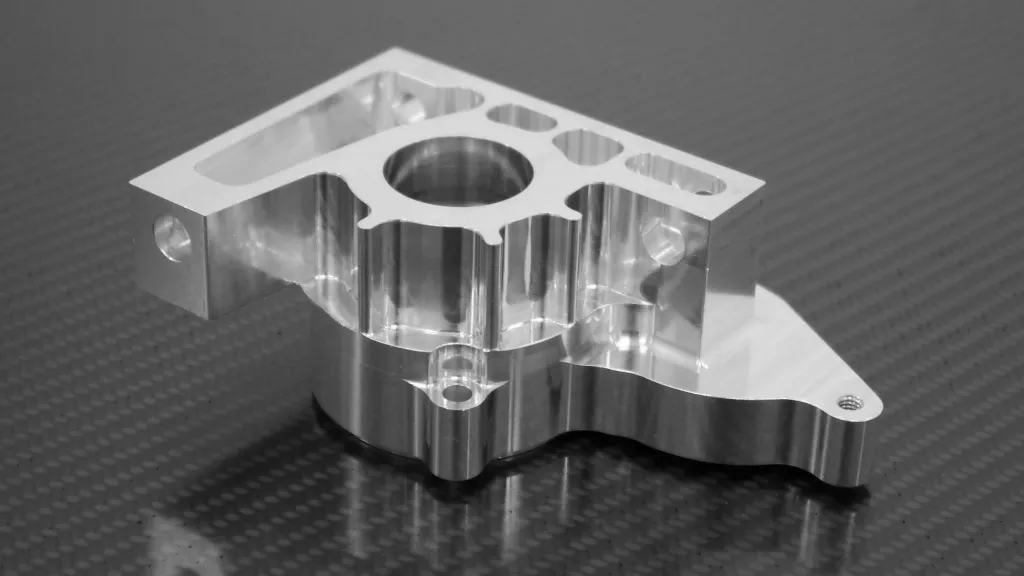

CNC Machining

CNC Milling

CNC Turning

Rapid Prototyping

3D Printing

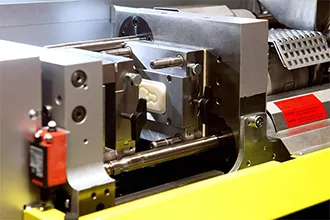

Injection Molding

5 Axis CNC Machining

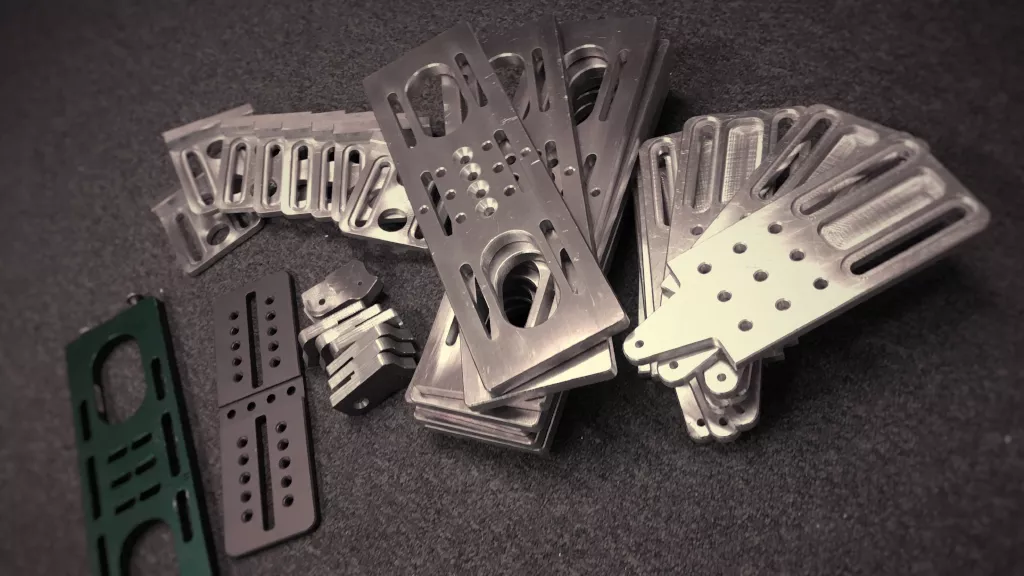

Sheet Metal Fabrication

Contact Anpllocnc

Request Your Free Low Volume Manufacturing Quote Today

So, what are you waiting for? Send us your inquiries and let’s get the ball rolling. Our team is ready to provide you with a personalized quote that will knock your socks off.

Why Choose Anpllocnc For Low Volume Production

- One-to-one support service by a technical team, quick response within a few hours.

- Most competitive prices in the market, 30% lower than Europe and America.

- Comprehensive capabilities include in-house machining and integration of manufacturing resources across China.

- An experienced team of engineers and flexible production methods mean faster manufacturing and shorter lead times.

What Is Low-Volume Manufacturing?

Low-volume manufacturing is a specialized service that offers full production-quality parts in volumes ranging from a single piece to a few thousand pieces. It’s ideal for moving an idea from the concept stage through prototyping and from there as a bridge to full-volume production.

Low-volume production is considered a specialized service because most manufacturers don’t want to do it. Their assembly lines and supply chains are optimized for large production volumes that leverage economies of scale. There is nothing wrong with that approach because it’s the best way to ensure the lowest cost per piece. However, it usually requires large minimum order volumes and a commitment to expensive tooling.

But what is a product developer to do if you want to start with product volumes on the low end, from one part to one thousand? That’s where Anpllo can help.

Advantages of Low-Volume Manufacturing

Are you wondering how low-volume manufacturing can help your product go from concept to completion? There are a number of advantages to using this service that you may not know about. Here are the most prominent benefits

- By producing a small-run of parts or products, you will gain rapid access to emerging markets before the competition.

- Compared to full-scale production, low-volume manufacturing will reduce the cost of tooling without requiring any minimum orders.

- Low-volume manufacturing enables you to shorten overall production lead times, saving you time and energy when it comes to product development.

- If there’s an encounter with shorter product life styles, low-volume manufacturing allows you to respond quickly and iterate parts in a more optimal way.

- Lower exposure to unnecessary financial expenditure, keeping you from breaking the bank on high-volume production.

- Lastly, the quick turnaround that comes with low-volume manufacturing also allows for faster design changes, reducing costs and overall production time.

Helping You Choose The Best Options

Our team of low-volume casting and machining experts is happy to help select the best low-volume manufacturing options for your parts. We work with your product developers to bring your designs from conception to completion. We also provide many services such as:

- “Replacement” parts for parts that are no longer in production or are otherwise unavailable. These are often parts for repair or refurbishment.

- They provide a “bridge” between the prototype phase and the high-volume production phase where parts will be manufactured using the production (hard) tooling. Some people refer to these as pre-production parts.

- Low-volume production parts are parts made after the prototype phase. These parts ARE the production parts and hard tools are not paid for or required.

Need a low-volume production sample? We can offer metal casting samples for your casted parts. You will be able to see our true expertise and skills before committing to production.

For help in deciding what process you should pursue or questions about low-volume casting, please contact our low-volume manufacturing experts.

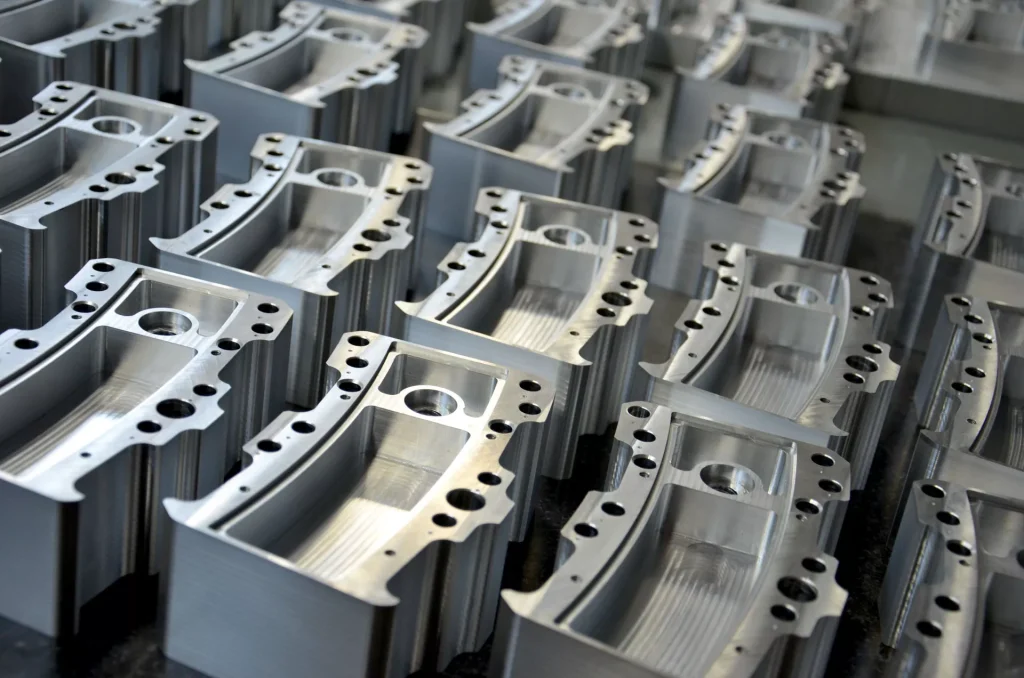

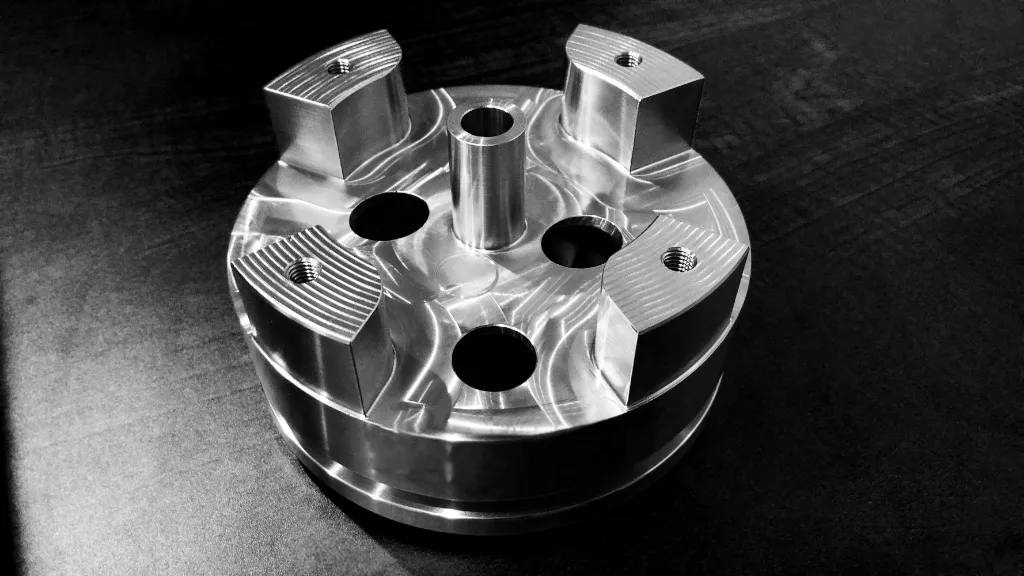

Low-Volume Parts Produced By Anpllocnc

Work With Nearly All Industries

Anpllocnc’s on demand production parts play a crucial role in various industries, making us the premier manufacturer of choice.

Anpllo Low-Volume Production Service FAQS

There are several factors that separate our low-volume production service from the competition. For one, we offer an extensive variety of complementary in-house services — including CNC machining, vacuum casting, plastic injection molding, and finishing — to deliver our clients comprehensive prototyping and NPI (new product introduction) solutions.

Secondly, we offer best-in-class material verification and testing services. Plus, we don’t require a minimum order volume or minimum dollar value, and we use state-of-the-art AI quotation algorithms for fast, accurate quotes.

Yes, our team completes all manufacturing at our facilities. This gives us a quality control advantage over other low-volume production services that outsource their manufacturing.

We routinely work with all conventional metals including copper, brass, stainless and mild steel, magnesium, and aluminum. We also have a robust supply chain with thousands of commercial plastic resins, including transparent plastics, engineering- and medical-grade plastics, glass-filled plastics, and more.

The quality of your low-volume production parts is guaranteed by our rigorous control standards. This starts with an inspection of incoming materials to verify the integrity of all materials used. It also includes in-process inspection and testing to make sure you get parts that exceed your expectations. Certificates of Compliance are available upon request for all materials. For clients who can’t visit our facilities in person, we also offer detailed video files showing all production steps.

Low-Volume Manufacturing Resources For Engineers

Low-volume CNC machining shops: how to identify their strengths

Low-volume CNC machining shops: how to identify their strengths Multi-variety,...

Read MoreContact Anpllocnc

Ncrease your "value", Everything is for the future!

Are you in need of some customized small quantity products? Like to work with a professional partner? Get in touch with us today!