Rapid Tooling (RT) Service

Anpllocnc provides aluminum mold and steel mold for rapid tooling according to the needs of customers. It can hand over the parts of your designated materials within 2-5 weeks. From functional prototyping to low volume production to mass production of parts, we combine rapid injection molding advanced equipment with proprietary technology and experienced manufacturing teams to provide high quality injection molding parts, so as to help you reduce design risk and save overall production cost.

- ISO 9001:2015, ISO 13485 Certified.

- Cost-effective and Fast Turnaround

- Free DFM for Excellent Results

- Fast delivery in Days

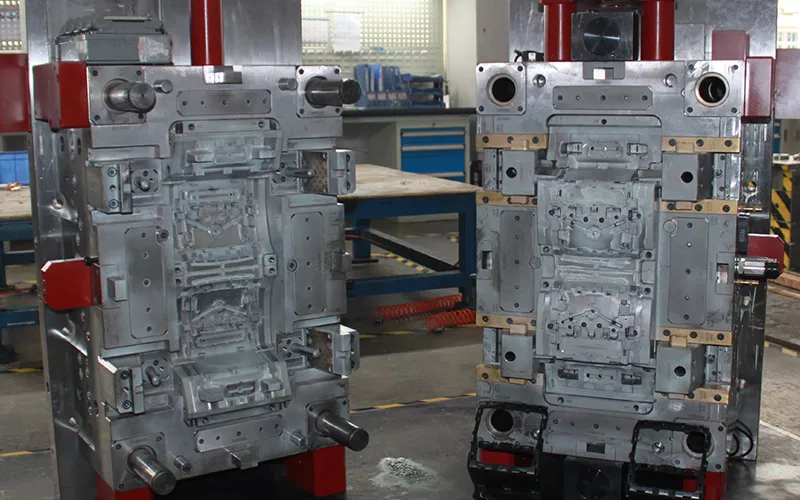

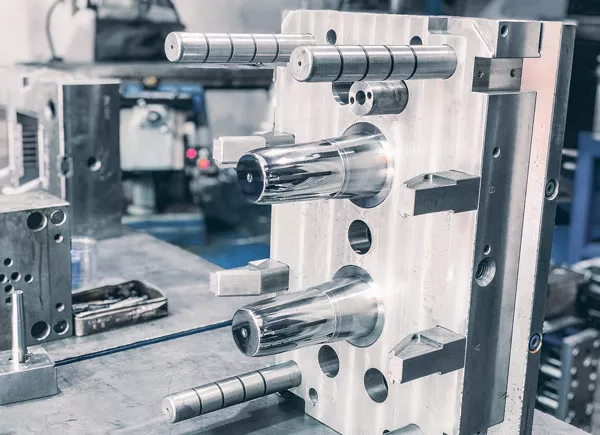

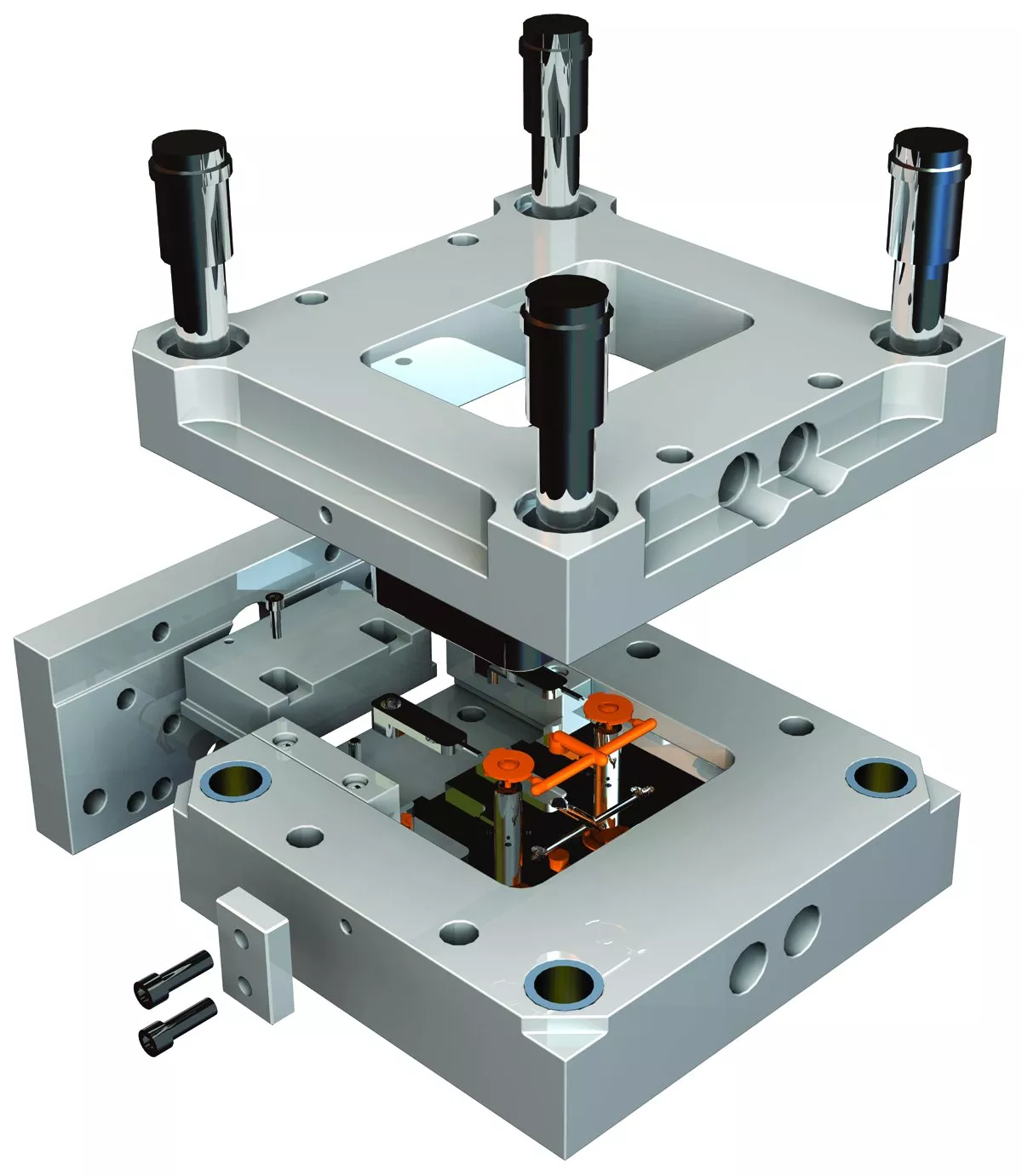

Rapid Tooling Development

Our solutions drive productivity in all areas of manufacturing – from accelerated prototyping through to full production-scale manufacturing

Rapid Tooling is one of the most-effective means of bridge tooling and low-volume mold production. Anpllocnc delivers one of the best rapid tooling technologies to cater for low to medium volume manufacturing needs at low cost prices. Our rapid tooling process is optimized to produce you with quality injection-molded parts of both simple and complex geometries in real materials in the quickest possible timeframes.

At Anpllocnc, we are able to run hand-loading inserts for ultra-low volume demands. We also offer comprehensive support for rapid tooling and provide value-adding solutions that range from product design assistance (DFM) to material selection, product structure optimization, mold design detail, flow analysis and other post-molding services (polishing, texturing and sandblasting) that will help to put you in pole position to introduce your concept to the market in only a number of weeks.

Anpllocnc’s Rapid tooling uses a number of interchangeable mold base tooling to simplify complex tooling structure. We work with an interesting range of tooling in Aluminum, P20, NAK80, S136H and other materials. Our tooling life ranges from 5000 to 500000 shot depending on the geometry and simplicity of the part and the material used. Our in-house capability and experience also means that we are able to deliver excellent quality end-use parts at faster and cost-effective rates.

Rapid tooling can deliver about 40-50 percent cost and time savings over traditional molding techniques. Our tooling lead time is as quick as 5-20 days based on the final product to be produced and tool structure.

Our Rapid Tooling Capabilities

Time-Saving

Shared mold bases and flexible tooling components reduce prototyping time. In a traditional environment, manufacturers need to produce molds, tools, and patterns, but Rapid Tooling can save you that time and get samples quickly.

Support Modification And Customization

Home mold and tool modifications are available. Help designers complete the construction of ideas, facilitate the testing of new products, and rapid mass manufacturing

Short Delivery Time

Tooling lead time is 1-2 weeks, depending on part geometry. We have the fastest mold processing process, you only need to provide your parts CAD file, we will make and product in the shortest time. At the same time, because we have been cooperating with the logistics companies with the best reputation, we can ensure that you can receive your model or parts in the shortest time.

Supports Multiple Materials

Manufacturers can apply this process to a variety of metallic and non-metallic materials such as aluminum, silicone rubber, epoxy, and more. During the creation of the mold, reduce the constraints imposed by the material on the designer.

Reliable Product

Rapid prototyping tools have lifetimes ranging from 500 – 5000+ cycles. Our tools are tested before being shipped to customers to ensure excellent performance.

Test Production Parameters

Our engineers will oversee the manufacturing process of the tool. The error data of the model is fed back to the customer in time and provides modification suggestions to help the customer complete the sample production.

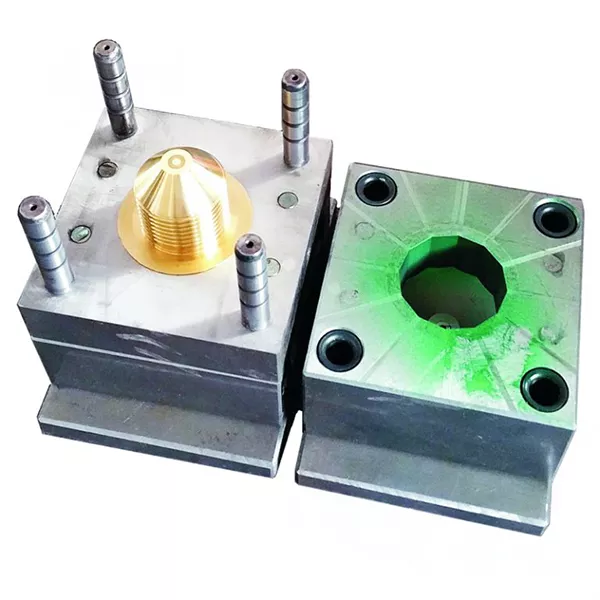

What Rapid Tooling Services Can We Provide?

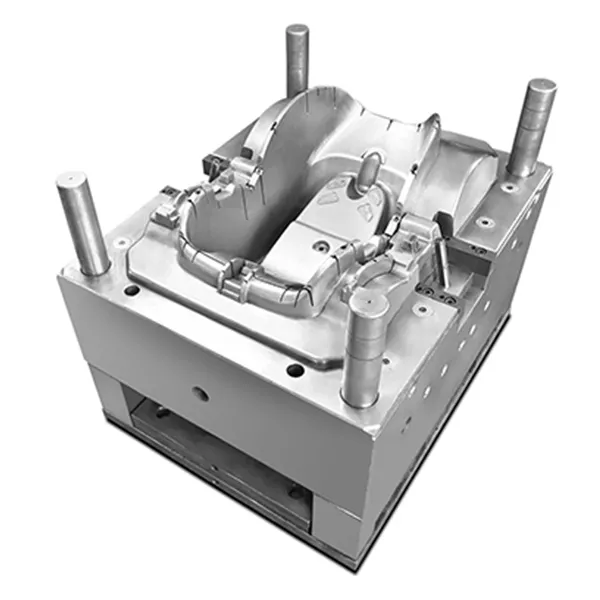

Plastic Injection Mold

Plastic injection molding uses in the mass fabrication of plastic parts. It involves melting plastic pellets (thermosetting/thermoplastic polymers) that, once flexible enough, are injected at pressure into a mold cavity, filling it and solidifying it to create the finished product.

It is ideal for manufacturing high volumes of plastic products, which serves quite a lot of industries and individuals. Injection molding is referred as a highly productive and efficient method in fabricating plastic ones. It can produce identical parts consistently.

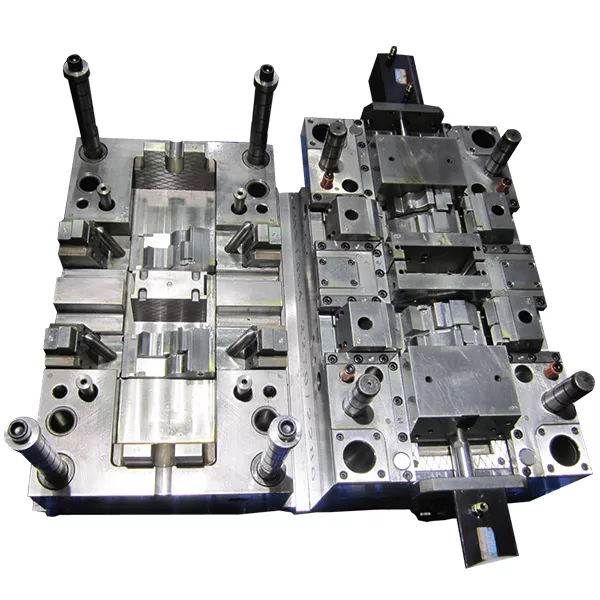

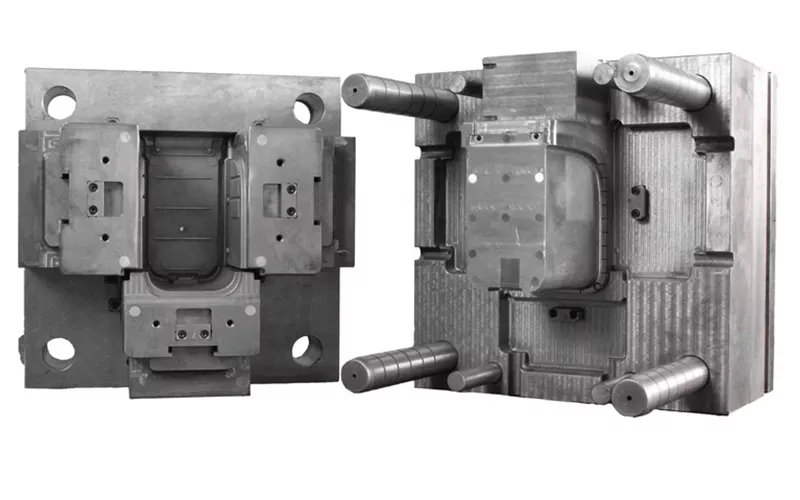

Die Casting Mold

Die casting is a metal casting process in which molten metal is forced into a steel mold under high pressure into a mold cavity. The whole process consists of five steps: clamping, injection, cooling, ejection and trimming.

Although die-casted parts involve higher initial costs compared to other casting methods, it affects to result in lower per-unit costs for high volume production. Using die casting helps to think of it as a method of conversion or a way of turning one thing to another.

Compression Mold

Compression molding is a composite manufacturing process normally used to produce composite components in high volume production like automotive parts. It is a mold type in which a charge of material is squeezed into shape by compressive force.

It is widely used, simple and flexible method of fabrication. During the production time, it shows greater reproducibility and lesser cycle time. This technique uses hot matched metal die with a vertical hot and cold press arrangement for compressing the materials.

About Anpllocnc

Anpllocnc invested in an independent injection molding plant in 2020 to provide rapid injection molding and traditional injection molding services using a variety of materials and technologies, as well as bridge tools for prototype testing and pre mass production evaluation. We will deliver injection molded parts according to your plan and help solve any problems that may arise in the whole production process.

At Anpllocnc, we have a team that specializes in rapid tooling for aluminum and steel. With technical experience in injection molding, rapid prototyping, CNC machining, EDM / WEDM machining and special finishing, ensure that the parts produced meet and exceed your highest expectations.

Quote online

High Quality and cost effective rapid tooling service

Anpllocnc is a leading rapid tooling service provider in China that offers high-quality and cost-effective quick tooling services to customers from various industries.

Whether you need a prototype, a low-volume production or a mass production, we can help you achieve your goals with our rapid tooling services.

We use advanced technologies and equipment to create rapid molds and parts with fast turnaround time and high accuracy. We can also provide various surface finishing and assembly options for your parts.

We have a team of experienced engineers and designers who can deliver complete rapid prototyping and tooling solutions for your product development needs.

What is Rapid Tooling?

Rapid Tooling is a concept that is changing the manufacturing industry. For understanding, we have to keep in mind that injection molding is the status quo of producing plastic parts in high volume. For that, the mould tool for production can be expensive and risky during the development stage of your product. This issue can be solved by using SLS (selective laser sintering), a type of 3D printing. This process opens the possibility of producing the moulding tool much faster and cheaper. Contacting our engineers can save you and your company a lot of money because they create the mould tool faster than conventional production methods.

How to Process Rapid Prototype Tooling?

As you can see from our engineering overview, SLS is a way of 3D printing where a laser melts the metal powder, and the molten metal creates a 3-dimensional part. In Rapid Tooling, this part is used as the prototype for recreating this as plastic parts. Rapid Tooling can reduce the time required to produce a mould tool by cutting the prep work to the least. Consequently, this process can save you and your company precious time and money.

Main differences Between Rapid Tooling And Standard Injection Tooling

Rapid Tooling

- Tool materials used: Hardened Steel or Hard Aluminium offer higher durability*

- Tool life: Tens of thousands of parts per cavity

- Manufacturing time: Tools manufacturing usually takes 2 to 3 times longer than prototype tooling

- Price: Tooling cost is always higher than prototype tooling

Standard Tooling

- Tool materials used: Hardened Steel or Hard Aluminium offer higher durability*

- Tool life: Tens of thousands of parts per cavity

- Manufacturing time: Tools manufacturing usually takes 2 to 3 times longer than prototype tooling

- Price: Tooling cost is always higher than prototype tooling

*A limited tool life is shorter because the tool materials chosen are softer and the tool concept and configuration is simpler than those used in Standard tooling; this does not mean that parts quality is compromised; moulded parts will always match the standards achieved from standard tooling.

Rapid Tooling Gallery

Advantages Of Rapid Tooling

· Short lead time. Molds or tools can be ready within days or weeks.

· Easily reproducible.

· Helps to reduce prototyping and product development cycles.

· Helps to test the parameters for mass production, such as the materials and product design.

· Very suitable for short-run production of up to 5,000 parts.

· Highly customized for personal application.

· More cost-effective than conventional tooling methods.

More And More Customers Use Rapid Tooling As The Process Of Choice For Small Batch Manufacturing

Resources Related To Rapid Tooling

No posts found!

Contact Anpllocnc

Let us be your supplier for Rapid Tooling

We have the ability to produce short series of plastic and metal parts and components of new products for any sector or activity at very competitive prices and compressed delivery times.

Our project management team will provide you with the best technical support during the entire developing process of your project.

And of course, we guarantee complete confidentiality of your project.