Overmolding Service

Anpllocnc provides a superior overmolding service that is a cost effective and efficient solution to enhance the durability and functionality of your product. Secondary molding provides an additional layer of protection that improves grip, cushioning and appearance. With over 10 years of injection molding experience, we have successfully overmolded a wide variety of products in a variety of industries, including automotive, electronics and consumer products.

- No minimum order quantities

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certificated

- 24/7 engineering support

Your Reliable Overmolding Manufacturer

Anpllocnc is a reliable overmolding supplier from China. We offer a wide range of high-quality overmolding products that can help you design and produce the perfect product. With our experienced team, we can help you create a flawless product every time.

We understands that every injection molding project is unique and may require a different injection molding method. That’s why Anpllocnc has invested in top-level injection molding equipment and a professional team with comprehensive injection molding technology training. Our team is composed of designers, mold engineers and production engineers, all of whom cooperate with each other tacitly. This ensures that each plastic part and mold design is optimized for overmolding and that the resin material chosen is ideal

With over ten years of experience, we offer our customers unmatched knowledge and experience in the field of designing, manufacturing, and tooling of overmolding products at competitive prices across the globe while maintaining a commitment to quality.

Anpllocnc Overmolding Process Capabilities

Anpllocnc provides Overmolding process customization service from design to finished product. While providing excellent quality, we can complete the mold production in the fastest 15 days

200×200×150mm |

8×8×6 in |

4×4×4mm |

0.15×0.15×0.15mm |

0.5 mm |

0.02 in. |

0.025 mm |

0.0008 in. |

0.1mm |

0.004 in |

- ABS

- Polypropylene

- Polycarbonate

- Acrylic

- Nylon

- POM

- PTFE

- PBT/PBT-PC

- PEEK

- HDPE

- PVC

- PPS

- PI

- PAI

- UPE/UHMW

- PVDF

- ULTEM (PEI)

- PE

- PS

- PET

- EVA Foam

- EPS Foam

- PU Foam

- TPE

- TPU

- Silicon Rubber

- Glossy:A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts.

- Semi-glossy:B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture.

- Matte:C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture.

- Textured:D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish.

100mm from the parting line |

3.94in. from the parting line |

Provide T0, T1, T2 samples before mass production

First Article Inspection, ISO 9001, ISO 13485

From mold making to sample delivery: 15 business days

Trimming, Assembly, and packaging

The Advantages Of Overmolding Injection Molding

Anpllocnc’s overmolding service provides unmatched durability and design flexibility. Our advanced techniques apply a protective material layer over substrates for superior protection against wear, impact and weather. Overmolded products last 50% longer versus non-overmolded. Overmolding also reduces costs by eliminating assembly steps and material waste, with customers reporting 30% faster production and 15% higher productivity. As an experienced, reliable overmolding partner we enhance product quality and functionality.

Improved Design And Creation Of Custom Plastic Parts

Overmolding allows for the creation of custom plastic-plastic or metal-plastic product combinations with high dimensional accuracy.

Better Product Performance

Overmolded parts are of excellent quality because of their two-material advantage. For example, a hard plastic substrate can be overmolded with a soft rubber layer to improve grip and shock absorption.

Increased Shelf And Aesthetic Appeal

The overmolding process can be optimized with many materials and surface treatment processes to improve the aesthetic quality of the product. For example, an overmolded part can be given a different color or finish than the substrate material.

Better Shock Absorption And Overall Durability

Overmolding also offers improved shock absorption and durability due to the addition of a soft rubber layer. This can extend the shelf life of the product and improve its resistance to impacts.

Lower Production Costs

Overmolding can reduce production costs by eliminating the need for post-assembly. For example, an overmolded part can be made with a single mold, instead of requiring two separate molds for the substrate and the overmold.

Contact Anpllocnc

Get the Best Plastic Overmolding Services from Anpllocnc

Overmolding is an essential tool to achieve functional, great-looking, and high-quality plastic products. At Anpllocnc, you’ll receive not only the best plastic overmolding services but also an experienced team that will help you every step of the way.

From initial designs to packaging, our expert team will provide the ideal solution for your exact project requirements. And, thanks to our vast selection of equipment and materials, we have everything you need to create even the most complex and customized plastic projects. Contact us today to learn more!

Precision Mold Design For Overmolding

Overmolded structures are often larger than typical injection molding parts. Their designs are equally more structurally complex. More so due to the fact that they may involve the use of different materials that shrink at different rates. Precision is, therefore, very important when developing mold designs for overmolding processes.

Anpllocnc has worked on numerous overmolding projects and we have perfected our skills through these experiences. We take into consideration the part design and the materials that will be used for overmolding, right from the start. This enables us to design molds with precise dimensions, draft angles, and high tolerances. We further test each mold design to ascertain its accuracy. Subsequently, our clients are able to realize quality overmolded parts because all their manufacturing needs are anticipated and addressed accordingly.

Why Choose Anpllocnc For Your Custom Plastic Overmolding Project?

Anpllocnc is proud that we can offer you high-quality plastic overmolding parts and respond to you quickly.

Anpllocnc is a very energetic team. Over 90% of staff are under 35 years old. We are 24/7 available for your plastic overmolding projects. Once you send us 3D files, we will give you a fast quote within 2 hours. After the quotation, our engineers will give you the most professional advice. And our sales team will keep in touch with you. If you get confused about anything, we will explain it to you ASAP.

If you are not sure about our quality issues, you can send also us your 3D files firstly. Then, we will make a free sample according to your specifications. If possible, we would like to invite you to visit our factory about the plastic overmolding.

Want to know more about us? Just send us an E-mail here!

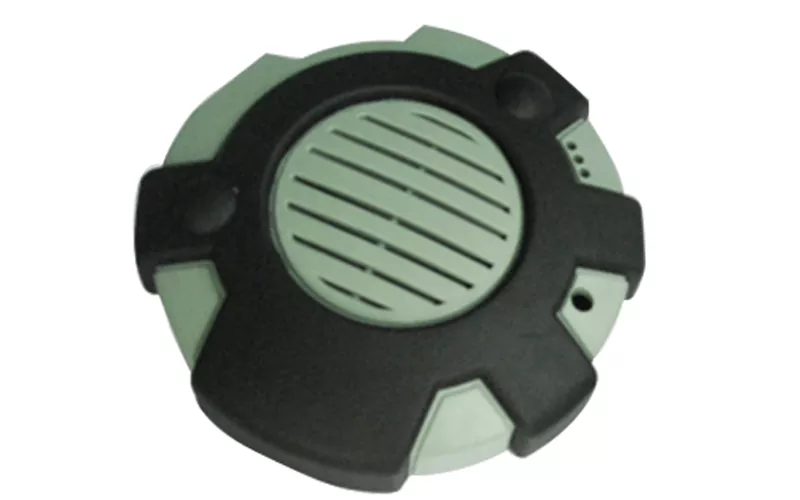

Custom Overmolding Parts Gallery

At our custom overmolding parts gallery, we understand that every project is unique. That’s why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

What’s The Difference Between Overmolding & Insert Molding?

Insert molding and overmolding may look similar on the surface, but these processes are a bit different.

Overmolding is used to build one part, and then place another layer of plastic, injection-molded material over it. For example, a plastic bicycle handlebar with a soft silicone grip would be an overmolded part.

Insert molding, in contrast, is the process of loading a preformed part (usually metal) into a mold, where it is molded with a special thermoplastic resin to create the final component. For example, brass contacts may be embedded in a plastic resin to create a plastic electrical connector, or a metal threaded insert may be placed into a plastic housing.

Applications of Overmolding Services

This technique is widely used in various industries to improve product performance, enhance the aesthetic appeal, and provide additional functionalities to the end product.

Explore Related Resources

No posts found!

Contact Anpllocnc

Get Started With Our Overmolding & Injection Molding Services

At Anpllocnc, we take pride in providing our customers with the injection molding services they need to create high-quality products. If you’d like to learn more about two shot molding or injection molding, please contact us right away.

We would be happy to discuss your project, go over the design, and discuss pricing and production details. Get in touch online now, and get started right away!