Liquid Silicone Rubber (LSR) Injection Molding

Custom Liquid Silicone Rubber (LSR) Parts on Spec and on Time,Whether you’re looking for a single Liquid Silicone Rubber (LSR) component design or a full device with LSR components, Anpllocnc Solutions can help. From part design assistance to tool design and build to liquid injection molding to assembly, count on our Liquid Silicone Rubber (LSR) molding experience and proven silicone injection molding process to ensure your parts are delivered to spec, to quality and on your rigorous timeline.

Professional Medical Liquid Silicone Rubber Injection Molding Manufacturer

Anpllocnc has been meeting the industry’s needs for medical silicone components since 2020. We have complete and expert knowledge in using a full range of silicones covering various properties and properties.

Multiple sets of highly automated horizontal injection molding machines are deployed at our manufacturing base in China. The factory has a certified Class 10,000/ISO Class 7 clean room.

Compared with other silicone molding manufacturers, Anpllocnc’s production team is more experienced and dynamic. We have always made custom Lsr injection molding production the top priority of our business, and we focus on bringing the most suitable solutions and reliable products to our customers.

Anpllocnc promises the precision of silicone rubber parts to meet customer expectations. After long-term development and improvement, our factory has established a strict and complete quality management system to test and evaluate product quality in each production link.

Silicone & Rubber Injection Molding Process For Medical Need In Anpllocnc

As one of the silicone injection molding companies, we produce custom silicone and rubber molding for the healthcare industry. LSR plastic injection molding offers great flexibility in design and tooling, which helps in producing complex geometries and consolidating multiple functional characteristics. It also assists in producing reliable medical products at lower costs.

Design & Prototype Service

Being one of the top silicone part manufacturers, we depend on in-house tooling and process engineering to provide unlimited design and prototype capabilities while improving the quality and ensuring consistent tolerance. These services are delivered by us at cost-friendly prices.

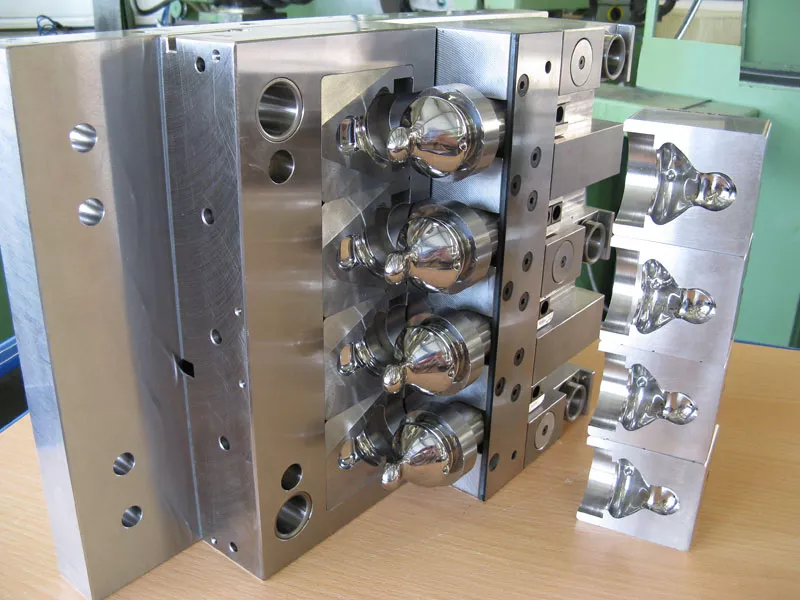

Mold tooling Design and make

Our holistic approach to LSR molds relies on working with customers to create innovative solutions, keeping their unique specifications and requirements in check. The plastic medical consumable supplies provided by us offer the highest consistency in the product dimension, precision, and overall quality.

Rigorous Material Selection

Our process chromatography items help in increasing your yield by eliminating impurities and enhancing the efficiency of the purification procedure. The chromatography resins and columns used help reduce the total purification steps while yielding bioprocessing applications.

CNC machining

For medical silicone molding, we use CNC machining technology. It uses automated and high-speed cutting tools to create innovative designs from metal and plastic. This computerized manufacturing technology is ideal for producing equipment for the healthcare industry.

Medical Molding Method in Clean Room

At Anpllocnc, a professional silicone molding manufacturer, we use a cleanroom molding for medical silicone parts manufacturing to reduce the risk of contamination by dust and other minor particles. That’s how we maintain zero-defect quality levels by utilizing in-process controls.

Secondary Operation

We take LSR injection moulding to the next level by offering the healthcare industry a multitude of secondary operations and assembly line options. We offer fully labeled and assembled silicone and rubber molded parts and sub-assemblies for better quality, efficiency, and cost saving.

Clean And Hygienic Production Process

Anpllocnc offers different LSR product production such as LSR overmolding, LSR multi-shot, two-shots, and more. All our production lines are fully automated with minimal human contact. Our factories in China are guaranteed to be clean and climate-controlled.

The production process for LSR parts is guaranteed clean and hygienic. We ensure that all silicone medical products comply with ISO hygienic requirements and strict cleanliness standards. Our factory has two-shot and single-shot ISO class 8 cleanroom production lines.

Manufacturing Technology For Intricate Components

No matter the quantity, you can count on Anpllocnc to provide custom-molded silicone components of unsurpassed quality on time and within budget. Anpllocnc’s best-in-class Liquid Injection Molding, HCR and Overmolding manufacturing technologies are backed by extensive product engineering experience, vast material knowledge, in-house automation and tooling expertise along with the project management skills critical to keeping production on track.

- HCR transfer molding using specialty silicones

- Liquid injection molding (LIM)

- Custom rubber molding

- Rubber Overmolding (two component or 2K) – rubber to metal and rubber to plastic bonding

- Liquid silicone

- Specialty silicones

- Thermoset rubber

- Bond to plastic and metals (HCR/LIM)

- Chemical bonding (HCR/LIM)

- Self-adhesive (LIM)

- Engineering

- Automation

- Product development

- Rapid prototyping

- Mold making

- Rapid Tooling

- Slitting

- Die cutting

- Assembly

- Special packaging

- 150 to 800 tons (HCR/OM)

- 5 to 140 tons (LIM)

- Down to .020 in (HCR/OM)

- Down to .015 in (LIM)

- Up to 20 in x 20 in

- Up to 16 in x 16 in (LIM)

- ± 0.002 in

- Single, Multi-cavity, and Family molds;

- Prototype

- Low volume production

- High volume production

- Flexible lead times

- Just in time production

- OGP (non-contact)

- Automatic vision measuring

- A2LA accredited lab

- Material development

- Product test lab

- Environmental

- Salt spray

- Force

- Leak

| FINISH | DESCRIPTION |

|---|---|

| PM-F0 | non-cosmetic, finish to Protolabs’ discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |

Quote online

Custom Silicone Rubber Injection Molding Service For Your Business

Anpllocnc has built a team of plastic injection molding experts with years of experience, ensuring your LSR components are manufactured with quality every step of the way. We offer plastic injection molding, two-shot molding, precision tooling, assembly, heat staking, and more. With our innovative technology, we utilize high-quality resources to ensure you reach your deadlines on time. Our expanding facility, located in China shenzhen, provides enhanced manufacturing capabilities with a team that will help you with your project needs from start to finish.

Our Liquid Silicone Rubber Injection Molding Capabilities For The Medical Industry

Since Liquid Silicone Rubber Injection Molding can produce intricate elastomeric components in short cycles, it is steadily gaining a foothold in the medical markets. At Anpllocnc, a rubber & silicone molding company, we depend on this material due to its biological inertness and long-term product stability.

Liquid Silicone & Rubber Overmolding

For reducing costs, improving the quality of our medical products, and extending their lifetime performance, we utilize liquid silicone and rubber medical overmolding techniques. Due to its biocompatibility, we use silicone overmolding to produce a broad array of medical devices.

Silicone Micro Molding

We use silicone micro moulding, the latest trend in LSR manufacturing to produce small, highly accurate, and high precision parts. As the medical components are getting smaller, we strive to deliver our customers incredible accuracy and precision in all our LSR products.

LSR Compression Molding

Our team of experts utilizes this highly complex molding technique for producing composite medical components assembly in high production volume. LSR compression molding procedure involves low tooling costs. This is best for manufacturing large items and thicker parts, and is cost-effective for short production runs.

Silicone Prototype

For the medical industry, we also manufacture silicone prototypes by employing a lot of patience and experience. We understand that moving ahead without a prototype is extremely difficult. That is why we offer silicone prototypes to verify that your design will perform as intended.

Silicone Insert Molding

At Anpllocnc, we use the silicone insert moulding products and techniques for the medical industry as it molds the silicone through a substrate material to produce the final part. By combining the best of two materials, this process supports variations in durometer and rigidity.

LSR Tooling

Creating a precise, high-quality liquid silicone rubber part must begin with a high-quality mold. At Anpllocnc, we have in-house CNC milling and CNC electrical-discharge machining tools that allow us to create your mold with incredible precision and meet even the tightest requirements for tolerances.

Developing your LSR mold is usually the most expensive part of developing a liquid silicone rubber part. It takes expertise and patience to create an aluminum tool mold that will hold up to the high temperatures of the LSR molding process and provides you with a molded product that meets your specifications.

However, there are some things that make the production of an LSR mold easier, compared to a traditional injection mold. First, there is no need for a highly polished finish for liquid silicone rubber products. Also, since the material readily deforms and resumes its original shape, there is no need to worry about proper draft angles for ejecting the solidified product.

With LSR presenting many challenges in the molding process, a high degree of precision is expected and required for every mold we build. Our molds deliver a high level of efficiency and productivity, while providing excellent value throughout the life of the tool. We’re one of the few companies in the china offering waste-free LSR molds utilizing our own proprietary cold runner system. Tools are built to imperial and metric standards.

Our highly skilled staff excels in translating complex 3D part geometry into state-of-the-art injection molds. Our customers are comfortable knowing they’re working with a high level mold builder whose expertise goes far beyond simple flat parting line tools. Although we specialize in liquid silicone molds for medical applications, Anpllocnc serves many other industries, including dental, aerospace, automotive, and consumer products.

Liquid Injection Molding

Liquid Injection Molding (LIM), also referred to as Liquid Silicone Rubber (LSR) molding, is an injection molding process that uses a high viscosity liquid in two parts that is mixed with a platinum catalyst to enable a much faster cure rate compared to the injection molding of high consistency (HCR) rubber. The faster cure rate makes it ideally suited for high-volume manufacturing. LIM/LSR molding is a closed system of molding, so the uncured raw material never comes into human contact. This molding process is ideal for high purity applications such as in the medical, biopharmaceutical, food processing, dairy, and semiconductor industries.

The liquid injection molding/liquid silicone rubber molding process is ideal to produce complex designed parts such as three-dimensional configurations, parts with multiple thicknesses, undercuts, and high-volume overmolding. At Anpllocnc, we have taken the manufacturing process of LIM/LSR molding to a new level through our engineered quality system. This system provides our customers with a level of quality that is engineered into the process from the beginning of your project. Anpllocnc welcomes low-volume prototype and development quantities to high volume production while producing high purity, precision tolerance parts for a wide range of applications.

Features & Benefits of LSR Injection Molding

Liquid Silicone Rubber (LSR) is a versatile material that is flexible, cheap, and can resist chemical reactions. Hence, making it ideal for machine parts, household appliances, medical equipment, etc. Injection molding is a high-tech process that has revolutionized the rubber manufacturing process and enabled us to produce far more complex designs in larger quantities than were previously impossible.

High Production Volume

We can handle LSR components of all volumes, and create cost-effective, automated solutions to meet your needs.

Low Risk Of Contamination

Since the part fabrication process occurs in a “closed system” there is a very low risk of the operator or environment contaminating your part.

Easy To Automate

LSR part production with injection molding is very easy to automate compared to other methods of creating liquid silicone rubber parts.

Produces Less Waste

LSR injection molding does not produce scrap “flash,” because it can be used with flashless molds. This helps reduce waste and cost.Beyond this, liquid silicone rubber itself has some beneficial characteristics which may make it a good choice for your product.

Safe And Food/Medical Grade

LSR can be used to manufacture food-grade and medical-grade components, since it’s clean, inorganic, tasteless and resists bacterial growth.

Biocompatible

Liquid silicone rubber is compatible with human tissue and bodily fluids.

Electrical Insulation

LSR is an excellent electrical insulator, even compared to HCR and solid silicone.

Transparent

LSR is completely colorless and transparent, which opens up a lot of unique possibilities. It can also be pigmented during the injection process.

Chemical Resistant

Liquid silicone rubber resists common acids and alkali, water, oxidation, and some organic solvents.

Heat-Resistant

Liquid silicone rubber can withstand both high and cold temperatures without deformation or damage.

Injection Molded Silicone Parts

Anpllocnc Silicone Injection Molding is the best way to manufacture high precision silicone parts, especially for medical applications. Thanks to the CNC automation and closed system features of injection molding, you will be very satisfied with the quality performance of injection molded silicone parts.

Industries And Applications

Regardless of the industry, our liquid injection molding cells allow for the production of liquid silicone rubber parts or components that must withstand extreme conditions and make your products more effective. Industries and applications include:

Why choose to cooperate with Anpllocnc?

Class 8 Clean Room

Class 8 cleanroom injection molding is capable of providing you with high-quality, low-pollution plastic products.

Quality Control

Equiping with precision processing and production equipment, and strictly adhere to the quality control processes of ISO9001 and ISO13485 to ensure quality control.

Professional Engineering

Our professional Mold Design Team provides reasonable solutions that help reduce customer development and tool-making costs.

Precise Manufacture

Our world-class production and testing equipment provides a strong guarantee for the precision of your products.

Project Management

Our Bilingual Project Engineers with many experiences ensure smooth project operations and communication.

Learn More About Silicone Injection Molding

No posts found!

Quote online

Contact Anpllocnc for Custom Liquid Silicone Rubber Injection Molding Products

Your program: whether medical or consumer, complex or simple, multiple parts or a single part, low volume or high volume, we want to help make your program a success. We offer customized validations -- from Level 1 (meets print) to Level 3 (full medical IQ/OQ/PQ).