Insert Molding Service

As part of the injection molding service at Anpllocnc, we provide Insert molding from low volume production to high volume injection molding production requirement. It not only provides an injection molding option to have a part more precisely & tidy, but also being more cost efficiency, as without 2nd operation by post assembly or heat staking. During all the plastic injection molding projects we went through, we have ever worked on many insert-molding projects, and got rich experiences from them. With our professional & rich experience, we will take your insert molding projects successfully into the market.

- Custom solutions

- Assistance with material selection

- Full engineering services from art to part

- Trusted supplier to some of the world’s largest OEM’s

Insert Molding From Anpllocnc Custom Plastic Injection Molding And Manufacturing

Established in 2022, Anpllocnc is a Unique Contract Manufacturer specializing in “Technical Injection Molding Services” such as Multi-shot Molding, IMD (In-Mold Decorating), IMA (In-Mold Assembly), Vertical-Insert Molding and Medical Device Molding. We also offer standard Horizontal molding, with capacities from 28-ton / 1-ounce to 500-ton / 68-ounce. Anpllocnc is dedicated to utilizing robotics and automation to deliver “Value Added” services and lower “Total Part Cost”.

Our full service philosophy assures you that we can assist you from conception through production. We offer full engineering services including consultation, product design assistance, Design for Manufacturing (DFM) assistance, mold flow analysis, and mold design. Our Technical Services department offers In-House tooling capability along with local and off-shore sourcing of precision injection molds.

Our molding department offers competent processing of most all engineering grade and commodity resins, with experience in 2-shot molding, insert-molding, over-molding, hot runners and valve gates. As a value-added molder we include such services as ultrasonic welding, pad printing, hot stamping and assembly.

Our modern 44,000 square foot facility in china shenzhen was custom built after years of careful design and study. as the company’s manufacturing building, much experience went into the design and layout. Our Injection Molding and Tooling departments are second to none and the plant layout makes for an ease of material handling and flow of finished goods. All this just makes it easier to assure our customers “On-Time and Quality” products.

We Simplify The Manufacturing Process

We offer complete custom insert molding services from design to prototyping through production. All products and services are designed for manufacturability. The company is equipped for high-volume production with high-speed reel-to-reel capabilities, fully-automatic, high-cavitation production, and in-line automated welding and testing.

With insert molding, what is typically used to require a complex assembly can be produced in a single insert molded part saving our customers assembly time, labor and money.

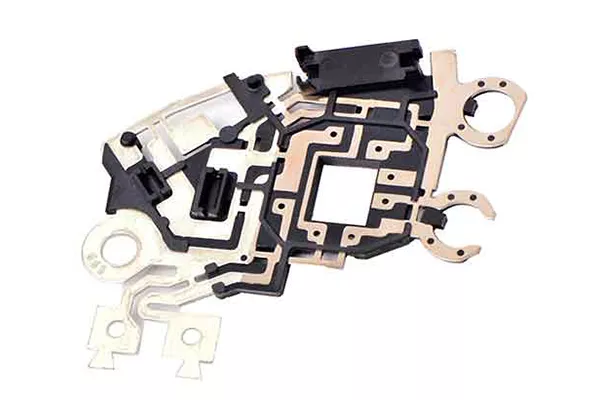

We use a process called “reel-to-reel” or “Continuous Strip Molding”. This process takes reels of metal inserts and mold miniature plastic forms, in any configuration, that are blanked out and assembled to your product.

We offer full in-house automation design, implementation and maintenance.

We Save Time And Reduce Costs

Through all phases of the project, we use Advanced Product Quality Planning (APQP) to ensure maximum efficiency in high volume production. Reel-to-reel press operation allows a seamless transition from our manufacturing floor to yours. In-house tool maintenance insures maximum production efficiency and tool life.

Through our extensive sourcing capabilities, we can more efficiently fulfill your requirement for close tolerances, and deliver attractive, durable, plus dimensionally stable insert molded products.

With insert molding, you have an accurate, repeatable process and lower part count. You have design flexibility and reliability, which reduces assembly and labor costs and translates into cost savings for our customers.

Custom Insert Molding Capabilities

- Insert

- Overmolding

- Horizontal Clamp – Horizontal Injection

- Vertical Clamp – Horizontal

- InjectionVertical Clamp – Vertical Injection

- Horizontal Clamp – Vertical Injection

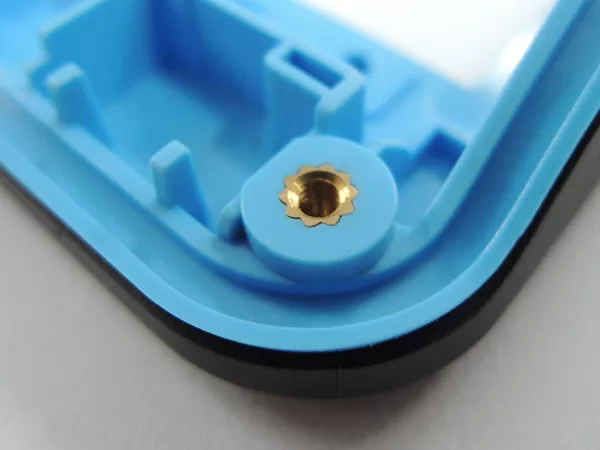

- Threaded Inserts – Brass and Stainless Steel

- High Tolerance Bushings

- Insulated Copper Wire

- Electrical Connectors

- Die Stamped Shapes

- .025 Steel Wires

- Shafts and Bars

- Copper Coils

- Chain Links

- Fiber Belts

- Blades

- Keys

28 to 600 tons

- 1 to 3 oz.

- 1 to 32

- Up to .5 in.

- Mold Sampling

- Conformance to Dimensions

- First Article

- ABS

- PC/ABS

- PP

- PA+GF

- POM

- Nylon

- PS

- PE

- PMMA

- PVC

- PLA

- PC

- PA6

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel

- Titanium

- Nickel

- Other Special Materials

- Material (Test Bars)

- Samples

- MRP System

- Critical Process Monitoring

- Cost Analysis

- Part Design Assistance

- Model Fabrication

- Prototype Injection Molds

- Production Injection Molds

- Plastic Parts Machining

- Warehousing

- Distributing

- Sonic Welding

- Inserting Ultrasonic Inserts

- Tipping

- Hot Stamp Decoration

- Assembly

- CNC Machining

- Regrinding

- Packaging

- Labeling (High Speed

- Thermal Printer)

- Bar Coding

- Product Pack Out

- Shielding

- Plating

- Silk Screen Printing

- Pad Printing

- Quick Prototype

- 1 to 1,000,000 parts

- 2 weeks

- SPE (Society of Plastics Engineers)

- E2 (Manufacturing Resource Planning)

- BBB (Better Business Bureau)

- CAD

- CAM

- IGES

- DXF

- STP

Benefits Of Insert Molding

Stronger Parts

Complex parts are created through a “one-shot” process that produces stronger parts than other molder processes.

Durable And Flexible Solutions

Insert molding eliminates fastener wear and tear to increase the life of the part.

Cost And Production Time Savings

By replacing secondary operations and components with an insert molding process or component.

Affordable Tooling

Molds designed for vertical operation are generally less expensive than horizontal molds. The reduced setup time makes short runs economical.

Quote online

Trust Anpllocnc For Your Insert Molding Needs

At Anpllocnc, we have extensive expertise to deliver exceptional insert molding solutions. Our team of experienced engineers and technicians work closely with clients to understand their requirements and provide customized solutions tailored to their specific needs. We ensure strict quality control throughout the entire manufacturing process to deliver superior products that meet or exceed industry standards.

Contact us today to discuss your insert molding project and experience the quality and expertise that Anpllocnc has to offer.

What Is Insert Molding ?

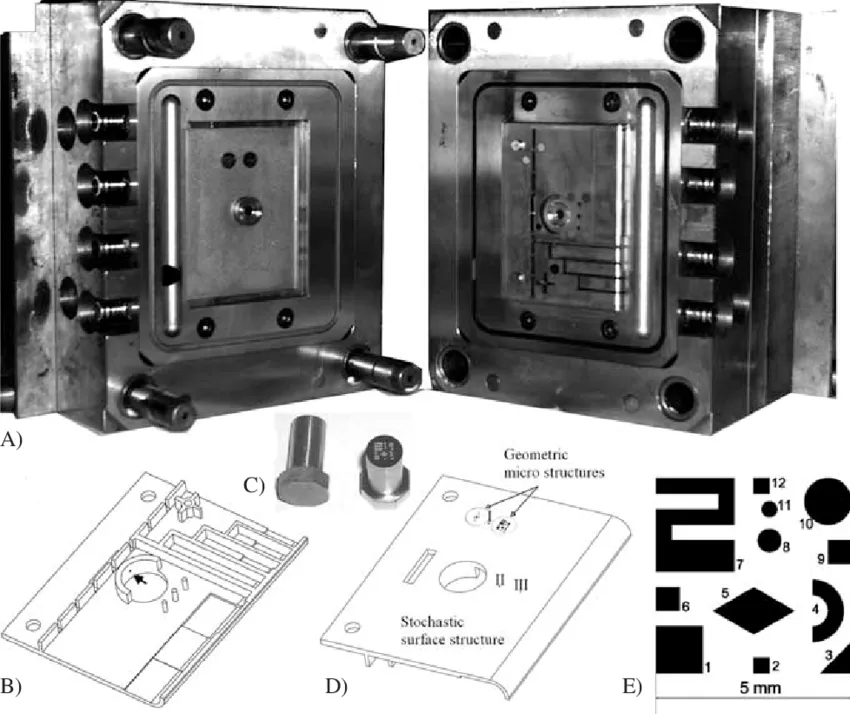

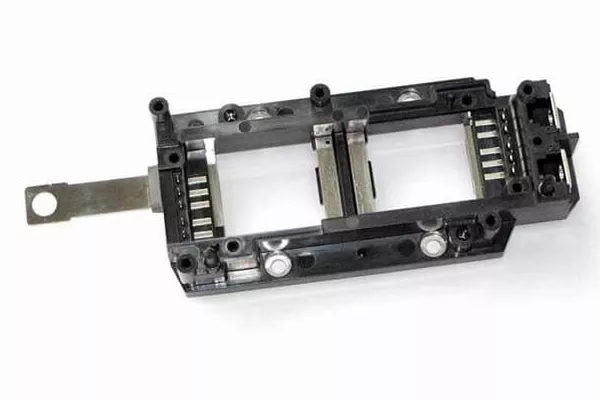

What is insert moulding: Insert molding is a manufacturing process in which a preformed part (usually metal) is remolded using a heated thermoplastic resin to produce a single unit, called metal insert molding. Molded inserts can be simple objects, such as rods, threads, or blades, but they can also be complex.

There are many cases where this manufacturing method is needed to enhance the mechanical properties of plastic parts. The plastic molding process requires very high precision to ensure the correct molding of the final plastic part. Even the slightest deviation can completely destroy the results, so very strict quality control procedures are required. In fact, the insert molding process is closely related to the interface between the machine and the tool. Some high-precision machines can meet even the most demanding requirements of precision and reliability that only insert moulding can meet.

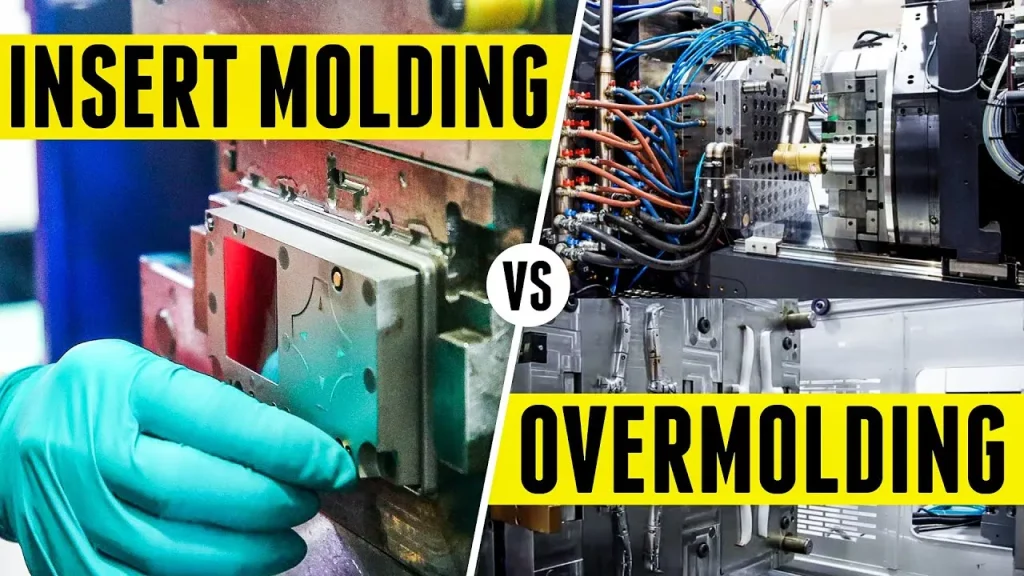

Insert Injection Molding vs Overmolding

Insert molding and overmolding are two distinctly different processes that produce their own unique types of products. The overmolding process takes place when one material is overmolded over a second material. The base layer is molded first and the additional plastic layer(s) are molded over and around the original part. This results in a single finished product. Overmolding creates a strong finished product with long service life and enhanced safety features.

Conversely, insert injection molding occurs when insert injection materials are injected into the mold cavity prior to plastic injection molding. The resulting product is a single piece with the insert encapsulated by the plastic. Plastic injection inserts provide a fast and cost-effective assembly process, producing parts with reduced size and weight.

What You Can Make With Insert Injection Molding?

Insert molding is a versatile manufacturing process that enables the production of complex and high-precision parts. At Anpllocnc, we have extensive experience in insert molding and have successfully produced a wide range of parts and products for various industries. For example, we have produced microelectronic components such as connectors, switches, and sensors that require high precision and tight tolerances. Additionally, we have manufactured automotive parts such as gears, housings, and brackets that require high strength and durability.

Industries Anpllocnc Works With

Explore Insert Molding News And Industry Updates

Find industry news, resources, insight into the insert molding process, and more, on the Anpllocnc blog:

No posts found!

Quote online

Contact Us for Custom Plastic Insert Molding Services

We have the insert molding experience and expertise to deliver the complex parts your project requires. Request a quote today or contact Anpllocnc for full-service injection molding for your unique application.