EDM Machining Services

Anpllocnc offers sink EDM services, wire EDM services, and small hole EDM services to manufacture extremely hard materials with tight tolerances, small internal radii, and complex shapes that cannot be machined by CNC.

- Get an online quote in less than 4 hours

- Tight tolerances of +/- .0001″ (.0025mm) are achievable

- Both Sink EDM, Wire EDM and Small Hole EDM are available

- EDM parts’ quality have accredited by more than 52 mold manufacturers

Our Services

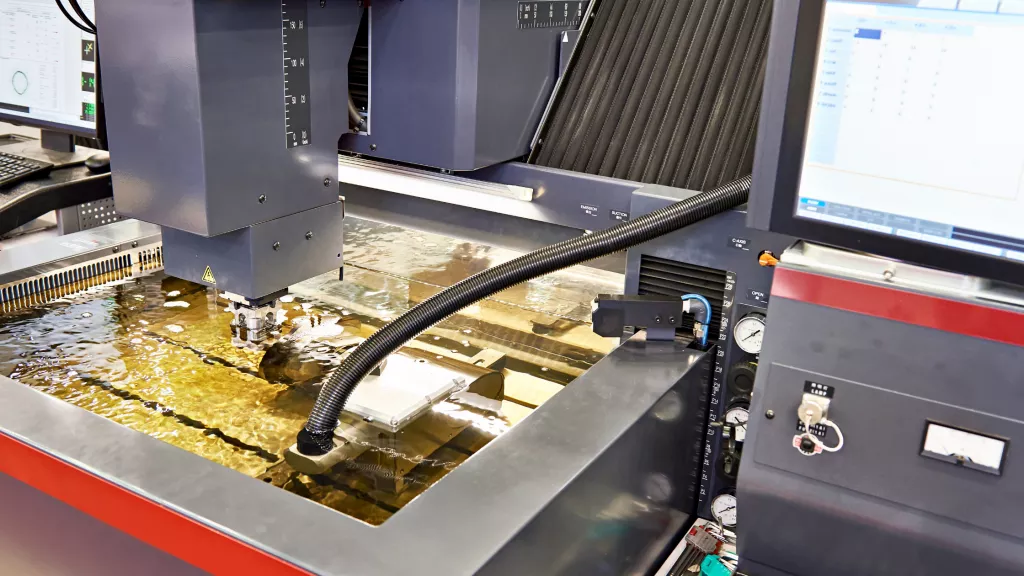

Anpllocnc is an AS9100 certified EDM service provider that provides high-quality electrical discharge machining services and has been working towards becoming an industry leader since its inception. Capabilities include wire EDM, small hole EDM drilling, conventional/sinker EDM and waterjet services. Our state-of-the-art equipment and programming software give us the tools to complete complex projects with tighter tolerances and faster turnaround times than other facilities. Anpllocnc’s sink EDM services, wire EDM services and small hole EDM services are ideal for machining extremely hard materials with tight tolerances, small inside radii and complex shapes that cannot be machined by any other method.

Anpllocnc’s EDM services cater to all aspects of manufacturing, including: medical, surgical, aerospace, missiles, defense, aerospace, satellite, tool and die, stamping and commercial. Anpllocnc has always gone above and beyond the standards of our customers and clients, and we have a reputation for fastest turnaround and extremely competitive pricing. Anpllocnc’s EDM staff are well trained and dedicated and strive to exceed customer expectations.

Get services now with the instant quote system

Anpllocnc produces high-quality EDM Machining parts in days instead of months. We are a factory with EDM Machining Services capabilities, giving you virtually unlimited capabilities to manufacture simple and complex parts. Our factories, including ISO 9001:2015, ISO 13485:2016 and AS9100D facilities, are highly skilled and get the job done. Get instant quotes using our newly developed online instant quote system.

Service Types

Electrical Discharge Machining (EDM)

Electrical discharge machining(EDM)simplified is a process of eroding a metallic workpiece with a reoccurring controlled electrical spark. Anpllocnc utilizes Wire EDM, Sinker EDM, and Small Hole EDM. Technological advances in controls, digital power supplies, dual feedback positioning and computing speed have dramatically improved the speed, accuracy, and reliability of the EDM process. Die Technology only utilizes high-accuracy and high-efficiency EDM equipment. Feature and positional accuracy deviation of less than 2 microns is common, and surface finishes of Ra 0.08 can be achieved in carbide and steel components. The EDM process generally does not introduce stress into the workpiece and provides a burr-free, clean surface.

Sinker EDM Machining Services

CNC Sinker EDM Machining, also known as Conventional EDM, Die Sinking EDM, Plunge EDM, or Ram EDM, is a sophisticated process that enables the creation of intricate shapes without introducing stress into electrically conductive materials. Our CNC Sinker EDM machines offer low-risk machining solutions, making them ideal for producing complex components with exceptional accuracy and reliability.

We are ISO 9001:2015 certified and offer standard, as well as high precision tolerances as tight as 2µm (0.0001″) for an array of industries and applications.

Small Hole EDM

Small hole EDM refers to a machine or machining process used to “drill” holes through a metallic workpiece. The electrode is typically a brass or copper tube. The workpiece material is typically hardened steel or carbide, or materials that are difficult to machine utilizing conventional means. Small hole EDM is often used to make a thread hole for wire EDM and has applications far beyond. Anpllocnc’s small hole EDM equipment has the capability to machine holes as small as Ø.008” and up to Ø.250”. This equipment has the capability to orbit the electrode for diameter and depth control, as well as the ability to change guides and electrodes autonomously. This equipment is fast & efficient for all metallic workpieces.

Wire EDM Machining Services

At Anpllocnc, we pride ourselves on being industry leaders in CNC wire-cutting EDM services. Our state-of-the-art EDM capabilities enable us to accommodate projects of any size and complexity, ensuring timely delivery without compromising on quality. We have invested in cutting-edge technology and skilled professionals to guarantee the finest results for our clients.

As an ISO 9001:2015 certified company, we offer both standard and high precision tolerances, achieving an impressive 2µm (0.0001″) precision. Our services cater to a diverse range of industries and applications, including die makers, mold builders, and part manufacturers worldwide

Capabilities

- Wire EDM

- Hole Starter EDM

Up to 15”

Up to 23”

Up to 18”

- ±0.005” Typical

- ±0.0002” Close Work

- Specific Tolerances Evaluated on a Per Project Basis

- Alloy Steel

- Aluminum

- Brass

- Copper

- Hastelloy

- Stainless Steel

- Carpenter Custom 455

- Carpenter Custom 465

- All Alloys

- Tantalum

- Titanium

- Tungsten

- Assembly

- Engraving

- Heat Treating

- Laser Marking

- Cleaning

- Passivation

- Polishing

- Prototyping

- TIG Welding

Brown & Sharpe CMM

Prototype

Low Volume

High Volume

Blanket Orders Accepted

- Quoted on a Job by Job Basis

- New Projects – 8 Weeks Typical

- Repeat Orders – 4-6 Weeks Typical

- Actual Lead Time Dependent on Volume & Complexity

Our services are delivered with high precision and consistency

The crowning glory of our EDM machining services lies in its extraordinary precision. Be it an intricate design or a large-scale project, our EDM machining services guarantee the utmost accuracy, making us the go-to choice for industries where precision is non-negotiable.

What is Electrical Discharge Machining?

Electrical Discharge Machining (EDM) is a manufacturing process that allows for the creation of complex shapes made from very hard materials and to very tight tolerances

Also called spark machining or spark erosion, EDM uses electrical discharges (sparks) to remove material from a workpiece.

The tool and the workpiece do not ever actually make contact, but they are placed into a dielectric (insulating) liquid. Voltage builds up in between the tool and the workpiece until the electric field becomes stronger than the dielectric.

When it does, a spark channel forms and the intense temperature and pressure cause a small amount of material to be vaporized and eroded from the workpiece.

EDM is perfect for applications that require the creation of intricate details or complex geometries such as in the fields of aerospace, automotive, defense, extrusion, electronics, food and beverage, medicine, and stamping.

Another aspect of of EDM is metal disintegration machining. During metal disintegration machining, manufacturers use electrical discharge machines to disintegrate broken tool parts stuck inside workpieces. Examples of these tool parts include studs, taps, drill bits, and bolts. By removing them from the center of a workpiece, manufacturers can recycle or reclaim the workpiece material.

Advantages

Tight Tolerance

EDM offers exceptional profile accuracy, with tolerances as tight as ±0.0001″ in easily obtainable.

Flexibility

EDM can create shapes and contours that other types of machines cannot.

Materials

EDM can be used on any conductive material, whether it has been hardened or not, including stainless steel, titanium, tungsten, copper, carbide, and tool steels.

Prototyping

Because of the speed with which designs can be updated, EDM is suitable for a variety of rapid prototyping applications.

Precision

EDM is a precision machining process with no cutting force applied to the workpiece. It allows producing finely detailed parts that would be impossible to achieve with conventional cutting methods.

Finishing

The surface of a piece machined with EDM can be as smooth and consistent as 4Ra without polishing, eliminating the need for secondary operations in many applications.

Distortion

EDM is suitable for cutting hardened materials. Forms can be machined after heat treating is complete, eliminating the problem of distortion caused by heat treat.

Production

EDM offers a cost-effective, highly repeatable method of producing multiple complex parts. Our EDM equipment supports “light-out,” round-the-clock operation, so DEK can deliver your parts faster.

Our Commitment to Quality Assurance

We are committed to staying at the forefront of technological advancements in the EDM industry. To ensure this, we consistently invest in acquiring new equipment with cutting-edge features and capabilities, allowing us to excel in both wire and sinker EDM services.

we employ state-of-the-art CMM systems and other automated inspection technologies. These systems enable us to inspect components with unparalleled precision, ensuring that the finished parts not only meet our customers’ expectations but also exceed market requirements.

- ISO 9001:2015 certified

- Coordinate measuring machine

- Auto & Manual QC

- Zero-Defect Shipments

Applications

- Tooling components for precision stamping dies, molds, & special machines

- Production of miniature precision components

- High precision components for automation & robotics

- Micro machining components for medical and electronic uses

- Difficult to machine materials including titanium, carbide, exotic alloys, tungsten, MP35N

Hard and Brittle Materials? We can meet your needs

Our EDM machining service simplifies the challenge of working with robust materials. We successfully machine hard and difficult-to-machine materials such as titanium, tungsten carbide, and hardened tool steels. Furthermore, materials too brittle for traditional methods are no match for our EDM machining service, pushing the boundaries of design and manufacturing possibilities.

Minimal Residual Stress, Maximum Quality

EDM machining’s low thermal impact significantly reduces residual stress and distortion in the workpiece, a common issue with traditional machining methods. This ensures the integrity and superior quality of your final product.

Minimal Residual Stress, Maximum Quality

Ultimately, one of the most significant benefits of EDM machining is its low thermal impact. Unlike traditional machining methods, which can generate substantial heat and lead to residual stress and distortion in the workpiece, EDM machining operates at significantly cooler temperatures. This greatly reduces the chances of residual stress developing, effectively eliminating distortions that might compromise the product’s dimensions and overall integrity. As a result, the workpiece maintains its intended shape and structural strength, highlighting the superior quality of your final product. This distinct advantage, when combined with the extraordinary precision of EDM machining, ensures that every intricate design is realized with exacting detail, adding another layer of excellence to our EDM machining services.

contact us

Get An Accurate Quote For Your Next Projects

Whether your project is complex or simple, metal or plastic, you can get an accurate quote from our instant online quoting system and our team of engineers.