Customized Parts Service: CNC Milling and Turning Machine Shop in China Introduction: Industries need customized...

Read MoreCNC Turning Service

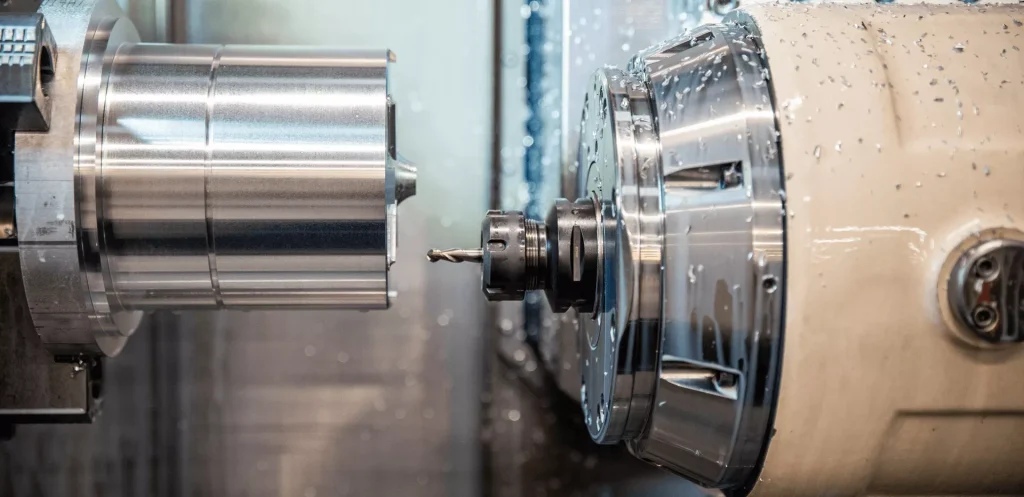

Anpllo can use the CNC turning process to make parts or product prototypes and mass-produce them. General threading, and CNC machining of round parts including shafts, worms, and balls.

- Instant Pricing & DFM

- Tolerances down to +-0.001mm.

- Parts as Fast as 3 days

Our Custom CNC Turning Parts Services

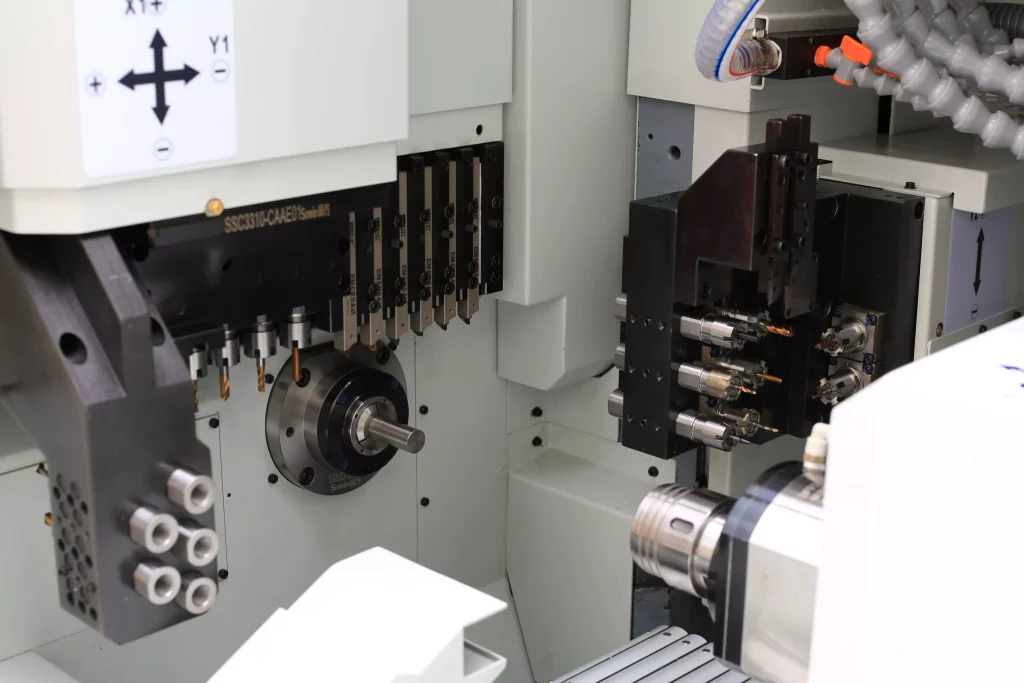

We offer a range of precision machining capabilities with a variety of computerized CNC turning centers that can be programmed to meet your exact specifications, no matter how simple or intricate. Whether you require a trial run, product prototype or large-capacity CNC production turning, you’ll get a fast turnaround on a quality product at a competitive cost.

In addition to multi-axis and multi-sided milling and turning machines, we also offer in-house CNC lathe machine turning services. Advantages of custom manufacturing parts using CNC lathe machining include reduced lead times, tight tolerances and exceptional material compatibility. From comprehensive CNC control capabilities and reverse engineering to CAD design and CAM programming services, we have the in-house facilities, ingenuity and knowledge to deliver the results you require.

Take advantage of the Anpllocnc on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, Anpllo produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity. You will get durable parts from flats to radial and axial holes, slots, and grooves as fast as one day.

Precision CNC Turning Capabilities

Boring

Drilling

Facing

Grooving

Knurling

Parting/Cutting

Threading

- External

- Internal

Turning:

- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

Secondary Grinding

- ± .0001 in

- Up to 15 in

- Up to 30 in

- ± 0.0001 in

- ± 0.0004 in

- Optical Comparator

- Coordinate Measuring Machine

- Granite Surface Plates

- Microscopes

- Hardness

- Non-Destructive

- Magnetic Particle

- Chemical Property Verification

- Mechanical Property

- Verification

- Cleanliness

- Rapid Prototype

- Low Volume Production

- High Volume Production

- Short Run

- Long Run

- Min: 1

- Max: 250,000+

- Blanket Orders

- Just-in-time

- KANBAN

- Alloy Steels

- Aluminum

- Brass

- Bronze Alloys

- Carbon Steel

- Copper

- Mild Steels

- Stainless Steel

- ABS (Acrylonitrile Butadiene Styrene)

- Acetal (POM)

- Acrylic

- Delrin

- Nylon

- PET

- Phenolic

- Polycarbonate

- Polyetheretherketone (PEEK)

- Polyethylene

- Polypropylene

- PolyTetraFluoroEthylene (PTFE)

- Polyvinyl Chloride (PVC)

- UHMW

Billets:

- Metals

- Plastic

Casting

Extrusions:

- Metals

- Plastics

Forgings

Molded Plastic Components

- Horizontals

- Verticals

- Turning Centers

- Hanwha XD38 CNC Swiss Lathe 1-1/2″ Bar

- Haas SL-30 4″ Bar & 18″ Chucking

- Haas SL-30 3″ Bar & 10″ Chucking

- Haas SL20APL w/ Robotic Loader 3″ Bar & 8″ Chucking

- Haas SL-20 2-1/2″ Bar & 10″ Chucking

- Hardinge Conquest 65 CNC 2-1/2″ Bar & 10″ Chucking with Live Tooling

- Haas HL-4 2-1/2″ Bar & 10″ Chucking

- Hardinge Conquest T42 CNC 2″ Bar & 8″ Chucking with Live Tooling

- Hardinge Cobra 51 CNC 2″ Bar & 8″ Chucking

- Hardinge Conquest 51 CNC 2″ Bar & 8″ Chucking

- Hardinge Quest 10/65 CNC 2-1/2″ Bar & 10″ Chucking

- Hardinge Talent CNC 2″ Bar & 8″ Chucking

- Haas SL-10 1-3/4″ Bar & 6″ Chucking

- Haas GT-20 1-5/8″ Bar & 8″ Chucking

- Hardinge Conquest 42 CNC 1-5/8″ Bar & 6″ Chucking

- Hardinge Cobra 42 1-5/8″ Bar & 6″ Chucking

- Hardinge Conquest CNC GTSP 1-1/16″ Bar & 4″ Chucking with Live Tooling

- Emco-Turn 345 CNC 1-5/8″ Bar & 6″ Chucking

- Haas Mini-Lathe 1-1/16″ Bar & 4″ Chucking

- Haas Mini-Lathe w/ Robotic Loader 1-1/16″ Bar & 4″ Chucking

- Three-jaw chuck

- Collet chuck

- Custom Fixtures Designed and Manufactured

- Balancing

- Bending

- EDM

- Laser Cutting

- Water Jet Cutting

- Honing

- Burnishing (ID & OD)

- Marking

- Engraving

- Laser Marking

- Sand Blasting

- Vibratory

- Thermo-Deburring

- Custom Packaging

- Labeling

- ANSI

- AS 9100 (Compliant)

- ASTM

- ARMS 9009:2013 Certified

- CSA (Compliant)

- ISO 9100:2008

- RoHS

- SAE

- TS

- AutoCAD (DWG,DXF)

- DXF

- Drawing Interchange Format, or Drawing Exchange Format

- IGES

- Initial Graphics Exchange Specification, ANSI file format.

- MasterCam (MCX)

- Portable Document Format

- STEP

- Standard for the Exchange of Product Model Data

- TIFF

- Tagged Image File Format

Features & Capabilities Of Anpllocnc CNC Turning

Anpllocnc provides precision CNC turning services. It works with various materials to deliver high-quality CNC turned parts. Here are some of its features and capabilities:

- High Volume Output. With the company’s advanced machines, it can deliver a high volume of parts/products. As such, you will be guaranteed timely delivery of the finished products.

- Rapid Prototyping & End-Use Manufacturing. The company has high-precision equipment and skilled technicians, so it is capable of providing rapid prototyping and end-use manufacturing. This means that your prototypes can be finished faster, as well as remain cost-efficient.

- Reliable Quality & Performance. When you choose Anpllocnc for your CNC turning services, you can expect to receive parts that are reliable and have good performance. It also provides machining solutions that suit the requirements of its clients.

- Short Lead Time & Production Cycle. With a wide range of CNC lathe services, the company can provide you with high-quality parts in a short lead time.

- Many Compatible Metals and Plastics. The company’s CNC lathe services are compatible with many different materials, including copper, stainless steel, aluminum, titanium, carbon steel, and brass. You can also use plastics such as ABS, PP, and PVC.

- Smooth Finishes & Tight Finishes. This company’s CNC turning services are known for creating smooth finishes and tight tolerances. It can also meet your specifications concerning dimensions, surface roughness, and materials.

Start Your Custom CNC Turning Parts production

Our concept is to make the best custom CNC turning parts from the beginning!

DFM Analysis and Design

An engineering team of 20 technicians is always ready to getprofessional suggestions from early-stage material seletion,custom prototyping design advice, to money-saving tips andtechnical reminders before CNC turning parts manufacturing, all the wayto end-use production.

CNC Turning Services

Before rapid CNC turning components, we will give you detailed quotation, CNC turning, testing, etc., and deliver in the shortest time. This way you can confirm the next steps and bring them to market.

Get CNC Turning Parts

The fastest parts can be obtained within 3 days for simple parts, and the fastest parts can be obtained within 7 days for complex parts. The specific time needs to be judged according to your rapid CNC turning parts drawings.

Your Full-Service CNC Turning Partner

Anpllo provides all necessary secondary milling and grinding operations offering customers surface treatments with CMM reports. Our Wire EDM, cutting, milling and custom fabrication services build upon turning processes to produce a huge variety of CNC machined parts. Value added services include assembly, coating, heat treating, welding, painting, plating etc.

Maximum Capabilities For CNC Turning

| Part size limitations | Metric units | Imperial units |

|---|---|---|

| Maximum part diameter | 431 mm | 17 in |

| Maximum part length | 990 mm | 39 in |

| Maximum swing over the carriage | 350 mm | 13.7 in |

| Maximum spindle through-hole | 40 mm | 1.5 in |

Tolerances

We follow ISO 2768 standards for CNC Turning.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

- Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing.

Contact US Online

Fast And Free CNC Quote

If you’re ready for a fast and free quote for your CNC Turning projects, contact Anpllocnc today and we will deliver one to you within 24 hours. Reduce production time, reduce waste, and reduce stress.

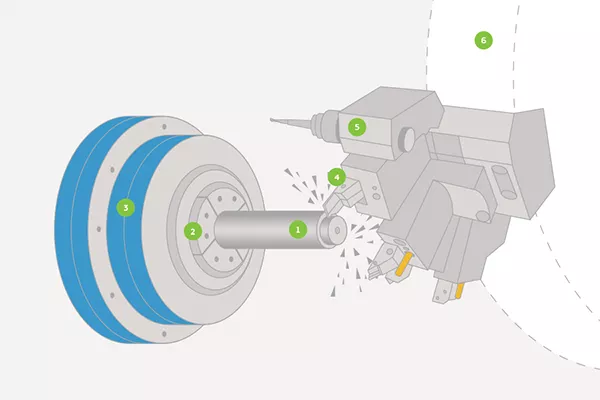

Basic Types Of CNC Turning Processes

The process range of CNC turning is very wide, which can be processed various types of rotary surfaces, such as external turning, internal turning, taper turning, parting, facing, boring, reaming, drilling, knurling, threading, grooving, etc.

O.D. and I.D. Turning – For machining precise cylindrical features. For machining precise cylindrical features. Turned parts can continue to be machined in depth, with visible tool marks (Tool used: General turning tool)

Parting and Grooving – For parting off, or cutting a “groove” profile in either the internal or external part of a part (Tool used: Parting and grooving inserts)

Facing – Flattening the face of the workpiece (Tool used: Facing tool)

Boring and Reaming – Enlarging or finishing of existing holes to obtain highly accurate diameters (Tool used: Boring and reaming tools)

Drilling – Remove materials to drill holes from the inside of a workpiece (Tool used: Drills)

Threading – Machining of threads by turning, may be done in either the internal or external area of the workpiece. (Tool used: Threading tools)

The Right Equipment for Any CNC Turning Job

Our lathes feature engine and CNC equipment, with bar feed and large swing capacity. Common applications of our processes include forgings, shafts, bushings, fixtures, fittings, and construction equipment, but we can produce nearly any part you need from prototyping to final design. In addition to CNC turning services, Anpllocnc also offers reverse engineering, CAD design, and CAM programming services.

Anpllocnc has invested in the equipment necessary for precise work, including a vertical lathe, four-jaw chuck fixturing and the latest computer software. We can work in virtually any material: alloy steels, stainless steel, brass and iron, just to name a few. Assembly and finishing services are also available. We accept parts drawings in several digital formats: SolidWorks, AutoCAD, STEP, .pdf, and .dxf.

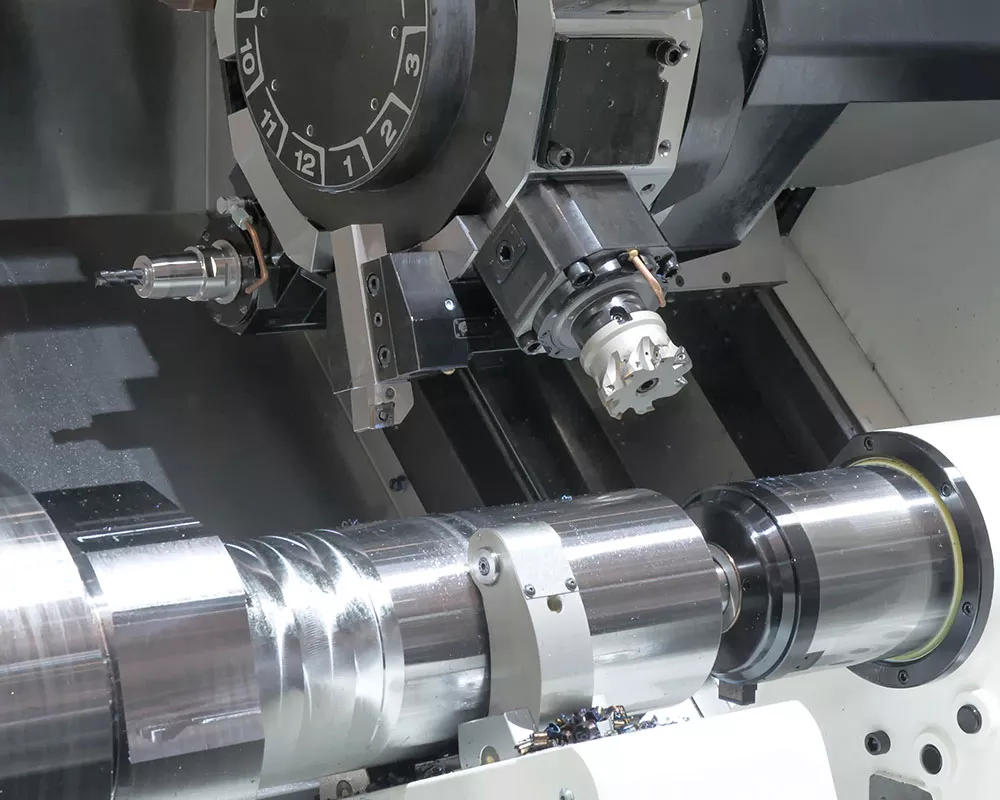

CNC Horizontal Turning

Anpllocnc offers CNC horizontal turning with the capability to produce parts weighing up to 950 lbs., up to 44″ in length and 25″ in diameter. We can also produce parts as small as 1/8″ wide, working to tolerances. With a 3-axis, live tooling-equipped turning center, our capabilities include internal and external threading, knurling, profiling and much more.

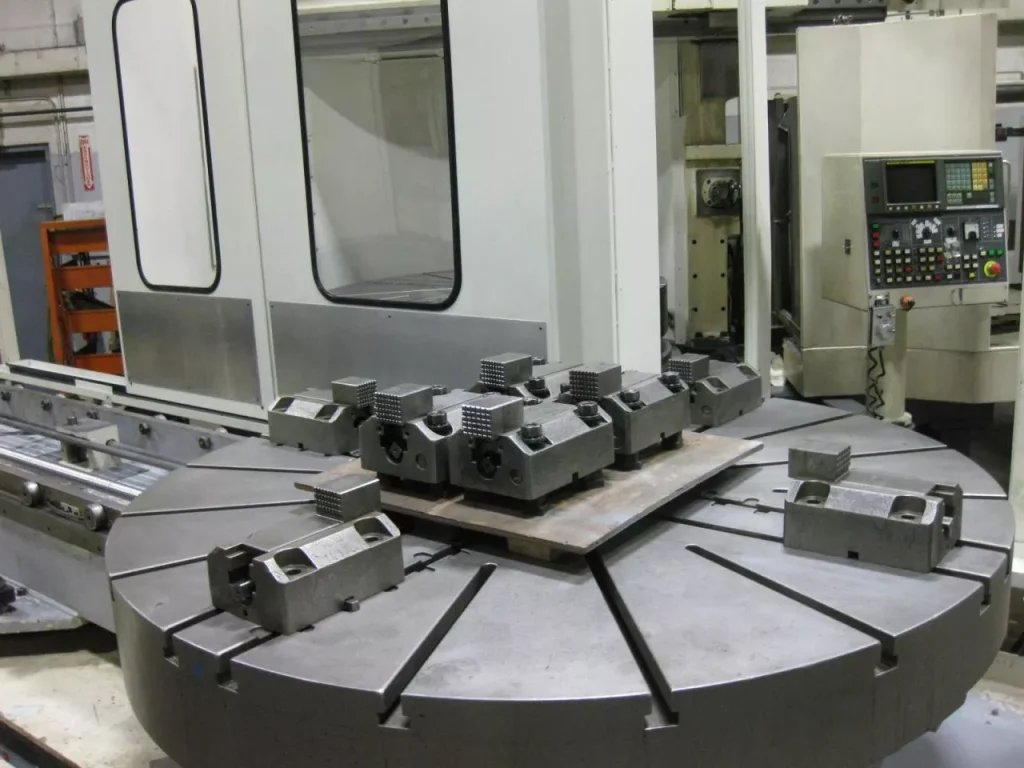

CNC Vertical Turning

Anpllocnc offers CNC vertical turning services for products in a wide range of industries—from construction and farm equipment to aerospace and defense. We produce precision machine components to tight tolerances with short lead times. Parts can be manufactured up to 21.5″ long, with a maximum diameter of 51″ and a maximum weight of 20,000 lbs. Our capabilities include contour and straight turning, internal forming, counterboring, pocketing and much more.

Design Your CNC Turned Part Today

Anpllocnc has the component experience needed for high-quality CNC machined medical devices, implants, and parts for the aerospace and defense industries.

Contact us to discuss your CNC turning project or request a quote to design your custom component today.

Why Anpllocnc For Turning Service

Rapid Lead Times

Equipped with advanced CNC machines, we can deliver rapid CNC-turned parts in as fast as 3 days with high accuracy.

Great Scalability

Our CNC lathe services are ideal for rapid prototyping or low-to-high volume production of 1-10,000 parts.

High Precision

Our tolerances range from +/-0.001″ – 0.005″, which is greatly influenced by the part’s geometry and material type.

Available Materials

Choose from over 50 certified metal and plastic materials suitable for CNC turning.

Extensive Experience

Our engineering team owns vast experience from numerous previous projects, they are proficient in managing intricate and accurate components in various industries seamlessly.

Various Surface Finishes

Abundant choices for surface finishing on solid metal or plastic turned parts in accordance with all critical design specifications.

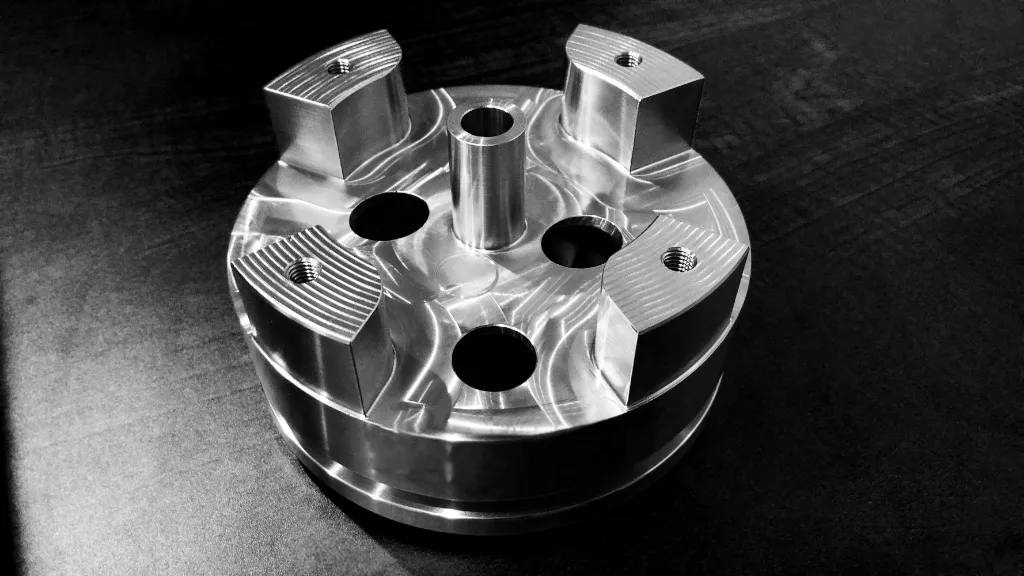

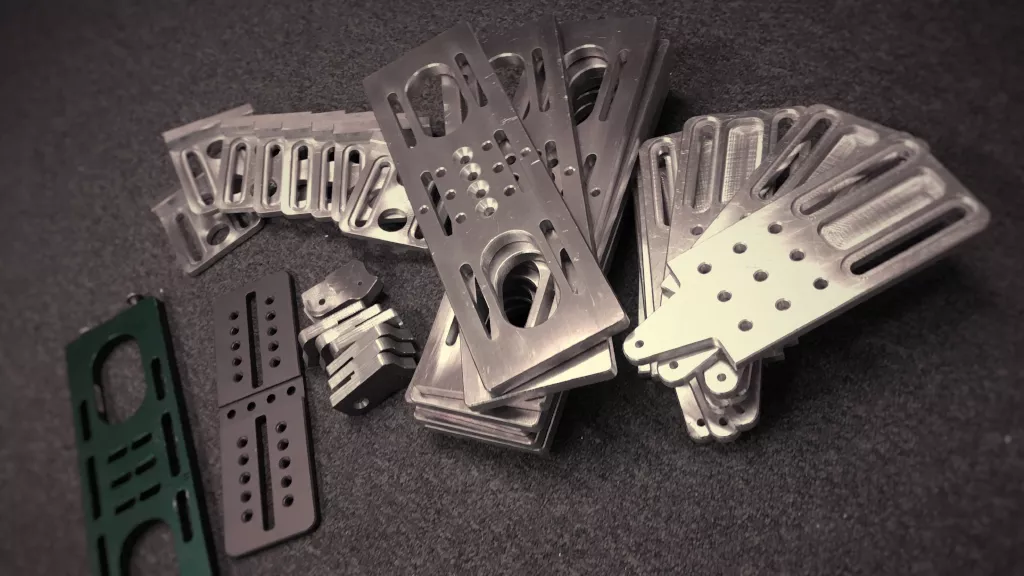

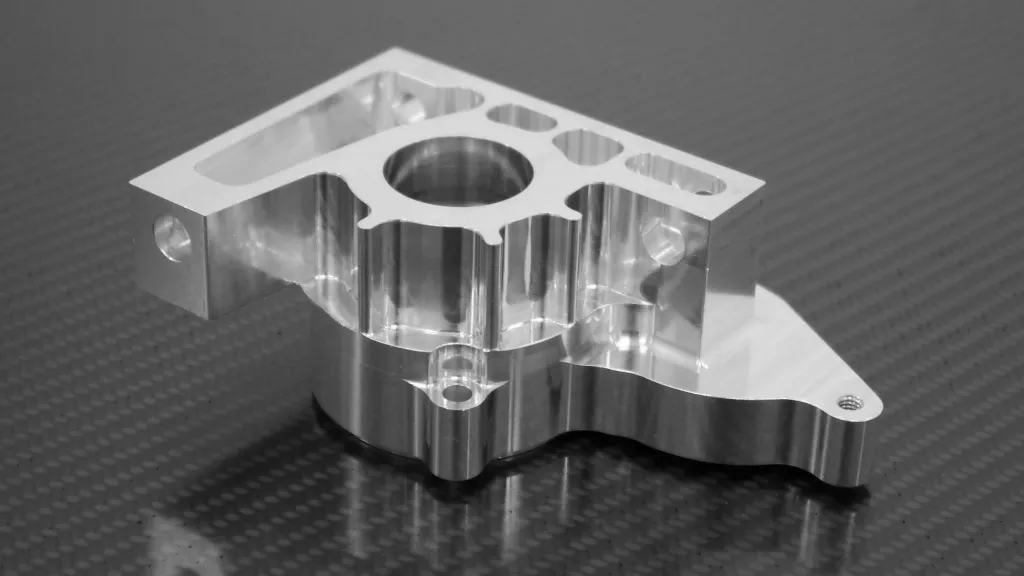

Gallery of CNC Turning Parts

Check out our extensive gallery that shows precision turned prototypes and parts from our valued customers.

Our Other Manufacturing Services

CNC Machining Service

Parts In As Soon As 5-Days,Wide Variety of Materials,Finishing Options & Scalability,Tolerances down to ±.0008 in (0.020 mm)

CNC Milling Service

Tolerances down to ± 0.004 in (± 0.01 mm) achievable – less on request.From 3-Axis Mills to 5-Axis Complex Parts.Lead times from 5 Business Days.

Rapid Prototyping Services

Choose from CNC machining and sheet metal, get free interactive designs for manufacturing feedback on every quote, and master physical prototypes in days to quickly revise designs during development.

Low-Volume Manufacturing Service

Anpllo provides a one-stop service for small-batch production of CNC machining, milling, turning, sheet metal processing, etc.

Anpllo Quality Assurance

- ISO9001 certified Manufacturing Partners on request

- Inspection report included in every order. Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Strict NDA agreements with all Manufacturing Partners

- Manufacturing Partner performance tracking on lead time and quality

Our CNC Turning For Various Industrial Applications

Anpllo’s cost-effective and reliable CNC-turned parts see great use as crucial pieces in equipment for medical, consumer goods, and automotive fields, and more.

Frequently Asked Questions

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture parts for automotive, aerospace, medical, and other industries.

We can turn parts with diameters ranging from 0.5mm to 65mm for stock bars. Our turning capabilities can reach up to 3000 mm for billets.

Yes, our CNC turning services include plastic parts manufacturing. We can produce small or large batch prototypes and production parts from various engineering-grade plastics. Choose from our extensive range of plastic materials and upload your design file to get custom plastic components.

CNC Turning Resources For Engineers

What is Anpllocnc’s CNC Turning Service?

What is Anpllocnc’s CNC Turning Service? Learn more about CNC turning with our guide to...

Read MoreOEM CNC Turned Parts Guide. Understanding, Solutions, and Sourcing

OEM CNC Turned Parts Guide. Understanding, Solutions, and Sourcing As the global economy grows, various...

Read MoreMore about titanium metal

More about titanium metal Titanium is a metallic mineral known in nature. Please don’t consider...

Read More

For Businesses Of All Sizes

Get in touch with our team to access these services:

- Add Anpllo as a vendor

- ISO 9001, material certifications, test reports and full dimensional reports

- Non-disclosure agreements

- Sample verification program (learn more)

- Dedicated account manager

or email us at [email protected]

Get A Instant Quote Today

Precision CNC Turning Service Provider

At Anpllocnc, we provide precision custom machining at competitive prices to various organizations and industries, including the U.S. Department of Defense.

With more than Ten years of experience, we've refined our processes, leading to quick turnarounds, on-time deliveries, fast communications, and minimal waste. Additionally, we adhere to our strict standards for quality, demonstrated by our ISO 9001:2015 accreditation and compliance with U.S. MIL-I-45208A standards.

Build your partnership with China One-stop on-demand custom manufacturing company by contacting us today to discuss your CNC turning needs.