Customized Parts Service: CNC Milling and Turning Machine Shop in China Introduction: Industries need customized...

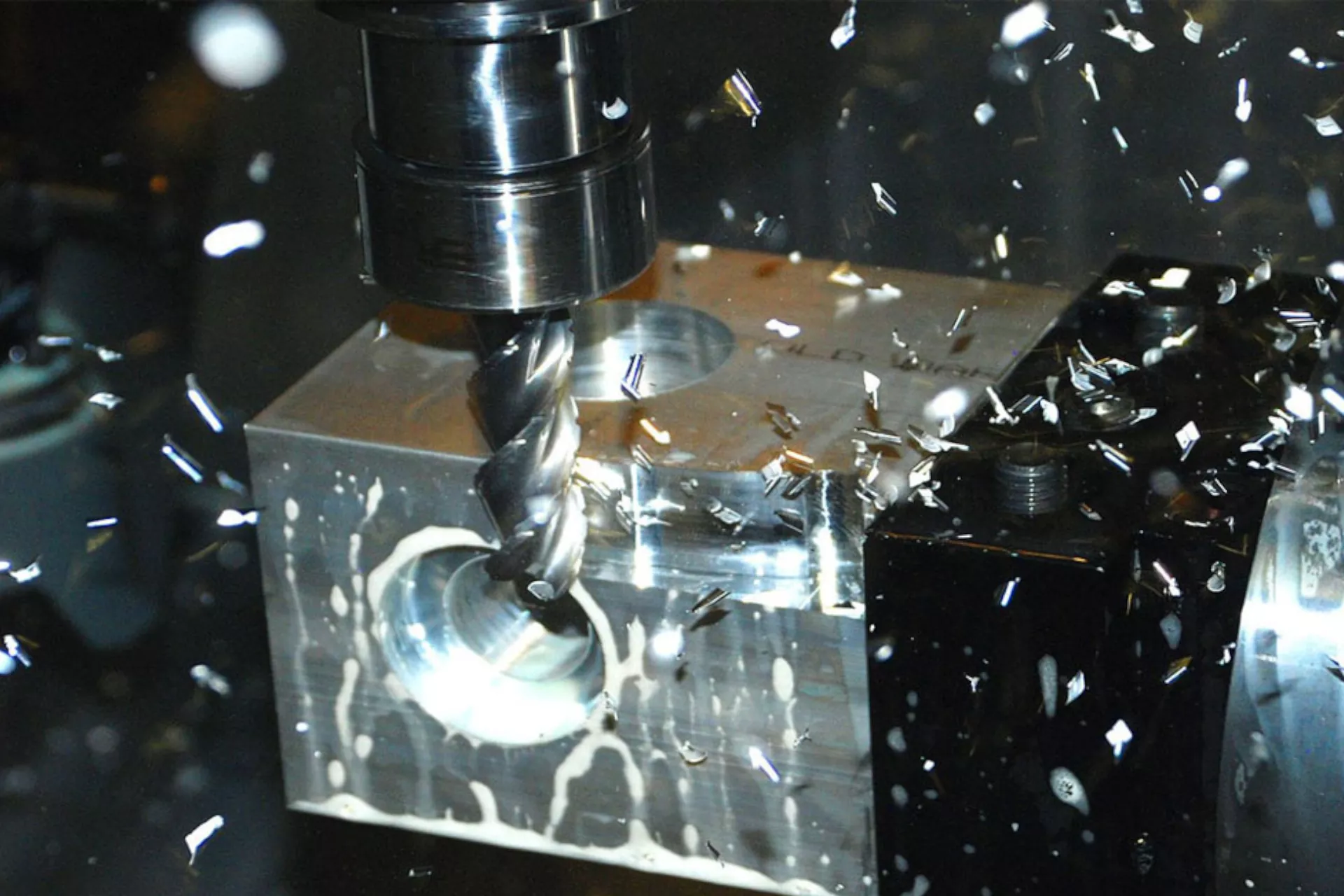

Read MoreCNC Milling Services

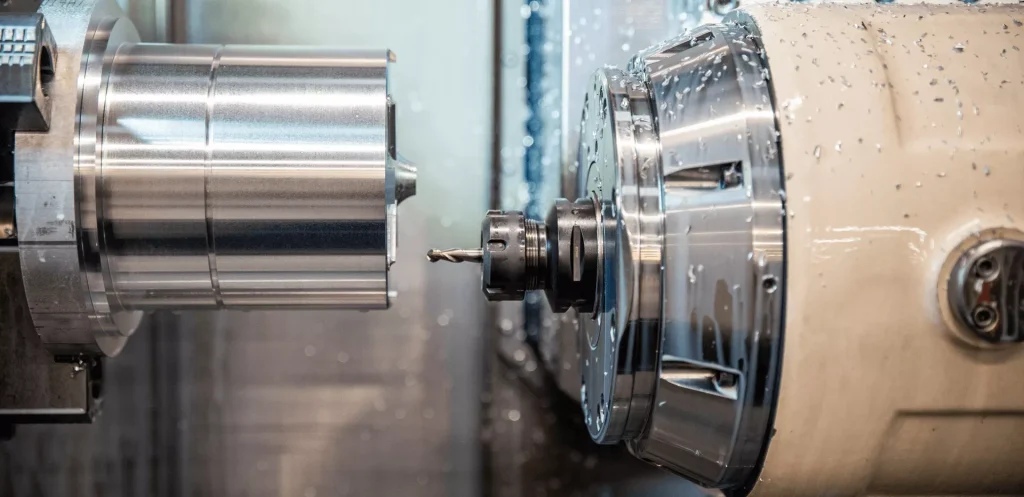

Anpllo provides CNC milling services for custom CNC parts of any specification, in any material.

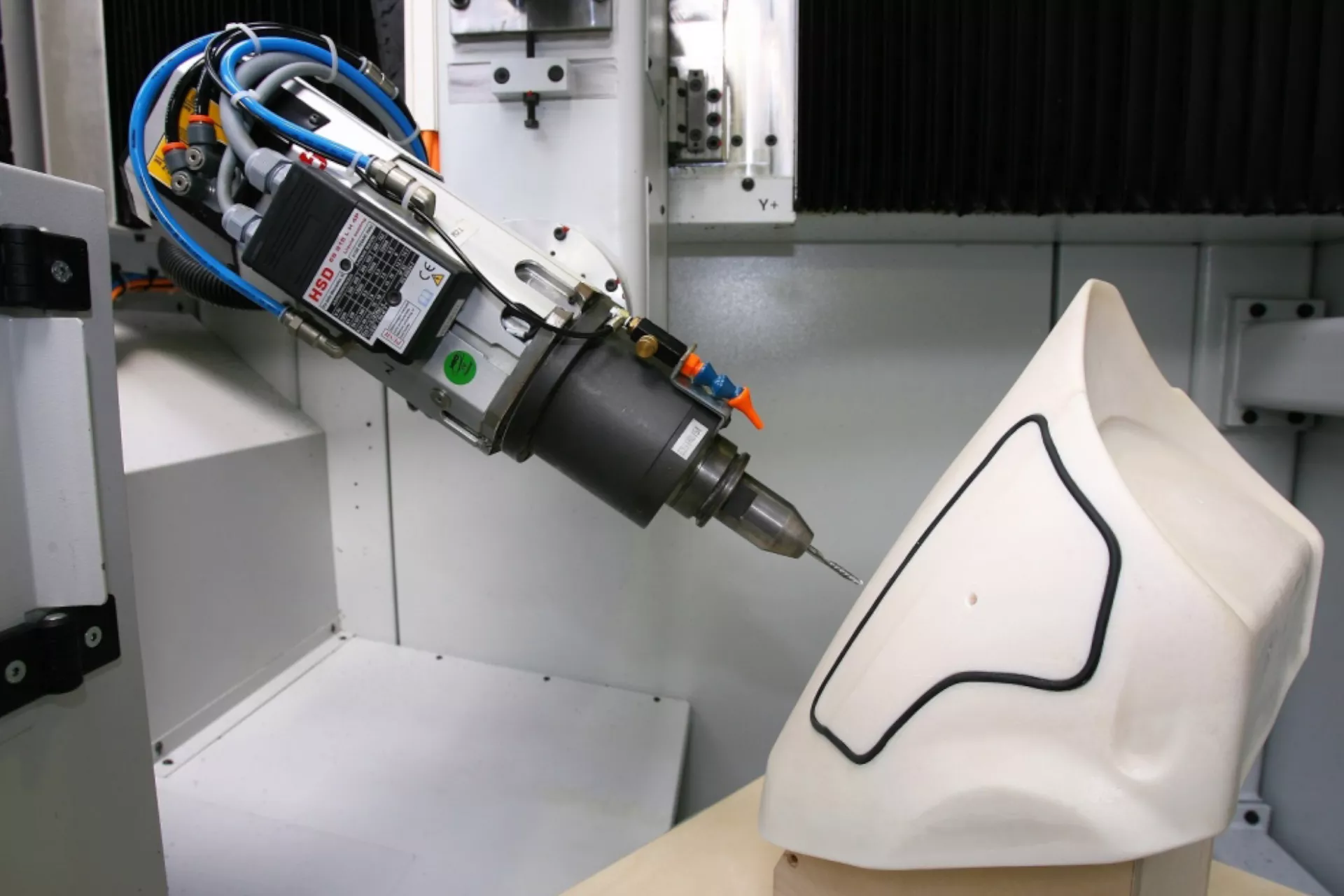

- 3-axis, 4-axis, 5-axis CNC Milling Services are available

- Rapid services, your parts can be shipped as fast as 3 days

- Competitive pricing

- CNC milling metal and plastic are available

- Tolerances of ±0.005mm are achievable

Our Service

Anpllo cnc is a trusted provider of precision CNC milling services to clients around the world and across a wide range of industries. The experienced team has a deep understanding of the latest manufacturing technologies and design concepts, which they use to develop the best processes to mill tight tolerance components in a cost-effective manner. We have an ISO-certified custom CNC machining facility in China, which enables us to provide quality parts at very competitive prices.

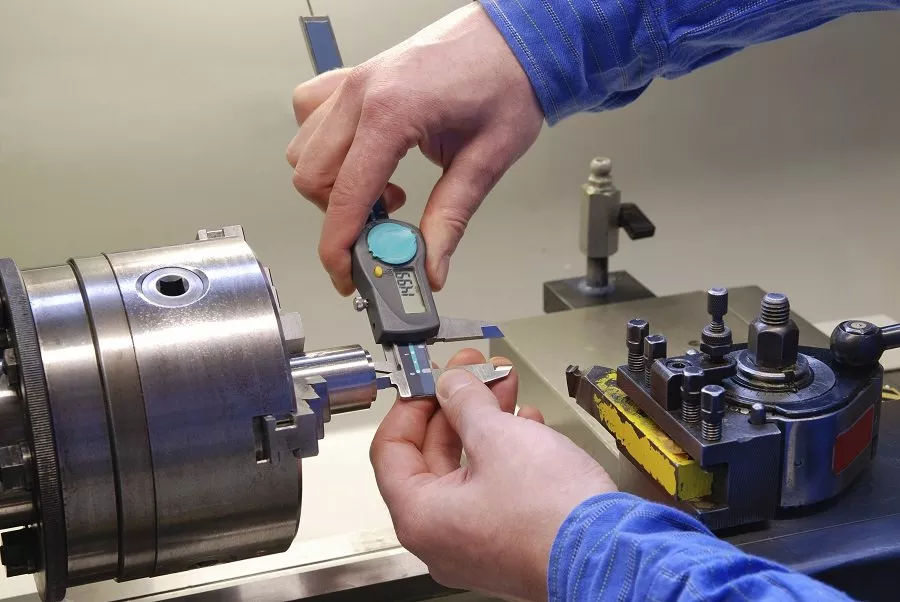

We provide turnkey solutions so that our customers can maximize inventory turnover while minimizing inventory and realize their custom needs with Anpllo cnc’s technical and Kanban expertise. We also have a dedicated quality control team that tests and ensures that all CNC machined parts meet customer requirements and required standards and regulations.

Whatever your industry, Anpllo cnc provides instant pricing, on-demand delivery times, and design for manufacturability feedback for materials and manufacturing processes for your custom CNC milled parts. Get your instant quote today.

3 Axis,4 Axis, 5 Axis Milling Services

According to your unique requirements, budget, and timeline, we will choose a best way for milling. For expert advice, please contact our professional sales team to find the right match for your needs.

3 Axis CNC Milling

4 Axis CNC Milling

5 Axis CNC Milling

Capabilities

The following features of our CNC milling service enables us to meet your requirements efficiently.

- Design

- Development

- Manufacturing

- Boring

- Broaching

- Counterboring

- Countersinking

- Drilling

- Pocketing

- Profiling

- Reaming

- Tapping

- Thread Milling

- Honing

- Broaching

- Shaping

- Cutting

- Min: ± 0.002 in

- Max: ± 0.0005 in

- Max: 60 in (1524 mm)

- Max: 30 in (762 mm)

- Max: 15 in (381 mm)

- 3,4,5Axis

- 4-Axis Fryer MC-60P Machining Center – 60″ x 30″ x 28″

- VMC 800 Bridgeport High Speed VMC – 30″ x 20″

- 610 XP3 Hardinge High Speed VMC – 30″ x 20″

- 480 Hardinge High Speed VMC – 20″ x 15″

- 3-Axis Fryer MC-50 Machining Center – 50″X x30″Y x 26″Z

- 3-Axis Millennium CNC VMC – 28″ x 13″

- Plain

- Swivel-type

- In-House Custom Fixtures to Meet Job Requirements

- Monel

- Stainless Steel

- 300 Series

- 400 Series

- 15-5 PH

- 17-4 PH

- Aluminum

- Copper

- Brass

- Bronze

- Carbon Steel

- Inconel

- Hastelloy

- Cobalt Chrome

- Titanium

- 2 RA (Mirror Finish)

- Profile Projector

- High Magnification

- Microscope

- Height Gauges

- Depth Gauges

- Granite Place

- Surface Profilometers

- Optical Comparator

- Coordinate Measuring

- Machine (CMM)

- Die Penetrant

- Ultrasonic

- Positive Material Identification (PMI)

- Annealing

- Anodizing

- Plating / Coating

- Heat Treating

- Passivation

- Tungsten Carbide Flame Spray

- Nitride Coating

- Etching

- Packaging

- AS 9100

- ISO 9001

- ISO 13485

- Nadcap (AC7004)

- Nonconventional Machining (EDM)

- Prototype

- Low Volume

- Small Run

- Medium Volume

- 1 – 12 Weeks

- Quoted on job by job basis

- Emergency services available

- Rush Services Available

- AutoCAD (DWG,DXF)

- BMP

- DXF

- GIF

- IGES

- JPEG

- SolidWorks (SLDPRT,SLDDRW,SLDDRT)

- .x_t Parasolids

- STEP

- TIFF

Start Custom Components Production

Our concept is to make the best custom CNC Milling components parts from the beginning!

Prototype Machining Manufacturing

Before the prototype is manufactured, we will give you a detailed quotation, CNC machining, testing, etc. Delivered in the shortest possible time. So that you can confirm the next steps and bring them to market.

Video Communication

After sample production confirmation, it is inevitable that there will be problems, such as drawing modification and high cost. Don’t worry. Our dedicated engineering team is ready to provide practical design advice and conduct video conferences on your CNC machined parts.

Mass Production

Every CNC machining production run is documented in detail, and photos and videos are transparently shared with customers. Video communication can also be used to check the production process. Provide information required by customers.

Ready to get started on your CNC milling quote?

Our experienced engineers can design the best machining process and select the right tooling based on the customer’s drawing to mill quickly, obtain a good machined surface, maintain tight tolerances, and ensure optimum quality. We can provide all types of custom CNC milled parts to meet the needs of your project. If you have problems completing your CNC milled parts, contact us and try to get a solution from Anpllo.

Advantages

- All CNC machining including milling is performed in-house at our well-equipped facility in china shenzhen.

- Multi-axis CNC machines coupled with advanced AutoCAD software and a team of skilled operators help us meet all project requirements effortlessly.

- Our well-maintained CNC milling machines enable quick production as CNC milled parts can be easily milled within minutes. This makes it more effective than additive manufacturing.

- Our facility is certified to ISO 9001: 2015. This shows our commitment to quality and adherence to best work practices.

- Our team works in a clean and well-equipped, temperature-controlled facility, and follows all the safety measures, which helps us assure the safety of people and surroundings.

- We have partnered with some of the trusted suppliers in the industry, which helps us assure the quality of materials. The materials are tested and inspected for quality before machining them.

- All CNC milled parts that leave our facility are checked for accuracy and perfection at every stage of manufacturing and they undergo multiple inspections before leaving the facility. This helps us assure ahigh level of accuracy.

Maximum Part Size For 5-axis CNC milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for all materials | 650 x 650 x 300 mm | 25.5 x 25.5 x 11.8 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

Maximum Part Size For 3-axis And 2-axis CNC Milling

| Size | Metric units | Imperial units |

|---|---|---|

| Max. part size for soft metals & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

Tolerances

We follow ISO 2768 standards for CNC Milling.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm |

- Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing.

General Tolerances

| Tolerances for Linear Dimensions(GB/T 1804-2000, class f) | ||||||||

| Dimension (mm) | 0.5~3 | >3~6 | >6~30 | >30~120 | >120~400 | >400~1000 | >1000~2000 | >2000~4000 |

| Tolerances | ±0.05 | ±0.05 | ±0.10 | ±0.15 | ±0.20 | ±0.30 | ±0.50 | —- |

| Tolerances for Angle Dimensions(GB/T 1804-2000, class f) | ||||||||

| Dimension (°) | ≤10 | >10~50 | >50~120 | >120~400 | >400 | |||

| Tolerances | ±1° | ±30° | ±20° | ±10° | ±5° | |||

Contact US Online

Anpllocnc Will Ensure The Quality Of The Milled Parts Quote. Our CNC Quotes Can Be Generated Instantly.

With over 10 years of high-precision CNC machining experience, Anpllocnc has the experience needed for high-quality CNC machined medical devices and implants, and parts for the aerospace and defense industries.Contact us to discuss your CNC milling project or request a quote to design your component today.

Your trustworthy professional CNC milling company

Gapless Communication

You can communicate seamlessly with our English and Spanish sales team, and your requirements will be transferred to the engineering team clearly

Positive Services

Positive after-sales service and solutions. Never shirk responsibility, our team will take the initiative to deal with problems

Fast Response

You can get a quick quote within 4 hours. And we offer fast CNC milling service, you projects will be send out as fast as 5 days or less

Save Cost

We will reduce your 40%-60% purchase cost by investing in the finest milling machines, improving production efficiency, and purchasing raw materials in bulk

High Precision

By hiring true professionals and not just standard workers to operate our CNC milling machines, to ensure you can get the high precision milled parts

Multi Material

More than 60 kinds of material can be chosen, including metal and plastic

Surface Finish

After milling, we can handle several kinds of surface finish, for different requirements and use

On-demand Production

From 1 to 100k+, no matter prototype production, low volume manufacturing, or mass production, our CNC milling services can support you to achieve

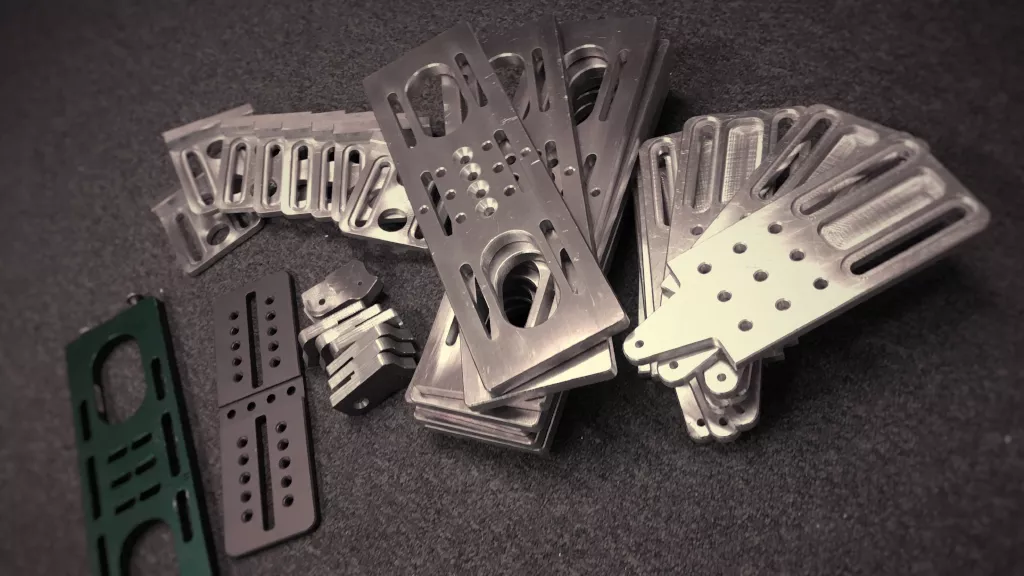

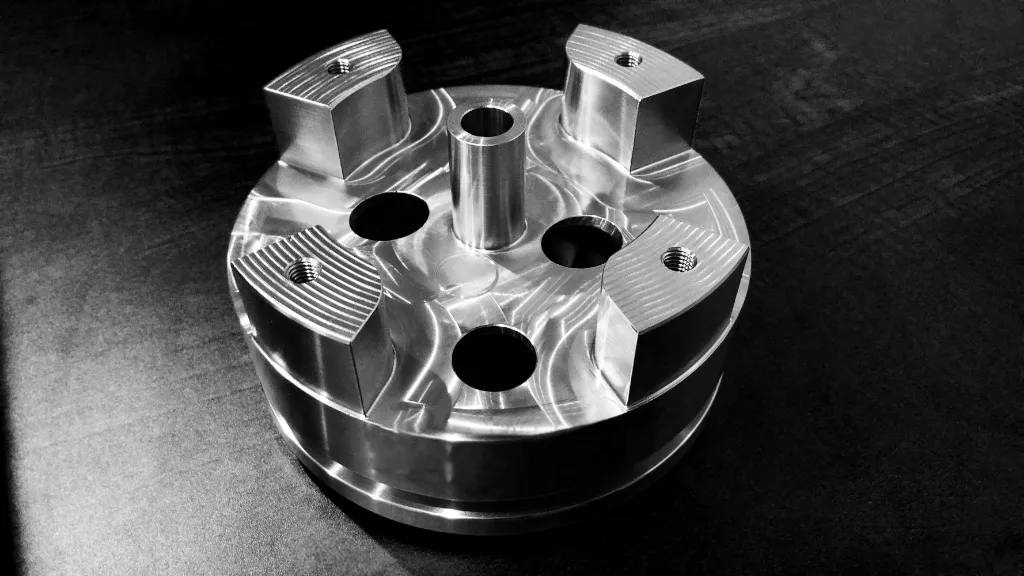

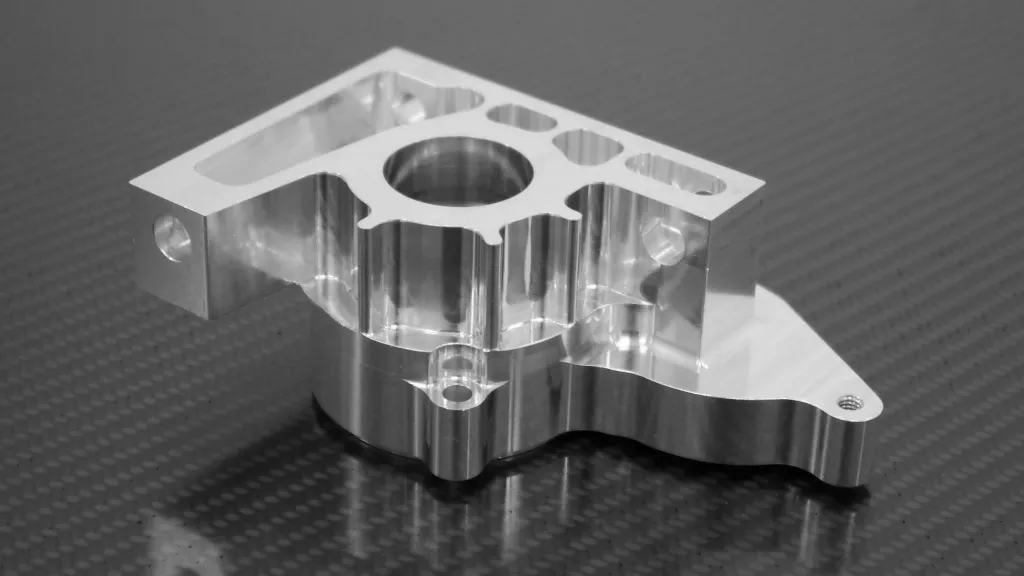

Parts Gallery

View our precision grinding and milling prototypes and parts for our valued customers.

Our Other On-Demand Manufacturing Services

CNC Machining Service

Parts In As Soon As 5-Days,Wide Variety of Materials,Finishing Options & Scalability,Tolerances down to ±.0008 in (0.020 mm)

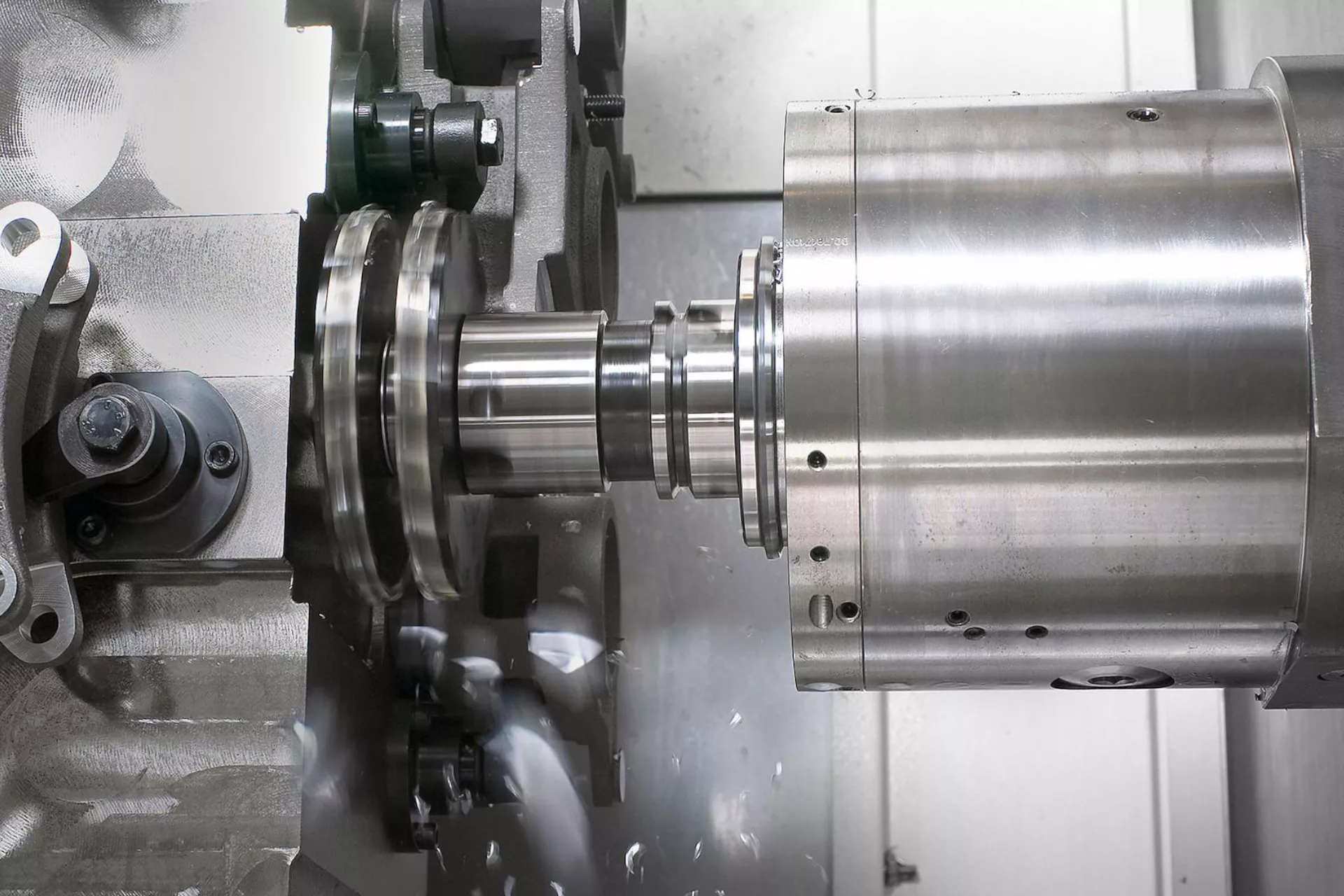

CNC Turning Service

Tolerances down to ±.004 in (0.010 mm),Over 100 CNC Turning Centers available for your projects.Multi-axis mill turns and combined machining capacities.

Rapid Prototyping Services

Choose from CNC machining and sheet metal, get free interactive designs for manufacturing feedback on every quote, and master physical prototypes in days to quickly revise designs during development.

Low-Volume Manufacturing Service

Anpllo provides a one-stop service for small-batch production of CNC machining, milling, turning, sheet metal processing, etc.

Quality Assurance

- ISO9001 certified Manufacturing Partners on request

- Inspection report included in every order. Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Strict NDA agreements with all Manufacturing Partners

- Manufacturing Partner performance tracking on lead time and quality

Industrial Applications

CNC milling parts have seen significant use in a variety of industries. With our advanced facilities and refined CNC milling technologies, we can rapidly create precision, and quality CNC milled parts.

Frequently Asked Questions

CNC milling is just one of the CNC machining processes available. Milling is a particular form of precision CNC machining. Milling uses a cutter that removes material by moving into the workpiece at an angle. The movement of the cutter is controlled by computer instructions, allowing for extreme precision and repeatability.

Besides CNC turning, CNC milling is one of the most popular custom CNC machining processes. CNC milling services are used for the majority of machined parts because it can handle a wide variety of irregular geometries. It is also an efficient means of mass production once the setup is complete.

Anpllo’s facilities contain high-end 3-axis, 4-axis, and 5-axis CNC machining centers, including models from Haas and JingDiao.

Yes. We can use a CNC machine to mill details, features, and text onto parts made using other processes like casting and 3D printing.

We accept 3D CAD files in STL, STP, STEP, OBJ IGS or IGES format and 2D drawings(jpg, png, gif, bmp, pdf) with dimensional details and specific manufacturing requirements.

We respond within 2 hours after your request. Princing quote will be send within 8 hours. If the quote is delayed, we will notify you as soon as possible.

Yes, master models are used to create silicone molds for vacuum casting and can be made from any rigid solid that can withstand heat up to 100 °C. Models used for CNC machining will be 3D scanned to create a CAD/CAM program for production.

Quality parts less than 1000pcs can be made in as fast as one week if you provide complete 2D and 3D CAD models. More complex parts requiring other special features will take longer. As for shipping, most of our shipments are via air freight, which can take 5-7 days from China to Europe or North America.

We respect your intellectual property. None of your information, images, files or likenesses will be shared with any third party, and it will not be used for any advertising, marketing, or promotional use without your explicit written authorization. If you would like to sign NDA agreement, please contact our team for support.

We follow the ISO/IATF standard and guarantee that we will rework the products or refund them if there are any quality problems. The full-dimensional report, material certification, or first article inspection are provided on request before order placement.

Resources

Analysis of NC milling process of typical disc sleeve parts

Analysis of NC milling process of typical disc sleeve parts The CNC milling of typical...

Read MoreProcessing Methods and Strategies of CNC Milling

Processing Methods and Strategies of CNC Milling The milling machine can process various planes (horizontal...

Read MoreOverview of CNC Machining of Nylon Materials

Overview of CNC Machining of Nylon Materials In CNC machining, nylon is a versatile and...

Read More

Contact US Online

For businesses Of All Sizes

Get in touch with our team to access these services:

- Add Anpllo as a vendor

- ISO 9001, material certifications, test reports and full dimensional reports

- Non-disclosure agreements

- Sample verification program (learn more)

- Dedicated account manager

or email us at [email protected]

Contact US Online

We Make Your Custom Products Better And Faster

Anpllo could help you with all the important and complex work of custom product prototyping and manufacturing, from initial designs to low-volume production, post-processing, logistics, and more. Anpllo is dedicated to speeding up your prototyping and manufacturing processes and reducing costs. Whether it’s a one-off prototype made or a batch production of thousands, Anpllo is here to help.