CNC machining of electric scooter aluminum frame CNC machined aluminum frames for electric scooters have...

Read MoreCNC Machining Services

Anpllocnc provides you with a reliable one-stop CNC machining service, which provides rapid prototyping/end-use part production in a variety of materials, and related machining services to small, medium, and large-sized parts.

- High Precision: Standard dimensional tolerance of ±0.005mm(0.0002in)

- Various CNC machines: 3-axis, 4-axis, and 5-axis CNC machines

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc

- Get your products and parts ready in as fast as 24 hours

- Get your products and parts ready in as fast as 24 hours

- Certifications: ISO9001:2008, TS16949

Our Service

Anpllocnc is a contract manufacturer that specializes in rapid prototyping using CNC machining, providing high-speed, high-precision and powerful CNC manufacturing services and products to customers around the world.

By combining precision CNC machining, engineering expertise, innovative CNC programming production technology and a wide range of CNC machinery and equipment, our high-speed CNC machining services and precision milling equipment are fully equipped for all prototypes, production molds and molds. No matter how complex or demanding your tool design is.

Our advanced CNC machining shop has prototype CNC machining centers, milling machines, lathes, and vertical, horizontal and 5-axis machine tools. These machines enable us to complete the turnaround of tools and machine components quickly and accurately. Strong team strength and complete equipment can quickly and efficiently bring your products from the design stage to market.

Our shop can provide high-volume and low-volume production capabilities. Low-volume CNC machining can quickly produce CNC prototypes and proof-of-concept parts. The CNC machining service for low-volume production has a short lead time. This is especially beneficial for time-sensitive industries.

CNC prototyping services are essential for product development. Small batch production enables designers and engineers to quickly test and improve their designs. With all aspects of production under one roof, every department and team can collaborate seamlessly.

When demand surges, our CNC manufacturing facility can scale up production. Can shift to larger production volumes when necessary.

Service Type

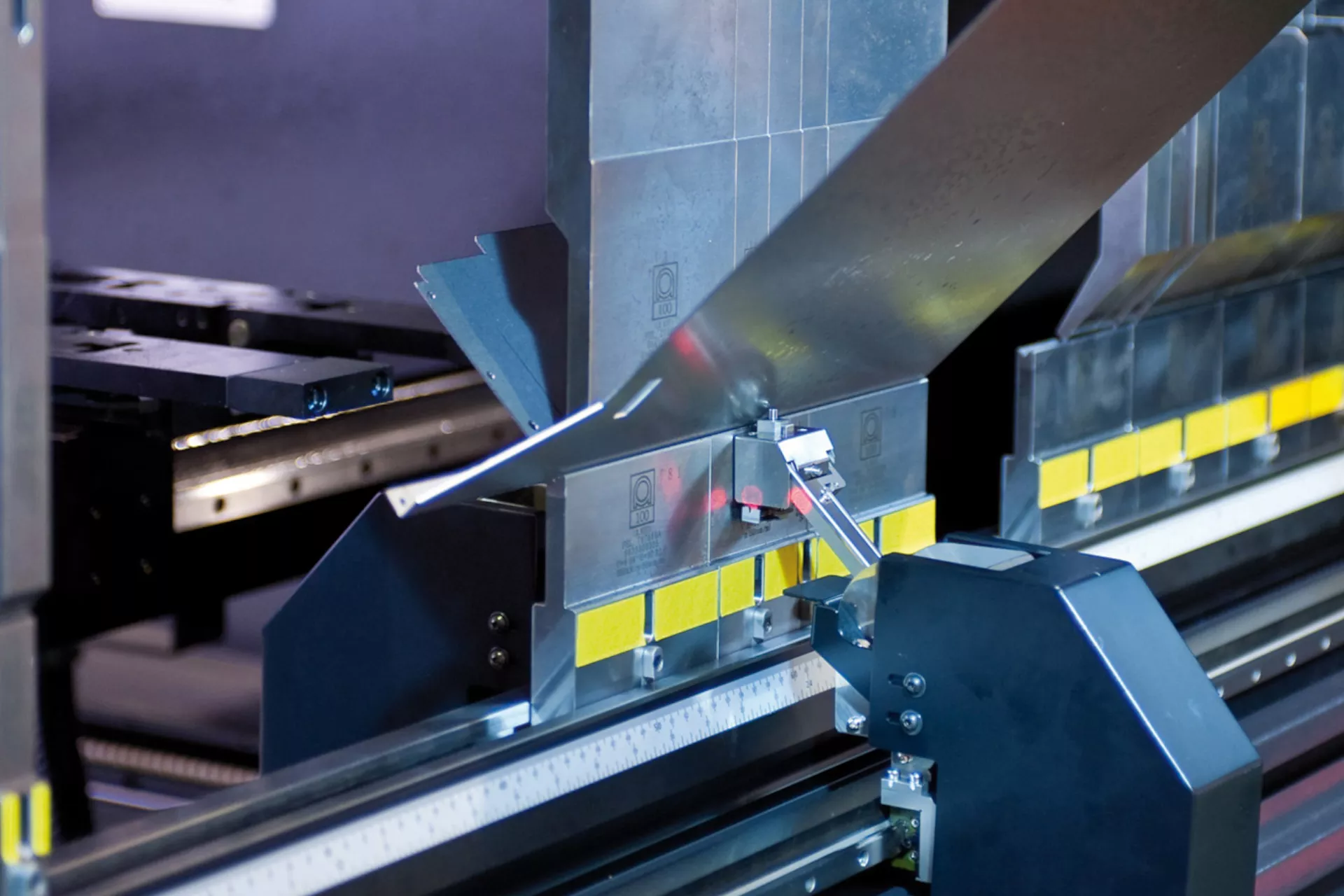

We operate almost every kind of CNC mill and turning center, and pride ourselves on being able to machine whatever you need, from simple, ‘as-machined’ workholdings to complex, organic geometries with tight tolerances. On request, we can also produce parts with EDM and grinders. Build envelopes, minimum feature sizes and design guidelines vary for milling and turning.

CNC Milling

CNC milling shapes out of a metal or plastic material blank that is usually flat, holding dimensions to tolerances as tight as 0.002”. CNC mills consist of a multi-axis system (three, four, or five axes, depending on the part complexity).

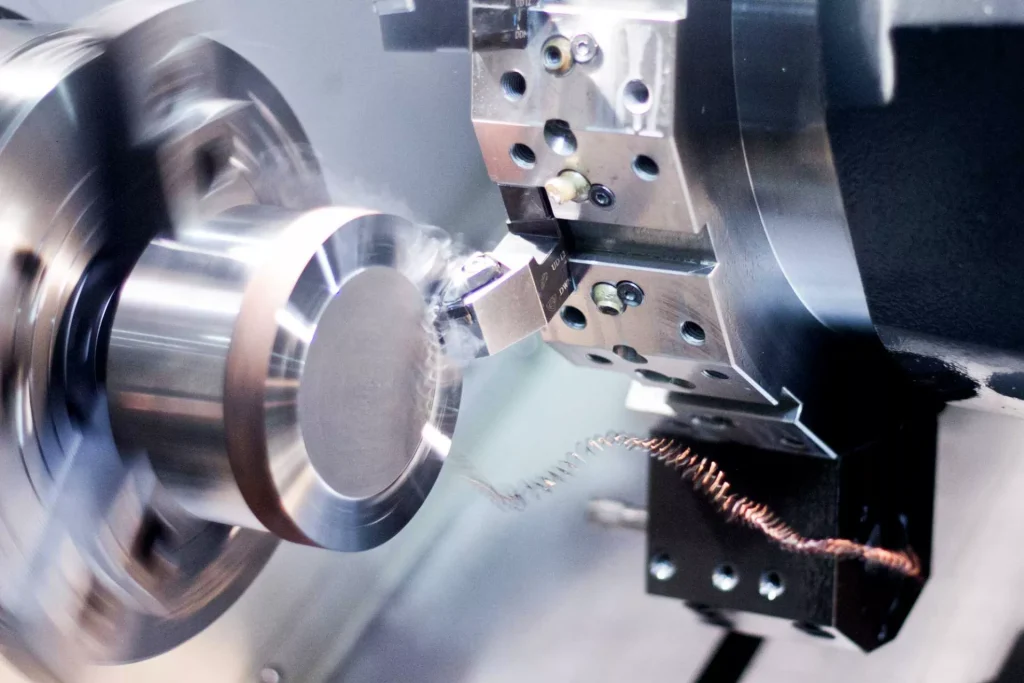

CNC Turning

CNC turning shears materials from the ouside of a rod at incredible speeds using a spinning tool. we apply 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision that consistantly meet customers’ expectations.

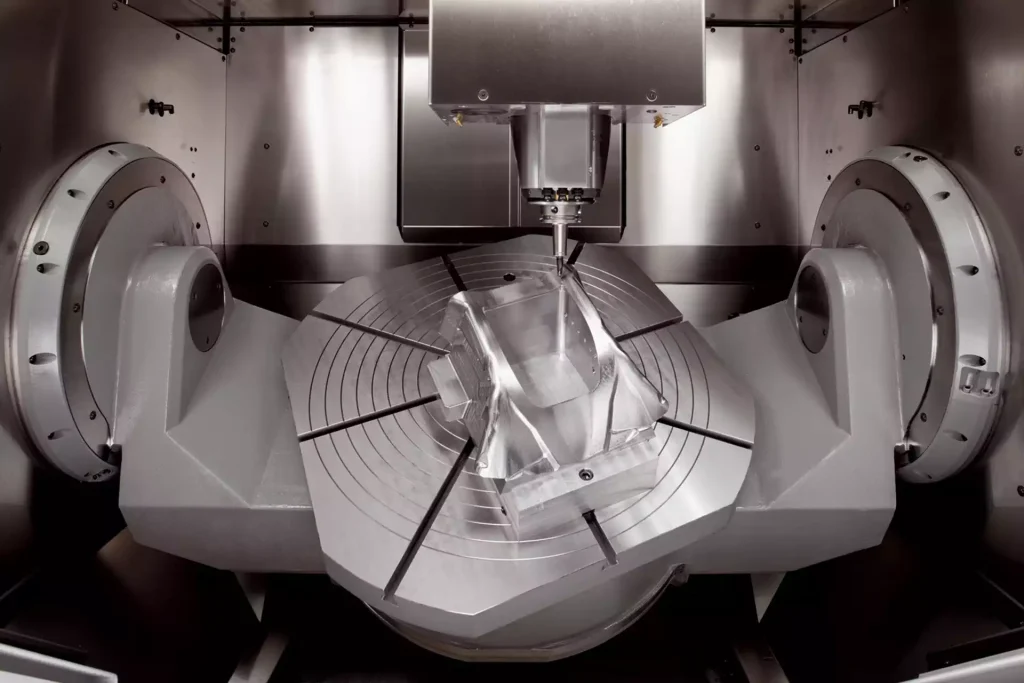

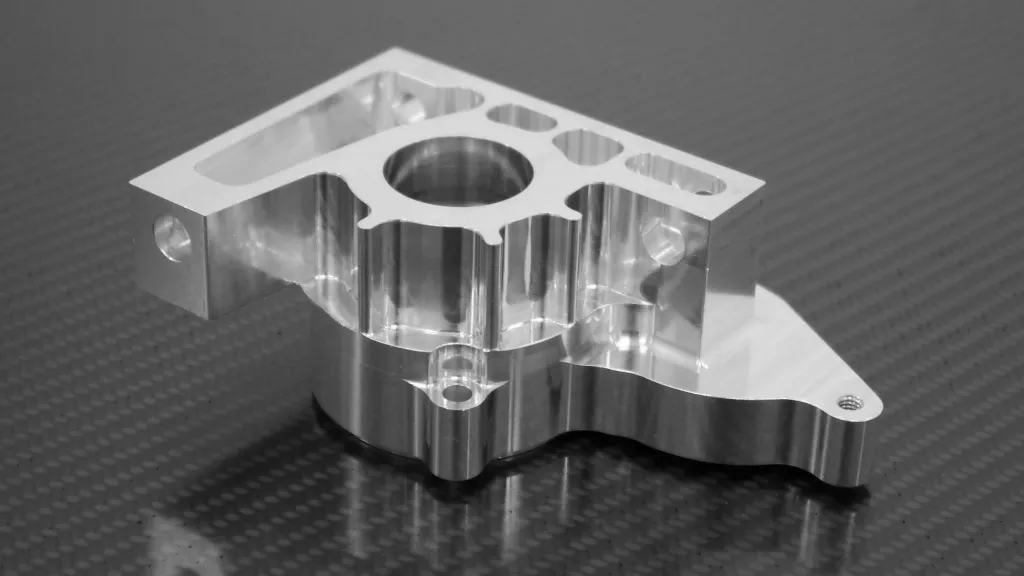

5 Axis CNC Machining

High-precision, accuracy, intricate machined parts with extremely complex geometries with our 5 axis CNC machining services. for Aerospace, Defense, Robotics, Research & Development, Medical and much more.

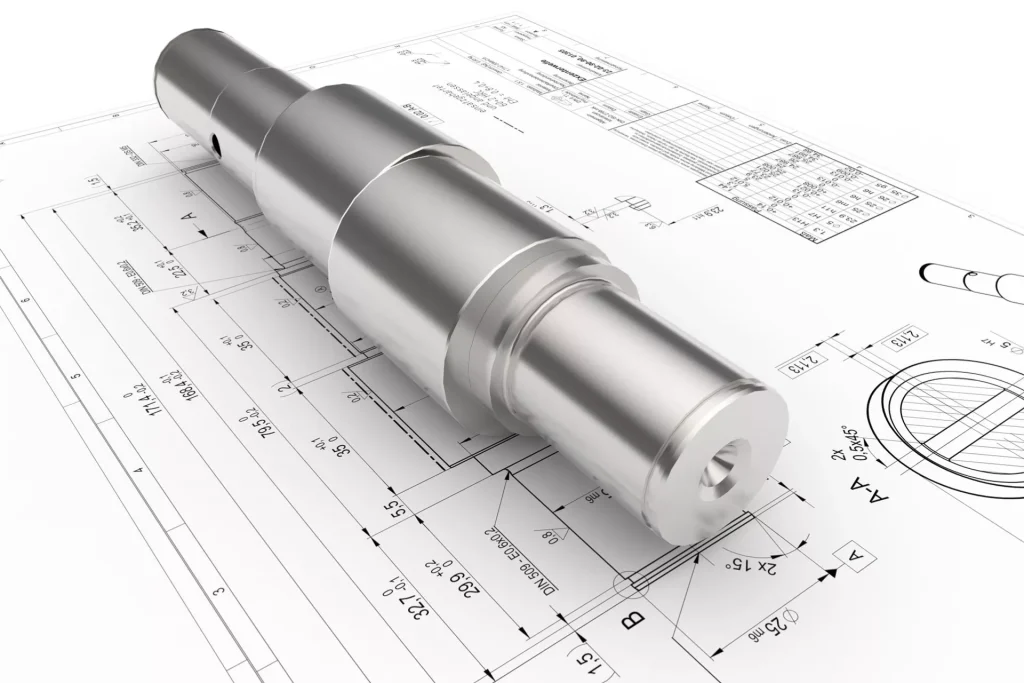

Rapid Prototyping

With advanced equipment and rich experience, we are able to translate your design and invention blueprints into manufactured prototypes in as little as 3 days and saving at least 30% in costs.

Capabilities

We understand the individual needs and requirements of our customers. Therefore, we ensure that our services are enough to provide excellent and top-tier products that our customers can rely on.So if you have any concerns or questions about CNC machining, contact us today. You can also request a quote, and we can find the best option for your project.

- Boring

- Countersinking

- Counterboring

- Drilling

- High Speed Machining

- Facing

- MillingMill-Turn

- Profiling

- Saw Cutting

- Surfacing

- Tapping

- Threading

- Turning

- Bridgeport Mills

- CNC 9-Axis Mill/Turn Centers

- CNC Horizontal Milling Centers

- (with multiple pallets)

- CNC Lathes (with live tooling)

- CNC Vertical Milling Centers

- Wire EDM Machines

- 3

- 4

- 5

- 9 (Turning & Milling Center)

- Live Tooling

- In-House Fixturing & Tooling

60″ X 25″ X 27″

Work Envelope varies by machine

- 0.002″ True Position Geometric Tolerance

- ±0.001″ Typical Hole Tolerance

- Tighter Tolerances Held According to Specifications

- Acrylic

- Aluminum (All Alloys)

- Brass

- Bronze

- Delrin

- Copper

- G10

- Lexan

- Nickel Alloys Nylon

- Phenolic

- Plastics (Various)

- Stainless Steel (2B, #3 & #8)

- Steel (CRS, HRPO & HRS)

- Titanium

- Tool Steel

- Ultem

- Angle

- Bar Stock

- Castings

- Extrusions

- Pipe

- Plate

- Tubing

- Sheet

Structural Shapes

- AS9100 Revision C Certified (#12912)

- Conflict Materials Compliant

- DFAR Compliant

- ISO 9001:2008 Certified (#12912)

- ITAR Registered (M23878)

- Reach Compliant

- RoHs Compliant

- SVHC Compliant

- Air Gaging

- Carbide Ring Gages

- CMM Equipment

- Deltronic Pins

- Digital Height Gages

- Digital Microscope

- Digital Micrometers & Calipers

- Hardness Testers

- Master Gauge Blocks

- Optical Comparators

- Virtek (Laser Scanner)

- Deburring

- Glass Bead Blasting

- Graining (Brushed Finish)

- Polishing

- Sand Blasting

- Vibratory Tumbling

- Bright Dip

- Standard (Multiple Colors)

- Hard Coat

- Barrel Plating

- Black Chrome

- Black Oxide

- Bright Nickel

- Brush Nickel

- Cadmium

- Chromate (Clear or Yellow)(Also known as Iridite or Chem Film)

- Chrome

- Copper

- Etching

- Electroless Nickel

- Electropolish

- Gold

- Hard Chrome

- Passivation (Nitric of Citric)

- Phosphate (Pretreat)

- Rhodium

- Silver

- Tin

- Zinc (Clear, Yellow or Black)

- Hexavalent

- Trivalent (RoHs Compliant)

- Zinc Cobalt

- Plating Certified to AS9100, ISO, ITAR & NADCAP

- Dielectric Paint

- E-coating

- Powder Coating

- PTFE

- Wet Paint

- Assembly

- Centerless Grinding

- Engraving

- Heat Treating

- Ink Fill

- Kitting

- OD Grinding

- Silk Screening

- Wire EDM

- Blanket Orders Accepted

- High Volume

- Low Volume

- Prototypes

- Over 5,000 Parts Typical

- 1-2 Week Expedited Service Available

- 4-6 Weeks Typical

- Specific Lead Time Quoted on a Job by Job Basis

- Autodesk Inventor (Preferred)

- Any .STP File

- CADKEY

- CATIA

- NX (Unigraphics)

- Parasolid

- Pro/E

- Solid Edge

- SolidWorks (Preferred)

Tolerances

We can be your exclusive partner for creating precision machined prototypes and batch parts, we guarantee that all parts will be manufactured according to your specifications, as long as you specify the requirements on the drawings, we can also achieve special tolerances.

| Abilities | CNC Milling | CNC Turning |

| Maximum Part Size | 1300*800*300mm | 300*500mm |

| Minimum Part Size | 1*1mm | 1*1mm |

| Minimum Feature Size | 0.3mm | 0.3mm |

| Standard Tolerances | 0.005mm | 0.005mm |

| Linear Dimension | 0.005mm | 0.005mm |

| Hole Diameters (Not Reamed) | 0.005mm | 0.005mm |

| Shaft Diameters | 0.005mm | 0.005mm |

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter | Diameter: Φ 1.5-5 mm, depth: 3×diameter |

| Laser Etching | Minimum width of 0.5 mm, depth of 0.1 mm | use laser marking to create standard text for CNC turned parts |

| Lead Time | 3 Business Days | 3 Business Days |

| Maximum CNC parts size varies by material.Contact our team if you need further information.Click Here Mail to Anpllocnc | ||

In Precision Parts Manufacturing

You Deserve A Fast, Hassle-Free CNC Machining Experience

Your manufacturing partner for CNC manufacturing, prototyping and production of custom parts. Your project is unique, and we deliver the service it demands.Get your design quoted and assessed by our CNC team. We’re here to help.

What is CNC Machining?

CNC machining is a subtractive manufacturing process that typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries, such as large CNC machining, machining of parts and prototypes for telecommunications, CNC machining aerospace parts, CNC machining motorcycle parts and automotive parts, which require tighter tolerances than other industries.

At Anpllo CNC, our precision CNC machining services make complex finished parts and components, as well as tools for plastic injection molding or pressure die casting. CNC machine cutting tools come in many specialized types to perform all kinds of operations on the raw stock. However, CNC mills are the most common and versatile multi-axis machines that we use.

Prototype Parts

CNC machining is versatile for producing prototype parts in engineering plastics, metals, and alloys materials, such as ABS, HDPE, Aluminum, Stainless Steel, Mild Steel, Titanium and others . it produces in quick and cost-effective ways, in terms of controlling geometric tolerance, CNC machining is more accurate compared to other processes, like 3D printing and Vacuum casting, thus, it can be a great choice for functional prototypes and its benefit for product development.

Generally speaking, we will support CNC machined parts by other processes if move into batch production, like series CNC machine invested, or casting options. so currently CNC machining is used for low-volume manufacturing, and high-volume can be handled by other production tool ways. and no obstacles for meeting customer demand.

Advantages

CNC milling and turning are highly accurate and repeatable processes. Tight tolerances between +/-0.001″ – 0.005″ can be achieved, depending on specifications. Machines can be programmed to reliably run for 24 hours, 7 days a week if necessary, so CNC milling is a good way of getting parts produced on demand.

Using standard tooling, a CNC machining service is particularly valuable for creating one-off parts, custom CNC parts, i.e., for replacing legacy components or delivering a specialized upgrade to a customer. It is also conceivable to scale single-part production to runs exceeding 10,000 units. Depending on the unit number, size, and complexity, the turnaround for CNC machined parts can be as short as one day. With shipping and delivery, deadlines can be met within a week.

Another primary advantage of CNC technology is its achievable mechanical properties. By cutting away from bulk material, rather than thermally transforming it as in injection-molding or additive manufacturing, all desirable mechanical properties of the metal or plastic of choice are retained. More than 50 industrial-grade metals, alloys, and plastics can be machined using CNC milling and turning. This selection includes aluminum, brass, bronze, titanium, stainless steel, PEEK, ABS, and zinc. The only material requirement for CNC machining is that the part has an adequate hardness to be fixtured and cut.

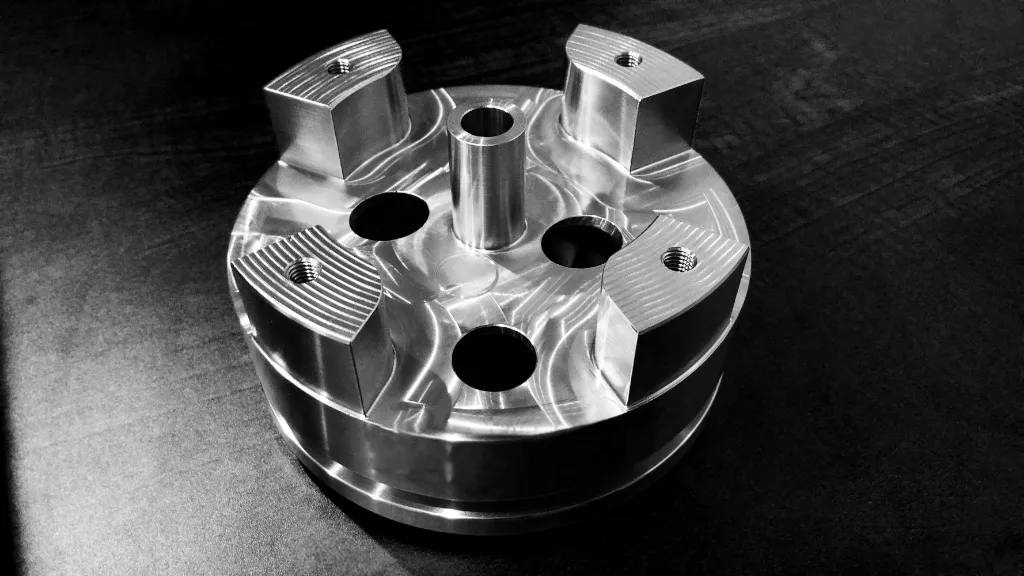

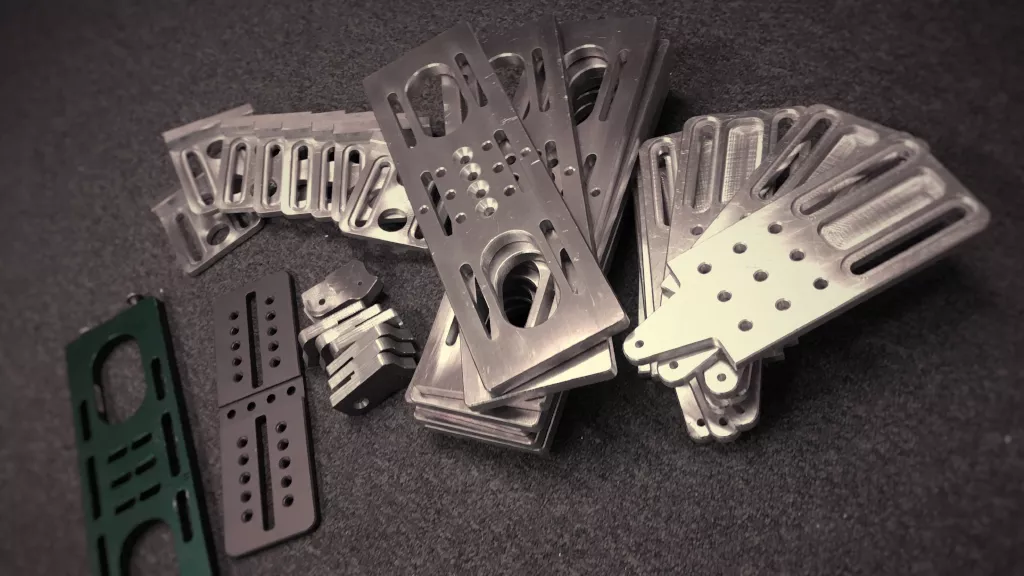

Parts Gallery

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

Various Industrial Applications

Anpllocnc works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Our Quality Promise

- Inspection reports included with every order

- All CNC-machined parts inspected using hand metrology, CMM or laser scanners

- All manufacturing partners are highly vetted and managed

- ISO 9001 certified, AS 9100 & ISO 13485 compliant

- Quality guaranteed. If a part is not made to spec, we’ll make it right.

- Material certifications available

Why Choose US

Write a request for a quote email, send your design files, and get an instant CNC quote. Our engineers analyze your part geometry and provide real-time, competitive pricing with comprehensive DFM feedback.

We strictly implement a quality management system to ensure the expected product quality consistently. Full inspections also ensure you receive precision machined parts without unwanted defects.

We have a digital CNC machining services platform that provides a faster ordering process; we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

No matter where you are, you can get our 24/7 engineering support all year. Our experienced engineer can provide the most appropriate solution to your part design, material selection, surface finishing options, and lead time.

The Anpllo Standard - Consistent Quality, Every Time

Anpllo takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Our in-house quality control team dimensionally and visually inspects each order to ensure it meets the Anpllo Standard. If you’re unsatisfied with your order, we’ll remake your parts as fast as possible, free of charge, or refund you – whichever you prefer.

Threads And Tolerances

Cosmetic Standards

General Finishing

Non Standard Features

Inspection Standards

Quality Documentation

From Prototype To Production

Mid Stage Prototypes

Prototype CNC machining is an ideal process for mid-stage functional prototypes. Anpllo can help you accelerate development cycles with rapid prototyping by providing instant online quotes, intelligent DFM feedback, and quick lead times.

- Finishing, masking & hardware installation

- CNC Milling, CNC turning, gear hobbing, EDM

- Tolerances as tight as +/- 0.0002″

Production Parts

Custom CNC machining is often leveraged for end-use production grade parts. Anpllo’s global manufacturing network is optimized for production machining, with volumes up to 1M units.

- Inspections using CMM or laser scanners

- Material certification available

- ISO 9001 certified, AS 9100 / ISO 13485 compliant

Production Tooling

Online CNC machining services are ideal for manufacturing components needed for production, including fixtures, jigs, gauges, molds, dies, cutting equipment, and patterns.

- Economical pricing options

- 2D drawings accepted

Design Guidelines

| Feature | Description |

|---|---|

Internal corner fillets | Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii. |

Floor fillets | Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. |

Undercuts | Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool. |

Tapped/threaded hole depth | Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads. |

Complexity | Keep the number of small cuts to a minimum to reduce CNC machining costs; only design in the necessary features to balance function with aesthetic. |

To see more CNC machining resources, view our CNC Machining Design Guide.

Our Other Manufacturing Services

Low-Volume Manufacturing

Sheet Metal Fabrication Services

Frequently Asked Questions

ANPLLO can accommodate the prototyping and production of large machined parts, plastic or metal. Our maximum CNC machining build envelope is 2000 mm x 1500 mm x 300 mm — suitable even for large-scale parts such as furniture and architectural components.

The primary advantages of CNC machining include rapid prototyping and the ability to produce full-scale production parts quickly. It offers a high level of precision and accuracy in manufacturing parts and allows for tight tolerance machining for CNC parts of all sizes. It also offers maximum flexibility across volume, pricing, lead times, and the range of materials and finishes being used.

The two primary CNC machining processes are CNC turning and CNC milling. Other machining processes include drilling, gear hobbing and electrical discharge machining, among others.

We can serve more than 10000 pcs of different prototypes monthly, no matter the part with simple or complex design. We own 120 CNC machines and have more than 100 experienced technical experts.

Industries that use CNC machining include aerospace, automotive parts manufacturing, medical machine manufacturing, transportation, defense, and marine industries, along with oil and gas industries and electronics. CNC machining has allowed these industries to become more efficient at mass-producing custom CNC parts.

The cost of your CNC machining projects is not fixed as it depends on the characteristics of your project such as the design, and tolerances. Machining times of the material to be used in the project also contribute to this pricing. For example, if you’re making a part that has a combined machining and material cost of $2 and a setup cost of $200, one part will cost $202. However, if you make 200 parts, each would cost $3!

The standard machining tolerance is ± 0.005″ or 0.13mm. Tolerances are the allowable range for a dimension. If a CNC machining tool has a tolerance of ± 0.01 mm this means that the machining tool can have a deviation of 0.01 mm in every cut. With a drawing, ANPLLO’s CNC machining service can produce CNC parts with tolerance as low as ± 0.0002 in. Without a drawing, all CNC parts are produced to our ISO 2768 medium standard. We can also machine to tighter tolerances, ±0.025mm or ±0.001″, with an attached engineering drawing calling out critical features.

Resources

What’s behind the low costs of CNC aluminum parts from China?

What’s behind the low costs of CNC aluminum parts from China? Today, Chinese factories are...

Read MoreWhy do Chinese factories offer such low-priced CNC-machined anodized aluminum parts?

Why do Chinese factories offer such low-priced CNC-machined anodized aluminum parts? Introduction:The process of CNC...

Read MoreCustomized Parts Service: CNC Milling and Turning Machine Shop in China

Customized Parts Service: CNC Milling and Turning Machine Shop in China Introduction: Industries need customized...

Read More

Contact Anpllocnc

Machined Parts on Your Schedule

Our lead time options lend you flexibility. Need machined parts lightning fast? Select Expedite at checkout. Not in a rush? Choose Economy to save on cost. For reliable delivery on-time, select Standard. Your parts when you need them.