Stereolithography (SLA) 3D Printing Service

At Anpllocnc, we are proud to work with over 300 experienced and rigorously vetted manufacturers who have a proven track record of manufacturing high-quality, high-precision SLA 3D printed parts for customers around the world. With the expertise of our partners, the attention to detail of our engineers, and our entire team’s commitment to exceptional quality assurance at every stage, you can rest assured that with Anpllocnc you are getting the best SLA 3D Printed Parts – No. Once, every time.

Our SLA 3D printing service

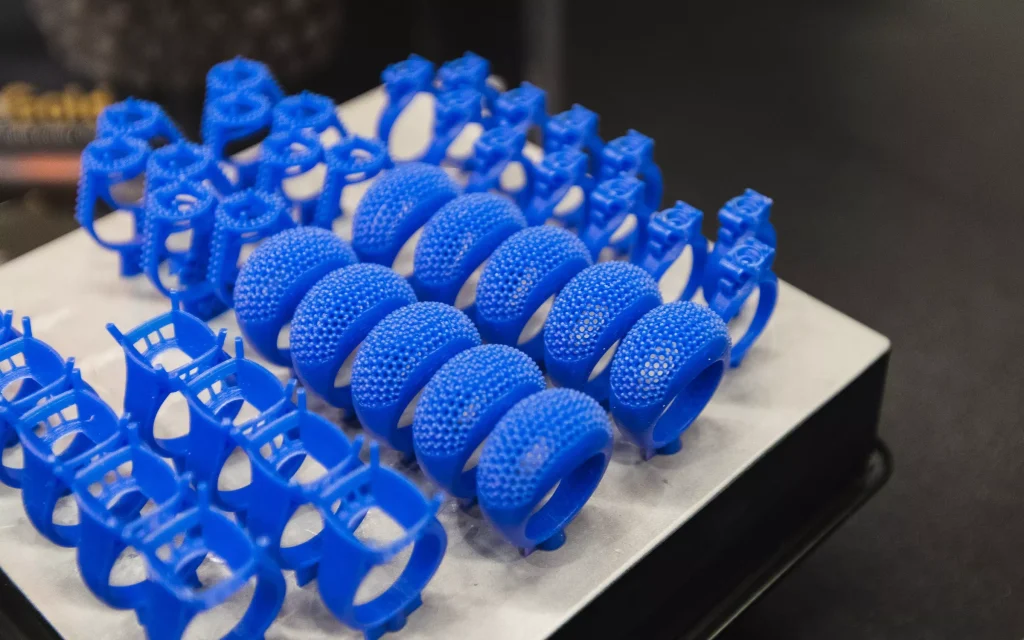

At Anpllocnc, our SLA 3D printing service in China serves a wide pool of clients. As with most 3D printing services, prototyping is among the top uses for numerous industries. Whether the prototype end-use is for marketing campaigns, or as the first step in creating technical molds or casts, our accurate and detailed production provides a fast and useful solution. Other common uses of stereolithography printing include small-scale manufacturing, and medical modeling or prosthetic production. In addition, SLA 3D printing services are a popular choice among engineers in New York for its fine detail, and ability to create small features as well as extraordinarily large components.

Our in-house production capabilities for SLA rapid printing are vast. If you have questions or need help finding the right printing method for your project, Please contact us for more information.

Custom SLA 3D resin printing services

Anpllocnc offers custom SLA 3D printing services that cater to clients seeking high-quality, intricate, and detailed parts. Our state-of-the-art custom resin printing technology enables us to produce accurate prints with exceptional precision, making it a great choice for creating appearance models, product prototypes, experiential marketing material, and other intricate parts. Our team of experienced designers works closely with clients to ensure that every aspect of their project is tailored to meet their specific needs, from the initial consultation to the final product. Our custom SLA 3D printing services provide clients with the flexibility to experiment with different designs and materials, ultimately leading to a superior final product. With our commitment to quality and attention to detail, Anpllocnc is the ideal partner for clients who demand nothing less than the very best in SLA 3D printing services.Get a quote now using our online quote platform.

SLA Capabilities

| Maximum Printing Size | 1650*760*580mm |

| Lead Time | 48 hours or 72 hours |

| Tolerance | ± 200μm or 0.2%mm |

| Minimum Layer Thickness | 0.6 mm |

SLA Design Guide

| Tolerances | +/- 0.2% (with a lower limit of +/-0.2mm) | |||

| Supported Walls | Min 0.4mm thick | |||

| Unsupported Walls | Min 0.6mm thick | |||

| Overhangs | Length < 1mm: Min. 19° level | |||

| Connections | 0.2mm assembly connections 0.2mm snug fits | |||

| Engraving | Min 0.4mm wide & 0.4mm thick | |||

| Embossed Details | Min 0.1mm height | |||

| Holes | Min 0.5mm diameter | |||

Design & Production Considerations

Diverse engineering grade material library with options available to simulate almost all types of polymers

Most parts require printing on a very thin support structure that can leave small “pits” when removed. These pits are typically removed during standard post processing, but it is preferred to orient parts with cosmetic surfaces away from supports

Although the printer is capable of generating extremely high accuracy, the inherent properties of many materials make some parts susceptible to distortion or warping during the final curing process.

The parts are printed in a resin vat, which can trap liquid resin if there is any hollow geometry without a hole to allow the resin to drain out during post processing

Available materials for SLA

SOMOS Resin

Somos resin is an fast printing material that produces high quality parts with great details. The final finishing is outstanding and almost achieve the industry injection plastic quality. It is perfect for building end-use parts or prototypes for functional testing applications

Standard Resin

Fine details and the basic resin for modeling and prototyping. Sharp edges and smooth finish. Great for small and complex projects. Comes in multiple colors.

ABS

ABS resins produce high stiffness, high resolution prints with a smooth injection molding-like finish. Their low-cost makes them ideal for prototyping applications. The color of the resin affects its properties. For example, grey resin is better suited for parts with fine details and white resin for parts that require a very smooth surface.

Tough resin

Tough Resin simulates the feel and many of the important mechanical properties of ABS plastic. Consider using this material for works-like prototypes and assemblies, including designs with snap fit joints and living hinges. For further finishing, Tough resin can also be machined once printed.

Poly1500

Poly1500 is a durable, resilient material that offers high surface quality and dimensional accuracy. With properties similar to polypropylene, it is ideal for functional prototypes.

Castable Resin

A 20% wax-filled material for reliable casting with zero ash content and clean burnout.

ProtoGen White

ProtoGen White’s resilience, surface quality, and thermal properties make it suitable for general-purpose applications such as RTV molding patterns, highly detailed parts, and durable concept models.

TuskXC2700W

Designed to simulate ABS, TuskXC2700W is a strong material with a rapid lead time. It is ideal for water-resistant and functional prototypes. Also available in clear.

Tusk Somos SolidGrey3000

Exclusive to Materialise, Tusk Somos SolidGrey3000 combines very high stiffness and impact strength. It is ideal for functional prototypes, durable concept models, robust scale models, as well as end-use parts.

Available Finishes for SLA Parts

| Matte (Standard) | Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper, then media blasted for a uniform matte finish. |

| Natural | Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces. |

| Strip and Ship | Supported areas may show small grid-like dots or surface blemishes as a result of support removal. |

| Quick Clear | Available for Accura ClearVue. Only supported surfaces are sanded. Parts will still have visible layering. High gloss clear coat is applied to enhance natural clarity. |

| Custom | Anpllocnc provides additional SLA finishing options, including but not limited to sanding, polishing, painting, post thermal processing, and plating to meet your needs. |

Need High-Quality Additive Parts Fast? Stereolithography (SLA) Can Help

If you’re looking for a fast, low-cost way to produce presentation models or test the fit and finish of prototype parts, stereolithography (SLA) is an ideal solution.

Anpllocnc provides you the best online 3D Printing Services for your resin parts. Thanks to our expertise in Stereolithography technology, you can choose between several options, instantly receive a quote, and let us handle the manufacturing in our ISO 9001 certified factory.

Start using Stereolithography today by uploading a 3D file.

What Is Stereolithography (SLA)

Stereolithography, or SLA 3D printing technology, is a popular additive manufacturing technique and sought-after service in China and across the globe. It works by making use of light-reactive thermoset materials called “resin.” The technology uses a light source (a laser or projector) to cure and harden the photosensitive liquid resin into the desired 3D shape.

Patented in the 1980s, the technology is the first 3D printing technology ever developed. Until today, the veteran 3D printing technique remains to be one of the three most common 3D printing technologies along with FDM and SLS.

SLA 3D prints each layer from top to bottom, and the build platform lifts the model upwards, out of the resin bath.

How Sterolithography (SLA) Works

Stereolithography (Monikers: Vat photopolymerization, photocuring, SLA, SL) relies on a precise UV laser to cure liquid resin layer by layer. Its build platform sits just below the top of the resin bath. The build platform is coated with a thin layer of liquid plastic.

A UV laser hits dynamic mirrors which direct the UV energy downwards across the build platform, curing the liquid resin in precise patterns one cross-section at a time. After each layer is cured, the build platform retracts into the bath of liquid while a recoater blade evenly distributes the resin across each new layer.

Stereolithography also requires build supports which are removed manually by hand, meaning areas that require support be accessible. Stereolithography support material is the same material as the final part.

During printing, the resin within the chamber can become trapped within the part or pool in certain part features, reabsorbing into the part and causing bloating and design distortion. Therefore, after a build is complete, excess resin is drained and supports are removed.

Unlike PolyJet, Stereolithography parts do not fully cure during the build so the parts enter a UV oven to complete curing. Expertise comes from experience, and being that Stratasys Direct has been building SLA parts almost since the industry’s birth means that we know exactly how to build and post-process SLA exactly to your needs.

The pros of SLA 3D printing

There are many reasons to consider stereolithography, including these:

- Detail: Stereolithography technology produces crisp, highly detailed results with a professional appearance due to the advanced performance of galvanometers

- Speed: Products go from drawing board to manufacture in a day rather than much longer using traditional prototyping and production methods

- Strength: The photopolymer resins bond chemically to produce stronger models, objects and prototypes

- Water-resistance: The objects produced are waterproof and can be used to produce water-tight pieces

- Material options: A variety of resins can be used to manufacture to create objects with the physical properties of hardness, density and flexibility that are desired for each project

SLA Applications

Delivering the smoothest surface finish of any additive manufacturing process, the quality of SLA parts makes this versatile technology great for:

General

• Design verification models for appearance and proof-of-concept models

• Functional prototypes and models for form and fit testing

• Wind-tunnel test models

• High clarity, transparent products and components

• Complex assemblies

• Under-the-hood components

• Mass customization

Tooling and patterns

• Investment casting patterns

• Sacrificial patterns for metal casting

• Custom assembly jigs and fixtures

• Tools, molds and dies

• Cast urethane/vacuum casting master patterns

How is SLA printing different from other 3D printing processes?

The main differences between SLA printers and other processes lie in the aggregate state of the operating materials and in the binding or curing energy source. Most 3D printers work with solid materials such as powder materials or plastic strands. The SLA printing process, on the other hand, works with liquid plastics. The binding component varies among 3D printing technologies from chemical binders to heated nozzles to lasers. Stereolithography relies on UV light to react with the photosensitive polymer resin and transfer it to the solid state.

Alternatives to SLA

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- PolyJet

contact us

Ready to get started on your SLA 3D Printing quote?

Our stereolithography 3D printing services are Ideal for form-and-fit checks, concept models, presentation models, and master patterns. SLA is used to create parts and light-duty functional prototypes in the automotive industry, medical instruments, oil and gas, and consumer products.

Get a quote now and get the best SLA manufacturing companies in the China to transform your CAD designs into elegant models, patterns and prototypes.