Manufacturing on Demand for the Aerospace Industry

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- AS 9100 certified manufacturing

- Tight tolerances & complex geometries

- Get full IP protection and quality documentation

Give your Aerospace Supply Chain a Boost with Manufacturing on Demand

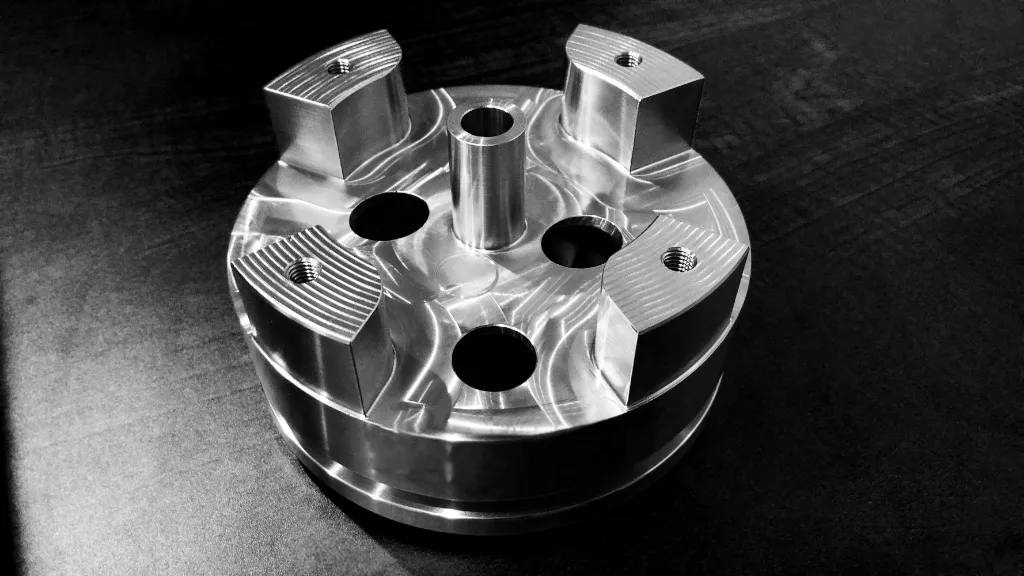

Anpllo takes immense pride in being an audited and partially certified supplier, actively contributing to the advancement and operations of the Aircraft and Aerospace industry. We are fully committed to manufacturing precision aerospace components with the utmost accuracy to meet the unique requirements of each application. Whether it’s hinges, bushings, manifolds, clamps, or other custom-made parts, we understand that aerospace equipment and aircraft demand top-notch components crafted from the finest quality metals to ensure optimal functionality and performance.

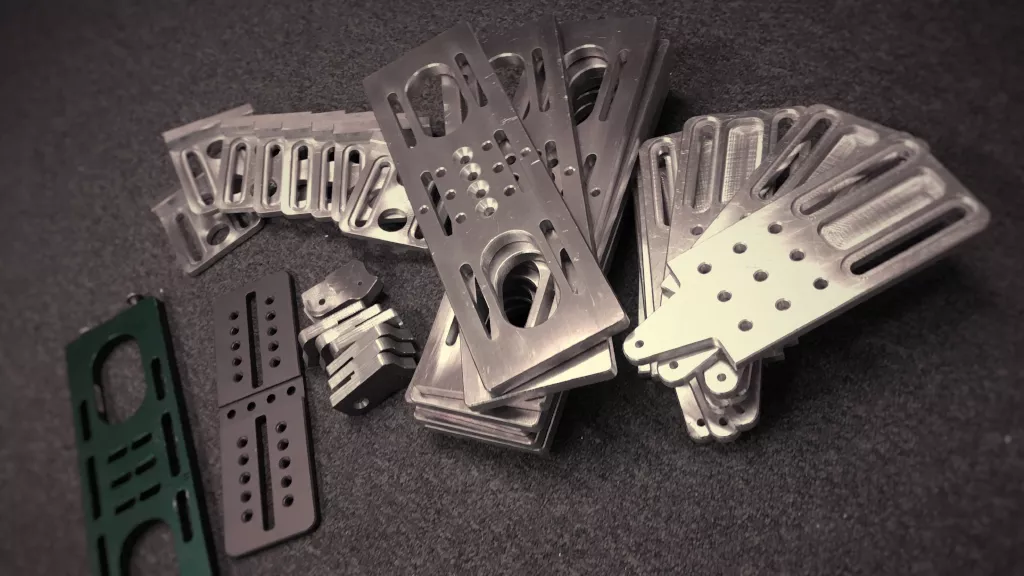

We specialize in single-part prototyping, short and medium production runs, and blanket order arrangements with scheduled releases. We offer computerized and manual milling and turning, wire EDM, waterjet cutting services and laser-cutting services.

Our CNC department utilizes CAD/CAM software to download customer drawing files or schematics. Our diverse machining capabilities allow us to produce complex components, jigs, fixtures, gauges, and modifications to existing parts.

Aerospace precision machining requires the highest-quality materials and close attention to drawing notes and manufacturing procedures. We have a certified quality management system, in accordance with AS9100 and ISO 9001:2015. All of our manufacturing, assembly, repair, and engineering services follow the highest industry standards.

While aluminum stands as the most commonly utilized material for aerospace components, our expertise extends to working with a diverse range of other materials. This includes stainless steel, nickel alloy, copper, and certain types of plastic. By leveraging our knowledge and capabilities with various materials, we offer our customers a wide selection of options to suit their specific design, performance, and durability needs.

Source custom aerospace & aviation parts

Anpllocnc is a manufacturer of high-precision aerospace parts and assemblies. As a Tier 1 supplier, we offer a competitive advantage to the aerospace industry through product design for manufacturability, state-of-the-art CNC machining services, massive machining capacity, vast managed special processes – Nadcap Accredited, on-time delivery, and unmatched customer service. We are an aerospace machine shop specializing in complex aerospace components machined from superalloys and other exotic metals. Our multi-axis machining capabilities and inspection services meet or exceed the most demanding aerospace projects’ requirements, making Anpllocnc one of the most trusted airplane parts manufacturers.

Certified for aerospace & aviation

Anpllocnc is ISO 9001 certified and our have specialized certifications.

• ISO 9001

• AS 9100

• ISO 13485

• ISO 14001

• ISO TS16949

Comprehensive quality documentation

Get validation reports to ensure the highest quality and compliance.

• CMM Inspection Report

• Full Dimensional Inspections

• Material Test Reports

• Material Certificates

• Certificates of Conformance

• First Article Inspections

Highest quality standards

We use a rigorous set of protocols and procedures to maintain quality.

• Special tooling

• Sample size inspection

• Dimensional checks with calibrated equipment

• Review of all quality documentation and industry certifications

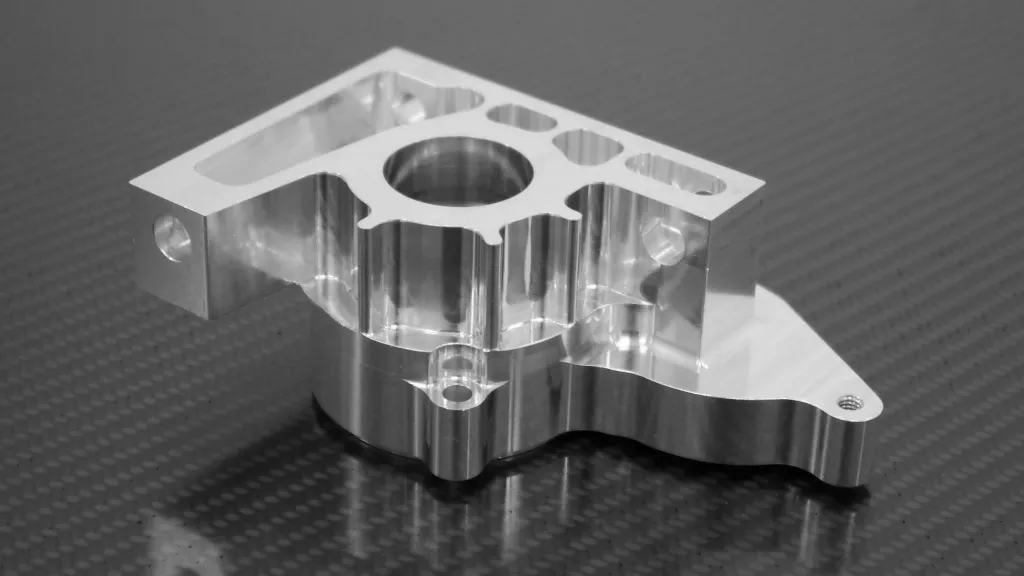

Machining capabilities for Aerospace industry components

Our ability to comply with the rigid standards of AS9100 D has allowed us to become experts in the development of the most complex airborne components.From ultra-thin wall applications to more robust high nickel components, our optimized processes and advanced techniques allow for success every time, whether as a prototype or actual component carrying precious cargo through the heavens.

- Prototyping

- Tooling

- Jigs & Fixtures

- Surrogate parts

- Drones

- UAVs

- CubeSat

- Fuel pumps

- Structural components

- Small sensors

Aerospace & aviation manufacturing capabilities

Aviation and aerospace operations require no-fail parts with tight tolerances. Each piece has to fit precisely, withstand high pressures, and be lightweight. Precision CNC machining can meet these strict quality standards and safeguard human life. Take advantage of our professional manufacturing services throughout the production cycle, from prototyping and design validation to functional testing and product launch. We deliver high-quality and precise flight-worthy components with fast turnaround and at low costs. With our quality control process, you can be sure of getting parts that meet your unique requirements.

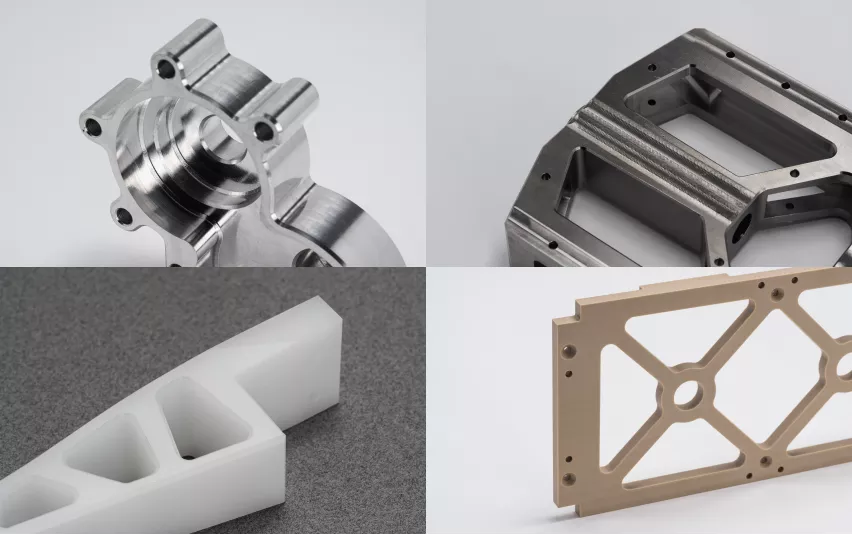

CNC machining

Milling, turning and post-processing

- Tolerances down to ±.0008 in (0.020 mm)

- Lead times from 5 business days

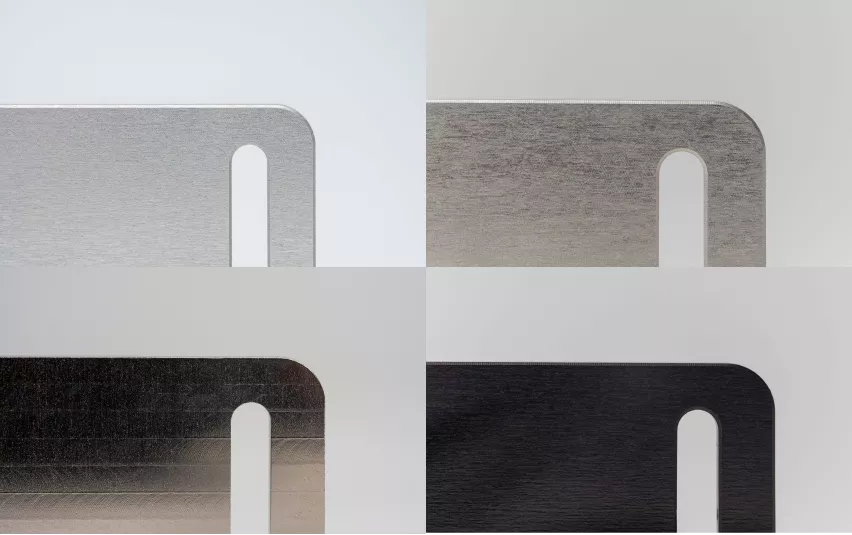

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±.004 in (0.010 mm)

- Lead times from 5 business days

Rapid Prototying

Rapid Prototying production

- Wide range of part complexities and sizes

- 1 to 1M parts

Why aerospace & aviation companies use Anpllo

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, Anpllo’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Tight Tolerance Aerospace Parts

We can machine aerospace parts with tight tolerances up to +/-0.001 inches. We implement ISO 2768-m standard tolerance for metals and ISO-2768-c for plastics. Our manufacturing capabilities can also accommodate intricate designs for custom part manufacturing.

Fast Cycle Time

With quotes within minutes and parts within days, you can reduce cycle times by up to 50% with Anpllo. A perfect combination of advanced technologies and extensive technical experience helps us deliver superior-quality aerospace parts with faster lead times.

An ever growing industry

The aerospace industry encompasses many market areas. It involves the design and manufacturing of aircraft and spacecraft, as well as missiles and other components used in the earth’s atmosphere and surrounding space. There is a constant demand for highly precise components within this industry as even the smallest imperfection can result in costly damages or danger to human life. Precision is also crucial in ensuring optimal functionality under high-altitude and high-pressure conditions.Anpllocnc to bring you the world’s most comprehensive manufacturing solution. Anpllocnc offers the industry’s fastest lead times with parts from just 1 day and ITAR compliance.

Materials & surface finishes for aerospace & aviation parts

Through our manufacturing, we provide access to strong, lightweight materials and surface finishes that can weather every application.

Aerospace & aviation materials

Select from a broad range of industrial-grade materials

Aluminum alloys: Al 2024, Al 2014, Al 7050

Titanium alloys: Grade 1, Grade 2, Grade 5

Stainless steel: SS 304/304L, SS 316/316L, 17-4PH

Inconel: Inconel 718

Plastics: Ultem 9085, PA 6 Glass Filled, PA 12, PEEK, PTFE (Teflon)

Aerospace & aviation surface finishes

Select from these finishes to protect your parts

Custom Parts for Aerospace Industry

Our metal manufacturing services for aerospace can help produce parts and components made of titanium, carbon steel, stainless steel, aluminum, and many more. We can fabricate cabinets, boxes, different kinds of covers, flat pattern parts, support, angles, and many other products featured on most aircrafts.

How Anpllo meets the custom parts needs of aerospace companies

Competitive pricing, IP protection, and DFM guidance

Anpllo is the easiest way to get competitive prices and can be used to compare items on order quantities, lead times, materials, tolerances, secondary processes, and more. All final pricing information, including shipping, quality control, and customs clearance, is available. We prioritize IP protection throughout the part-production process to ensure your designs and models are completely secure. Our facilities include design for manufacturability (DFM) analysis, and our mechanical engineers are on hand to guide you.

Specified on time every time

We adhere to comprehensive quality control processes and protocols to keep your supply chain consistent and robust. Our manufacturing partners complete a review process before joining the supply chain cooperation. On-site quality engineers will frequently conduct audits to ensure they meet Anplocnc standards. Our in-house team checks parts’ functional and cosmetic specifications; we handle all customs clearance requirements and ensure on-time delivery.

Sourcing from Anpllo to reduce supply chain risk

Supply chain resiliency is critical, especially when you need parts on tight schedules and with specific certifications. We have a self-built factory to reduce your supply chain risk and provide procurement solutions that meet compliance requirements. Anpllo can provide the most comprehensive range of industrial 3D printing, CNC machining, injection molding, and sheet metal manufacturing services, providing consistent capabilities for your aerospace projects, no matter the scope.

FAQs

Factories working with Anplocnc for their supply chain must sign our Manufacturing Partner Agreement as part of their onboarding. The contract states that they are obligated to keep customer data confidential. Our General Conditions of Sale prohibit orders that misappropriate or infringe copyrights, patents, design rights, trademarks, trade secrets, and other intellectual property rights.

If your part does not meet specifications, you can file a dispute claim, and we will remanufacture your part or refund your order. You can contact our Customer Success Team for more details on how we handle disputes. At the same time, we complete a non-conformity report for parts that do not meet all requirements and follow up with the order, including root cause analysis and rapid corrective action.

If you would like to obtain a special material part not listed on our website, you can send a request to your account manager or contact [email protected].

Put your aerospace & aviation parts into production today.

Anpllo is dedicated to the critical work that our aerospace clients do on a daily basis. Our 72,000-square-foot manufacturing facility meets the high standards of the aerospace industry, and we offer a comprehensive selection of On-demand customized processing services.

Because parts used in aerospace projects often require quick turnaround, Anpllo has everything suppliers need for product development and manufacturing all in one place. You’ll reduce the number of vendors necessary for the project and deliver it on schedule. Our experienced team is well-equipped to understand your unique requirements and provide tailored solutions that meet your specifications. Together, we can drive the advancement of the Aircraft and Aerospace sector with top-quality components and unwavering commitment to excellence.

Visit our services page to learn more about our capabilities, or contact us to get started on your project.