Why processing aerospace parts using CNC machining technology

- Why processing aerospace parts using CNC machining technology

With the rapid development of the modern aviation manufacturing industry, CNC machining technology has become one of the key technologies for aircraft manufacturing. The progress of CNC machining technology has led to a change in aircraft design concepts, from part design to the overall, complex direction. Only developed countries worldwide have a long history of aviation manufacturing, especially since the design and manufacturing technology of large and complex aircraft structural parts have matured.

But with the development of various types of civil and military aircraft in various countries, the main aviation enterprises in each country in the aviation CNC machining technology also began to accumulate a lot of technical experience, solve a series of key technical problems, the initial formation of the key technical advantages represented by the manufacture of large and complex structural parts of aircraft. However, with the continuous development of the aviation industry, aviation parts CNC machining technology will face greater challenges. Therefore, we still need to continue to conduct deep research in the field of CNC machining technology to adapt to the rapid development of the industry’s footsteps. This article concerns why the aerospace industry must use CNC machining technology to process the relevant parts.

What is aerospace CNC machining?

Aerospace CNC Machining uses computer-controlled machines to manufacture parts for the aerospace industry. CNC machines are programmed with computer software and follow precise instructions to perform tasks such as cutting, milling and turning. These machines can produce various high-precision and repeatable parts, making them ideal for the aerospace industry, where accuracy is critical. CNC machining in aerospace allows rapidly producing highly accurate and complex parts, making it an important part of the industry’s manufacturing process. Aerospace CNC machining is used to manufacture assembly and repair parts for aircraft and space shuttles. In the aerospace industry, aircraft typically require CNC-machined parts, kits and components. Aerospace equipment and aircraft components require the best parts to make hinges, bushings, valves, fixtures or other custom parts in the highest quality metals. Titanium and fungible alloys are most commonly used for aerospace parts, but other parts include stainless steel, Inconel, aluminium, brass, bronze, ceramics, copper and other specific types of plastics.

Why do we use CNC technology in the aerospace industry?

The aerospace industry has very high and even stringent requirements for structural design, function, performance, product quality and reliability of products. Many new materials and structures are used mainly for aircraft components. National defence and market competition require significantly shorter development and production cycles for aerospace products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on aerospace manufacturing and requiring advanced manufacturing skills. Modern CNC machining is a key part of advanced manufacturing skills and has become a decisive key skill, especially in the aerospace manufacturing industry. The following advantages of CNC machining services make them very important in the aerospace industry:

Accuracy: CNC machines can produce high-precision parts, which is very important in the aerospace industry, where accuracy is critical.

Repeatability: CNC machines can produce parts consistently to ensure that each part meets the required specifications.

Speed: CNC machines can work quickly, resulting in fast part production.

Versatility: CNC machines can be programmed to produce various parts, making them versatile and suitable for various aerospace applications.

Cost-effectiveness: CNC technology is more cost-effective than traditional manufacturing methods because it can produce parts with fewer defects, resulting in less waste and rework.

The aerospace industry generally includes all kinds of air traffic, from large Boeing 747 jets carrying hundreds of passengers to spacecraft rockets designed to explore the International Space Station, the moon and even Mars. Spacecraft are designed to stay in outer space for months or even years. Given this long-term maintenance, they must be developed with incredible accuracy and precision. In this context, computer numerical control (CNC) is increasingly suited to this field.

Characteristics of CNC machining of aerospace parts

Compared with other industry products, aerospace-type parts have several significant features that determine the characteristics of CNC machining technology for aerospace parts and the development direction. These characteristics are mainly reflected in the following aspects.

(1) the product type is complex, with small batches and diversified characteristics. Due to the complex structure of modern aircraft, a wide variety of parts, at the same time, aircraft development is usually small batch production, so can not use large-scale assembly line production to improve efficiency and reduce costs, so the aviation parts CNC machining must also adapt to this feature.

(2) the structure tends to be complex and integrated, and the process is difficult complex machining process. Modern advances in CNC technology to promote the design of aviation parts tend to be complex and integrated, simplify the assembly, and improve structural performance, which also gives CNC machining technology has put forward higher requirements.

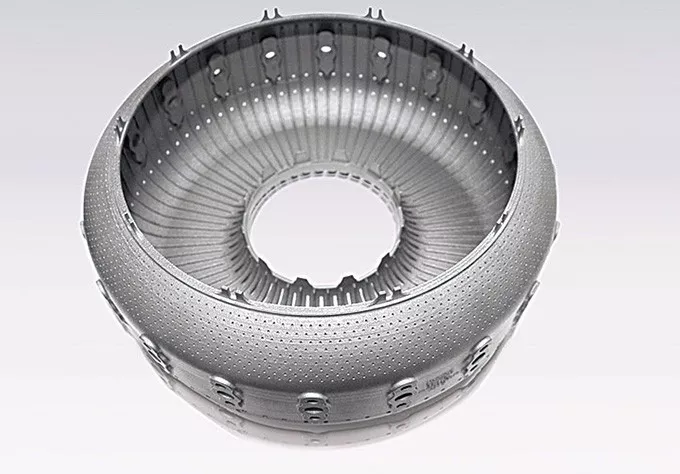

(3) thin-walled, large features, deformation control, is extremely critical. To control the weight of the aircraft, a significant feature of aircraft parts is the thin-walled design; on the other hand, the aircraft massification also makes the structure of the parts tends to be large, with many super-large parts, so the processing deformation has become a prominent contradiction. Figure 1 shows a typical aircraft thin-walled structural part – 787 nacelle beam.

(4) The material removal amount is large, and the cutting efficiency problem is prominent. Aircraft parts material removal is generally more than 90%, cutting efficiency on the production cycle and cost impact.

(5) High-quality control requirements. Due to the high safety requirements of aviation parts, the quality control of the product is very strict.

(6) Product material diversity. The development of materials, metallurgical technology, high-strength titanium alloys, composite materials and other applications are gradually expanding the scope and amount of aviation CNC machining technology to adapt to a wide range of requirements.

(7) large structural parts of the high value of the gross material, quality risk.

CNC machining mainly to solve aerospace parts processing, which difficult points

Most aerospace parts (such as fasteners) require tight tolerances and complex design. The specifications of each product part must be the same. The shape must remain constant even under extreme conditions. Aircraft parts are susceptible to high pressures, heavy loads, harsh chemicals, high temperatures and severe weather. CNC machining helps address the common challenges of CNC machining aerospace parts and allows computer-controlled machines with best-in-class accuracy and repeatability. This makes it possible to produce thousands of similar and complex aircraft components with tolerances of +/- 0.005. This includes the manufacture of parts that require self-lubricating features in high-wear applications. In addition, it allows for manufacturing high tensile strength parts for bearings.

Changing the demand for aerospace parts

The industry’s demand for parts is unique because it is constantly changing. Depending on when an aircraft is scheduled for maintenance or service, parts demand can jump from zero to thousands overnight. It is impractical to keep thousands of aircraft parts on standby. As a result, aerospace companies must rely on suppliers with a quick turnaround to ensure timely repairs. Some aircraft parts also require small runs, which can increase the cost of repairs and maintenance.

CNC machining makes it easy to machine the parts you need. No matter how many parts you need, our cost-effective CNC machining ensures your budget stays the same. This is even suitable for small-scale operations. Our quick turnaround ensures you can have your aircraft parts in weeks, not months. CNC machining helps us solve the common challenges of CNC machining aerospace parts.

Lower fuel consumption, longer range

The aerospace sector has increased the need for aircraft that fly longer distances but consume less fuel. The solution to this problem is to use advanced plastics as strong as metal. However, this is one-seventh to one-half the weight of metal. By using most plastics in the structure of the aircraft, the aircraft can be significantly lighter without sacrificing strength.

Lighter aircraft have longer ranges, lower maintenance costs and lower emissions. This improves efficiency overall. With CNC machining, we can easily produce the most technically advanced and complex parts. This production process also allows us to maintain tight tolerances.

Improved safety.

Passenger safety is a key issue in the design of aerospace components. The use of advanced plastics in aircraft interior manufacturing is increasing. This is due to their inherent flame retardancy and low smoke emissions. These two key factors play an important role in improving passenger survival. They are also extremely durable, withstand rigorous sterilization, and are easy to clean. These advanced plastics can be difficult to work with in inexperienced hands.

Summing up

This article has described why CNC machining is used to solve parts in the aerospace industry and what problems it can solve.

Anpllocnc can produce reliable and accurate aerospace parts as an aerospace CNC manufacturer using high-grade plastics or metal materials. Our best-in-class machines and tools help us solve the common challenges of CNC machining aerospace parts. Contact us today and place your order.