Analysis and control of deformation in CNC machining of complex monolithic structural parts

Table of Contents

- Analysis and control of deformation in CNC machining of complex monolithic structural parts

Introduction

Machining deformation of parts has always been one of the important problems plaguing the aviation manufacturing industry. Boeing has conducted a study on the economic loss of related problems. The report shows that the direct or indirect economic loss caused by machining deformation of parts reworked and scrapped exceeds 290 million dollars. With the continuous improvement of aircraft performance, the complexity of aircraft parts and the control of deformation requirements are also increased; part deformation control is no longer limited to simple frame, beam-type structure, complex overall structural parts of the deformation control is a new generation of aircraft parts deformation control focus and difficulty.

High-speed machining has been popularized in the aviation manufacturing industry; cutting forces and cutting heat on the impact of CNC machining deformation compared to the impact of the initial residual stress in the blank can be ignored. The main points of part deformation control gradually develop in the direction of stress distribution, material mechanics, Etc. Qin et al. established an analytical model of machining deformation caused by residual stresses in parts based on simple beam parts and quickly and accurately determined the lowest deformation position of simple beam parts through model analysis. The effect of cutting force and residual stress on the machining deformation of the part is analyzed by establishing the mechanical model of cutting workpieces by finite element.

There are more conclusions of deformation control analysis for simple structural parts. However, it is not easy to give a single deformation control method by clear mathematical calculation in the actual CNC machining process of complex integral structural parts, which are designed as a whole with traditional frames, beams and supports. This paper explores a more general deformation control method in the machining process of complex monolithic frame parts based on material internal stress, force balance and moment balance. The design of the part processing scheme, the optimization of the rough machining form and ageing so that the part is fully deformed, in-depth elaboration and exploration of the correction of the benchmark, easy-to-deform first processing and other options, and finally come up with a better processing scheme for deformation control of integral complex structural parts.

1. Analysis of the deformation mechanism

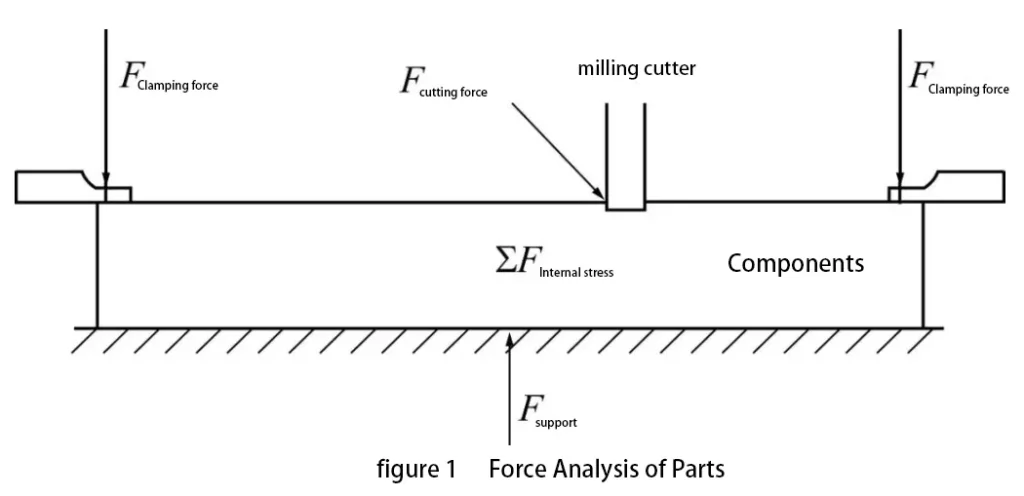

In the natural state, the part is in equilibrium, i.e. ∑F=0. At this time, the part may be deformed, and ∑F internal stress is equal to the yield stress F generated by the part deformation, and the part is in equilibrium. In the CNC machining process, the massive removal of metal material seriously affects the distribution of the metal stress field, and the internal force balance and moment balance of metal material are seriously out of control. CNC milling process in the parts of the force shown in Figure 1, where ∑ F internal stress is the combination of various stresses inside the part (prompting the part to uncontrollable deformation); ∑ F external force is the combination of all forces applied to the external parts during the machining process, including the machine plane on the parts of the support force F support force, pressure plate, vacuum adsorption, bolts and other compression methods acting on the parts of the clamping force F clamping force and The combined force of external forces such as the cutting force F cutting force generated by the milling tool during milling due to cutting heat and material removal can suppress the effect of ∑F internal stress on the material so that the part cannot be deformed and is in a stable state during CNC machining.

After the part is machined and unloaded, ∑F external force is removed, the overall force state of the part suddenly changes, and the part is deformed unpredictably under the action of ∑F internal stress. When ∑F equals 0 again, the deformation of the material stops and a state of force and moment equilibrium is reached within the material. The ∑F internal stress is inevitably generated during the CNC machining of the part, which is related to the material state and machining scheme and can only be reduced but not eliminated.

In the rough machining process, the material removal ratio is high, the removal efficiency is fast, and most of the material can be removed in a short time, which will lead to a larger internal material stress ∑F internal stress, and this internal stress will eventually lead to a larger machined deformation of the part after rough machining.

From the analysis of parts structure, with the improvement of aircraft parts design level, complex integral parts will be designed to avoid parts deformation according to their structure in the early stage of design, such as reasonable rib distribution and design connection, so the parts themselves have a certain deformation resistance.

After the rough machining of the part through the ageing process, the internal stress tends to be smooth, the material removal when finishing is small, and with the uniform removal of the internal and external shape of the part, will not have a greater impact on the distribution of internal stress of the part, the internal stress caused is reasonable and will not exceed the yield limit of the part’s structure more. Therefore, the part deformation caused by changes in the internal stress of the part is smaller.

2. Aging process

The ageing process is arranged after rough machining, which is the process of internal stress adjustment of the part. Ultrasonic, heat treatment, or vibration methods can be used to remove residual stresses, such methods are mainly through the elimination of internal residual stresses to adjust the internal stresses of the part to reduce the impact of internal stresses on the part deformation, but only part of the residual stresses can be removed.

In this paper, we focus on adjusting the internal stress of parts by ageing. After rough machining, the parts are deformed under ∑F internal stress. However, the action of ∑F internal stress is not instantaneous but changes continuously with the release of internal residual stress in the material. Even after a long time, ∑F’s internal stress changes, but the deformation caused by the internal stress is smaller and does not affect the part.

The overall deformation of the part is not affected. The general ageing process cycle is long, and with the material, part structure, environmental temperature and humidity and other factors, common ageing methods are natural ageing, high and low-temperature ageing, heat treatment ageing and vibration ageing, Etc., which natural ageing is the lowest cost, the most simple operation method, but the cycle is long. Other methods require additional equipment and processes but can shorten the ageing cycle. In order to finally control the deformation of the part, the ageing process should be arranged after rough machining so that the part is fully deformed.

3. Reference correction

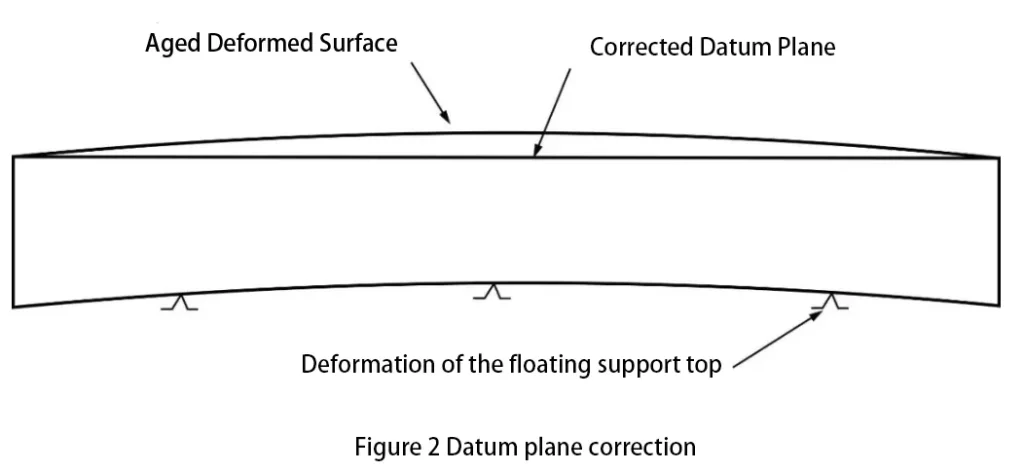

Benchmark correction is the core of part deformation control. After rough machining and natural ageing, the internal stress of the part is in equilibrium, rough machining material removal, so the resulting stress deformation is larger, the finishing allowance is relatively small and evenly distributed, the stress deformation after processing is less, and basically within the design requirements of the tolerance.

Finishing process machining parameters, cooling, clamping force and other factors on the part deformation are also greater. Machining parameters, cooling, Etc. can be better controlled through the process. However, the clamping force on the finishing deformation is the most difficult to control. This paper mainly focuses on the benchmark correction of finishing clamping stress control to achieve stress-free clamping, including positioning plane correction and positioning reference correction.

3.1 Positioning plane correction

The positioning plane is the plane that plays the main role in supporting the part during the clamping process. Due to the different structures of the parts, the positioning plane can be either plain or composed of multiple planes together. However, the shaped surface is not conducive to correcting the positioning plane, so the first finishing positioning plane after natural ageing is set to a flat structure as far as possible, avoiding setting to a curved surface or a bevelled surface.

In the positioning plane correction process, you should try to avoid the impact of clamping force on the part blank; clamping force only restricts the freedom of the part and does not cause deformation of the part, that is, stress-free clamping compression. In the production process, the stress-free clamping methods are as follows.

(1) Solid filler filling method

By filling plaster, latex and other filler materials in the shape of the part and waiting for the material to cure for the benchmark correction and subsequent finishing of the part. This method does not require assistance, simple operation, easy to achieve, but the filler can not be repeatedly used; complex parts after CNC machining filler is difficult to remove, and the filler is easy to corrode endomorphic surface, triggering the part surface quality defects.

(2) Local aluminium foil pad levelling method

Through the application of a single thickness of 0.1mm, an aluminium foil stacked layer will be deformed parts and work with the gap generated by the support of the pad flat and pressed to avoid the clamping force caused by the stress deformation of the parts. The advantage of this method is that the aluminium foil is low-cost, reusable and simple to operate. However, with the use of aluminium foil laminated cushion level, there is a gap between the layers, poor stability, and correction of the plane in the process of changes in the state of the parts, resulting in poorly corrected flatness, affecting the plane positioning effect.

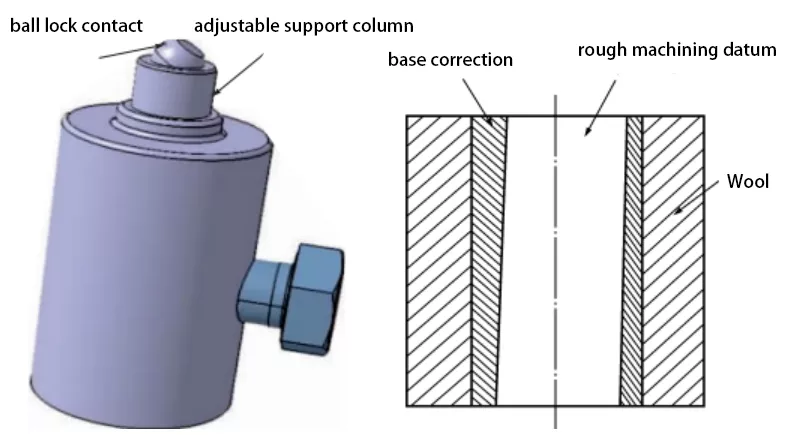

(3) floating support compression method

Three for a single floating support structure, floating support height and support direction can be adjusted according to the deformation of the wool, adjusted by the pressure plate compression; at this time, the pressure plate and floating support compression parts play a fixed role, and the clamping force will not cause parts deformation.

The floating support pressing method has high applicability to the processing scheme of process lug pressing after rough machining, which can easily and quickly fix the deformed wool and facilitate the subsequent correction of the reference work.

Through the correction of the positioning plane, the part will not be deformed twice during the clamping and pressing process, i.e. the internal stress ∑F internal stress of the part will not change after clamping, and the clamping force only plays the role of limiting the movement.

3.2 Correction of positioning datum

The positioning origin is the origin of the machining coordinate system, and the coordinate origin also needs to be corrected after the part has been aged. As the part deformation processing origin may be offset, if not corrected easily caused by insufficient roughing allowance, the part can not be finally processed into shape. Multi-station processing parts need to straighten and set up the coordinate processing system; if the point of origin is not accurate, it is easy to cause a large repeat positioning error, affecting the accuracy of the parts.

(1) Right-angle edge correction

When the part processing origin for the right-angle edge, right-angle edge correction after the completion of the correction of the positioning plane, the right-angle edge for the benchmark correction of CNC milling processing. When correcting the right angle edge, it should be noted that the single correction amount should not be too large; trimming out part of the straight edge can be used for straightening and correcting, without milling out all the straight edge, to avoid uneven distribution of the endomorphic residual caused by the straight edge correction.

(2) reference hole correction

In the process of CNC parts processing, the reference hole as the positioning and processing of the origin of the processing program accounted for most. Figure 4 shows the correction of the reference hole because the correction of the reference hole needs to be removed along the perimeter of the hole, avoiding the uneven distribution of the endomorphic residue caused by the correction of the residue in a single direction and at the same time, using the corrected reference hole as the positioning reference can greatly improve the repeated positioning accuracy of multi-station machining of the part.

The correction of the positioning plane before finishing the part achieves stress-free clamping of the finishing part and avoids the deformation caused by the clamping force. Correcting the positioning datum avoids the error caused by rough machining deformation and improves the repeatability of multi-station machining parts. Based on the double correction of the positioning plane and positioning reference, the influence of roughing deformation on the finishing parts is avoided.

4. Easy to deformation where first processing

The complex overall part structure generally exists at the same time high thin edge structure, overhanging open structure, protruding unsupported structure and other difficult machines easy to deform characteristics of the parts. Processing easy to deformation first is based on the structure of the part proposed to take into account the macro and micro processing of the parts deformation control program by adjusting the processing order of the local features of the part to achieve the deformation control of parts processing.

Macroscopic deformation control is based on the overall structure of the part, analysis of the areas and features prone to deformation, such as open structure parts rough machining priority processing of open areas, so that it is fully deformed; simple beam structure parts first processing unsupported overhang area; high thin bar edge structure processing, first increase the processing allowance of the bottom of the high thin bar, priority processing of poor rigidity of the top high thin bar edge. By reasonably optimizing the machining sequence of the part, the machining deformation caused by the lack of rigidity of the part can be avoided.

The microscopic deformation control solution minimizes the variation of ∑F internal stress by adjusting the machining sequence of endomorphic features during the finishing process of the part. The smaller the variation of ∑F internal stress, the smaller the deformation of the part after finishing, combined with ageing to control deformation, and finally realize the control of machining deformation of complex structural parts.

Conclusion

(1) The rough machining process is the main process of stress deformation of the part; rough machining removes more than 90% of the machining allowance of the part, and the internal stress of part ∑F internal stress changes more when the external clamping stress is removed, the part deformation occurs. When finishing, the part within the shape of the uniform balance and small amount of residual material removal, after finishing, ∑ F internal stress changes less, the part structure itself there is a certain yield resistance, after finishing ∑ F internal stress caused by the part deformation is smaller.

(2) The ageing process is necessary to fully deform the part after rough machining so that the internal stress of the part material redistributes and achieves force balance and moment balance. Ageing deformation is necessary for controlling ∑F’s internal stress during finishing. If the ageing is insufficient, the change of ∑F internal stress caused by finishing will be very large, and the deformation of rough machining will be carried into the finishing process, eventually leading to the loss of control of part deformation.

(3) The datum correction process is the main process to eliminate the impact of clamping force on the part deformation through the datum correction to make the part in the finishing clamping ∑ F internal stress = 0, to achieve the finishing parts of the stress-free clamping, the clamping force on the part only clamping effect, will not cause the part deformation force. Through the datum correction, the influence of rough machining part deformation on part finishing is eliminated, and the repeat positioning accuracy of multi-station finishing parts is improved.

(4) Machining the easily deformed part is the control strategy of the overall machining scheme for part deformation. According to the structural characteristics of the part, the easily deformed structural area is machined first during roughing to make it fully deformed before finishing. In the finishing process, the area’s structural weakness and poor rigidity are machined first, which can reduce the influence of the part’s structural characteristics on the part deformation.