The advantages and development of CNC fabrication technology for high-end precision manufacturing

- The advantages and development of CNC fabrication technology for high-end precision manufacturing

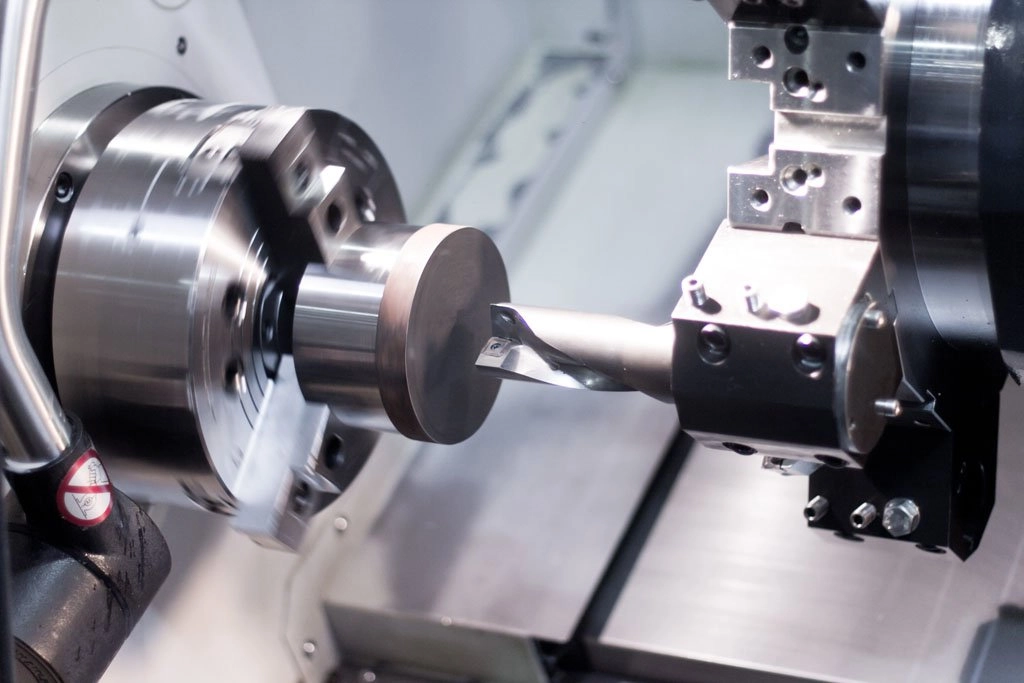

CNC fabrication (numerical control machining) uses digital control systems on the processing machine to complete the entire part processing. It also refers to a process method of machining parts on a CNC machine tool. The process protocols of CNC machines and traditional machine tool machining are generally consistent, but significant changes have also occurred. Machining method of controlling the displacement of parts and tools with digital information. It is an effective way to solve the problem of a variable variety of parts, small batches, complex shapes, and high precision and achieve efficient and automated processing. It is also a sign of the development of the national manufacturing industry.

What is CNC fabrication?

CNC fabrication means that the control system issues a command to make the tool make various movements by the requirements, in the form of numbers and letters to indicate the shape and size of the workpiece and other technical requirements and processing process requirements for processing. It generally refers to machining parts on a CNC machine tool. A CNC machine tool is a computer to control the machine tool, used to control the machine tool computer, whether a special computer or general-purpose computer, collectively known as the CNC system. CNC machine tool movement and auxiliary action are controlled by the instructions issued by the CNC system.

The programmer prepares the instructions for the CNC system according to the material of the workpiece, processing requirements, the characteristics of the machine tool and the instruction format (CNC language or symbols) specified by the system. According to the program instructions for the servo device and other functional components, the CNC system is issued to run or final break information to control the machine tool’s various movements. When the parts of the processing program are over, the machine will automatically stop. Any CNC machine tool in its CNC system, if no input program instructions, CNC machine tools can not work. Machine tool-controlled actions include machine start, stop; spindle start and stop; rotational direction and speed change; feed motion direction, speed, way; tool selection, length and radius compensation; tool replacement, coolant on, off, Etc.

The principle of CNC fabrication

Do you know the principle of CNC machine tool processing? The CNC fabrication centre controls the movement of the machine tool through the CNC program, and the program controls the machining process of the workpiece.

CNC machine tools are operated by the program, eliminating many manual operations. So the question arises, how does the program drive the machine tool? First, the program is driven by the tool compensation, interpolation, servo system and PLC to accomplish the machine motion. The workpiece machining program, represented in text format, is converted into a program-based data structure that describes the data information following a program segment. This includes the storage order and format of coordinate values such as XYZ, spindle speed, feed rate, M-code, g-code, tool post-processor, and cycle call data flags.

The part machining program is processed according to the part contour, and the CNC machine controls the toolpath. Before machining, the part contour must be converted into a toolpath. Tool trimming is the process of this conversion. The displacement of the feed axis per unit time is calculated according to the interpolation period, straight line, linear, circular arc and other components specified by the motion system, with speed given by the program, so that the servo system can achieve the forming motion.

PLC controls the machine’s sequential control, travel switches, and the CNC’s internal sensor buttons, provided that the switch signal status of the relays controls the spindle start and stop, tool change, and workpiece clamping unclamping, cooling and lubrication systems, Etc. In a prescribed logical sequence.

The principle of CNC fabrication is also the process of CNC fabrication: First of all, the geometric and process information of the machined part is digitized, i.e. the control and operation of the relative motion trajectory of the tool and workpiece, the change of spindle speed and feed rate, the switching of coolant, the replacement of workpiece and tool, Etc. , are compiled into a machining program according to the specified code and format, and then the program is sent to the CNC system. The CNC system first makes the corresponding calculation and processing according to the program’s requirements; finally, it issues control commands to coordinate the coordinate axes, spindles, and auxiliary movements to achieve the relative movements of the tools and workpieces automatically complete the machining of the parts. Among them, the six devices that need attention are.

1, programming and program carrier, CNC program is a CNC machine tool to automatically processes the parts of the work instructions.

2, input device, the role of the input device is the program carrier (information carrier) on the CNC code passed and stored in the CNC system.

3, numerical control device, numerical control device is the core of CNC machine tools.

4, drive device and position detection device, the drive device accepts the command information from the CNC device.

5, auxiliary control device, the main role of the auxiliary control device is to receive the switch command signal output from the numerical control device.

6, the body of the machine tool can meet the requirements of CNC machine tools and give full play to CNC machine tools.

Features of CNC fabrication

CNC CNC fabrication process also abides by the laws of mechanical machining cutting, and the normal machine tool processing process is largely the same. As it is the application of computer control technology in the machining of automated processing, and thus has a high processing efficiency and high precision, processing technology has its unique features; the process is more complex, and the work step arrangement is more detailed and thorough.

CNC CNC fabrication process includes the selection of tools, cutting parameters and the determination of the design of the tooling process route.

CNC CNC fabrication is the basis of CNC programming and the core, only a reasonable process to compile a high-efficiency and high-quality CNC program. The standard for measuring the good or bad CNC program is the minimum processing time, the minimum tool loss and processing the best results of the workpiece.

The CNC fabrication process is a part of the overall processing process of the workpiece or even a process. It has to cooperate with other before and after processes to meet the overall machine or mould assembly requirements finally so qualified parts can be processed.

The CNC fabrication process is generally divided into roughing, medium roughing clearance processing, semi-finishing and finishing and other work steps.

CNC fabrication parts of the steps

1、Analysis of the part diagram to understand the general situation of the workpiece (geometry, workpiece materials, process requirements, Etc.)

2, determine the CNC fabrication process of the part (processing content, processing route)

3, the necessary numerical calculations (base point, node coordinates calculation)

4, the preparation of the program sheet (different machines will vary, comply with the manual)

5, program verification (enter the program into the machine and graphical simulation to verify the correct programming)

6, the workpiece for processing (good process control can be good to save time and improve the quality of processing)

7, workpiece acceptance and quality error analysis (inspection of the workpiece, qualified into the next. (Failure to find the cause of error and correction method through quality analysis).

CNC lathe processing is more suitable for the processing of which parts

1. Suitable for processing various small and medium-sized parts. With the gradual decline in manufacturing costs of CNC lathe processing, many parts have appeared at home and abroad for processing. Dealing with small-batch single-piece production can shorten the program’s debugging time and the tools’ preparation time.

2. Higher requirements for the precision of the parts. CNC machine tools with good rigidity, high manufacturing accuracy, accurate tooling, and convenient size compensation can process parts with high dimensional accuracy.

3. Parts with small surface roughness. In the workpiece and tool material, the finishing allowance and tool angle are constant; the surface roughness depends on the cutting speed and feed rate. Ordinary machine tools are constant speed; different cutting speed is different. For example, a CNC lathe has constant linear speed cutting. When the end diameters differ, the same linear speed can be used to ensure the surface roughness value is small and consistent. When processing different surface roughness of the surface, choosing the roughness of the small surface to obtain a lower feed rate and the roughness of the larger surface to obtain a larger feed rate, the variability is very good, which is difficult to achieve with standard machine tools.

4. The contour of the more complex parts. A straight line or arc can approximate any plane curve. CNC machine tools with circular interpolation functions can handle a variety of complex contour parts.

The development trend of CNC fabrication

1, CNC fabrication precision development

The core of CNC fabrication is mainly reflected in the dimensional accuracy, profiling accuracy and surface quality requirements. At present, the precision of precision EDM machining has been comprehensively improved. Size processing requirements up to 2-3μ m, the bottom angle R-value can be less than 0.03mm. The best processing surface roughness can be lower than Ra0.3μm m; through the use of a series of advanced processing technology and process methods to achieve the mirror surface processing effect, it can complete the micro connector, IC plastic sealing, cell phones, CD boxes and other high-precision mould parts of EDM processing.

2.CNC fabrication is developing towards intelligence

It is one of the development trends of intelligent manufacturing technology in the 21st century. Intelligent manufacturing technology (IMT) will be artificial intelligence in all aspects of the manufacturing process by simulating the intelligent activities of human experts, replacing or extending part of the mental labour in the manufacturing system. During the manufacturing process, the system can monitor its operating status and adjust its parameters automatically when subjected to external disturbances or internal stimuli to achieve the optimal state and self-organization capability. The new CNC EDM tool adopts fuzzy and expert system intelligent control technology. The fuzzy control technology is to judge the state of the EDM gap by computer monitoring and automatically selects the machining conditions that can achieve the highest machining efficiency within the range of maintaining the stability of the electric arc. Automatic monitoring of the machining process to achieve the most stable control technology for the machining process. The expert system in human-machine dialogue mode can automatically generate machining programs and select the best combination of machining conditions for machining after reasonable input of set values according to machining conditions and requirements.

The machining process is automatically monitored and adjusted online to achieve optimal control of the machining process. When testing machining conditions, experts can automatically calculate and configure the best conditions by inputting indicators such as machining shape, electrode and workpiece material, machining position, target roughness value, electrode scaling ratio, shaking method, taper value, Etc. The application of expert intelligence technology makes the machine easier to operate, and the operator’s technical level requirements are lower.

3. CNC precision machining is moving toward automation

The successful application of automation technology not only improves efficiency and ensures product quality but also can replace people in dangerous situations to complete the work. Large-scale production automation can be through the automatic conversion of machine tools, automatic machine tool applications, a special combination of machine tools and automatic production lines. NC, MC, CAM, FMS, CIM, IMS, Etc can achieve automation of small production runs. In the future implementation of automation technology, more attention will be paid to the role of people in the automation system. At the same time, automation is beginning to be oriented towards small and medium-sized enterprises, with an economical and practical starting point to meet the evolving demand for product diversification and individualization. The automatic measurement and alignment, automatic positioning, and continuous machining of multiple workpieces of CNC EDM machines have already given full play to their automation performance. The automatic operation process does not require human intervention, which can improve machining accuracy and efficiency. The most advanced CNC EDM machine tools have an electrode library and standard electrode fixture. As long as the electrode is loaded into the tool magazine before machining and the machining program is prepared, the whole EDM process can run automatically daily with almost no manual operation. The automatic operation of the machine reduces the operator’s labour intensity and improves production efficiency.

4.CNC fabrication is developing in information technology

Information, material and energy are the three main elements of the manufacturing system. With the application of computer, automation and communication network technology in the red manufacturing system, the role of information is increasingly important. The information input in the manufacturing process has become the main factor in determining the cost of the product. The manufacturing process’s essence is collecting, inputting, processing and handling various information resources in the manufacturing process. The final product can be regarded as the material expression of information so that information can be regarded as an industry, including in the manufacturing industry.

For this reason, some enterprises have started to use network technology, computer networking, information highway, satellite data transmission, Etc. Realize off-site production. Make production decentralization and networking to meet the needs of the 21st century highly flexible production.

5. CNC precision machining integration

Integration is the role of the past independent operation of multiple unit systems integrated into a new system that can work in coordination and is more functional. Integration is not simply connected; it is through the unified planning and design, analysis of the original unit system functions and interrelationships, optimization and reorganization to achieve. The purpose of integration is to realize the functional integration of manufacturing enterprises. Functional integration should be realized with the help of modern management technology, computer technology, automation technology and information technology while emphasizing the integration of people. Because it is impossible to have no people in the system, the effect of system operation and the business philosophy, operation mechanism and management mode of the enterprise are related to people. Integrating management and people should also be emphasized in the integration of technology. Integrated production will become the dominant production method in the 21st century.

Summing up

CNC is a method of regulating the fitness movement of the CNC lathe with intelligent control and information content of an electronic computer. It has the characteristics of high speed, stability, multi-purpose, intelligent system and open way. It is also the main indicator value to measure the progress of national processing technology and international status, information technology intelligence.

So in retrospect, the traditional machinery and equipment processing manufacturing industry is not only inefficient, and there are often some uncontrollable factors, making people’s work far less than expected, the amount of labour, the high requirements of technical personnel, so there will be a certain degree of regularity and operational limitations. Therefore, the application of intelligent CNC machine processing technology becomes crucial; it not only has a high efficiency but also can and repeatedly complete some high precision; human factors are blind and can not complete the small work. CNC can be simple, accurate, fast, and efficient, and it can be done by changing the g code and manipulating the computer language due to human factors. The costs and assets necessary for CNC fabrication will require expensive multi-part and more traditional machinery and equipment processing. The future development of CNC fabrication requires the constant pursuit of perfection. It is a high-tech industry that requires continuous development.

With the globalization of the economy, the key industries and core manufacturing areas of CNC fabrication demand structure and level will change dramatically. Automotive, high-speed rail, aerospace, energy, shipbuilding and other industries need high precision, high efficiency, automation, energy saving and emission reduction of a new generation of CNC technology to process high-precision parts.